Ultralow-sheet-resistance metal aluminum film

A metallized aluminum, ultra-low-side technology, applied in the field of capacitors, can solve problems such as the inability to guarantee the reliability of capacitors, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

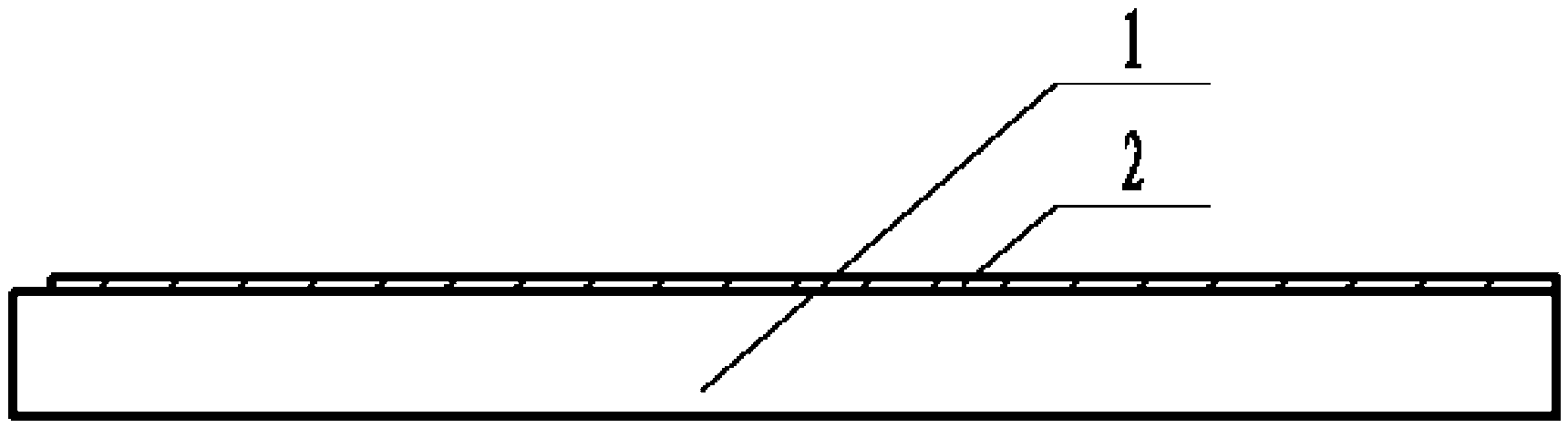

[0020] Such as figure 1 As shown, an ultra-low square resistance metallized aluminum film is composed of a base film 1 and a metallized aluminum film layer 2. The square resistance of the metallized aluminum film layer 2 is 0.25~0.65Ω / □, while the conventional metallized aluminum film The square resistance of the layer is 2~4Ω / □, that is, the thickness of the metallized aluminum film layer 2 is about 7 times that of the conventional metallized aluminum film, and the metallized aluminum film layer 2 is greatly thickened, which means that the vacuum evaporation metallization In the case of aluminum film, more aluminum should be deposited on the base film in the same time.

[0021] The base film 1 is an organic film, which can be selected as a po

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap