ZnO Schottky diode

A technology of Schottky diodes and metal electrodes, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low cut-off frequency, limited application occasions, large substrate series resistance, etc., and achieve high cut-off frequency, low price, The effect of strong radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

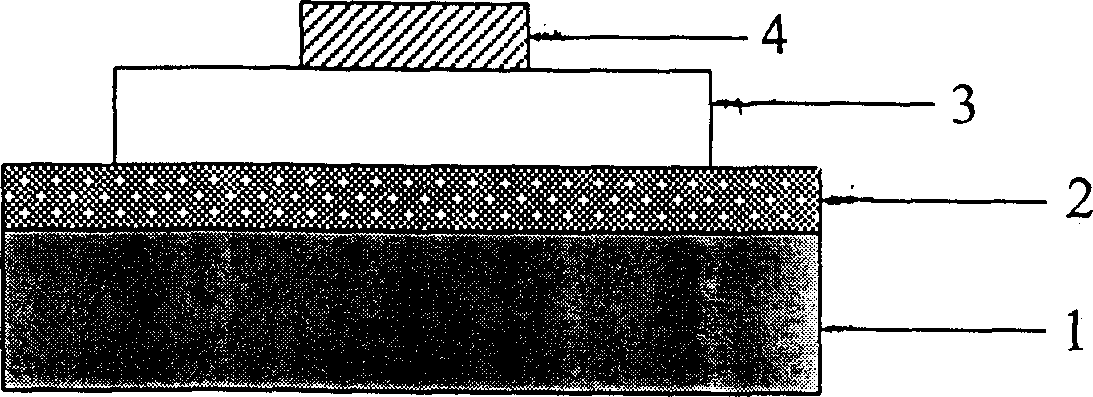

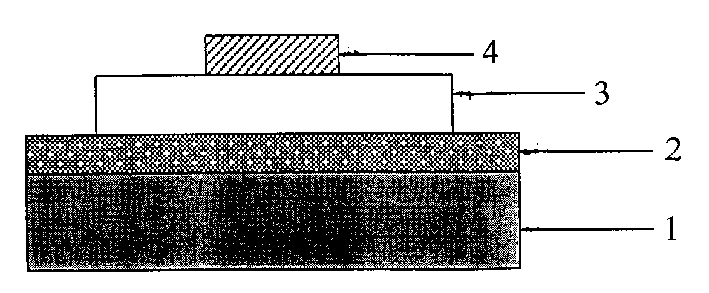

[0009] refer to figure 1 The ZnO Schottky diode of the present invention is formed by sequentially depositing a first metal electrode layer 2 , a ZnO crystal film epitaxial layer 3 and a second metal electrode layer 4 on the front surface of a substrate 1 from bottom to top. The substrate can be silicon, metal or glass. The thickness of the ZnO crystal film epitaxial layer is 0.3-1 μm. The first and second metal layers can be any metal. Generally, it is better to use aluminum for the first metal layer and platinum for the second metal layer. .

[0010] During preparation, the substrate is first cleaned according to conventional methods, and then the first metal layer, such as an aluminum film, is deposited on the substrate by vacuum evaporation, and then the ZnO crystal film layer is deposited on the aluminum film by magnetron sputtering deposition, and the A photolithographic process produces a second metal electrode layer, such as a platinum electrode, on the ZnO film.

[0

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap