Speed limiter of monorail conveyor

A technology of monorail conveyor and speed limiter, which is applied in the direction of mechanical equipment, brake type, drum brake, etc., can solve the problems of complex structure and poor installation flexibility, and achieve the effect of flexible installation, consistent speed limit effect and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

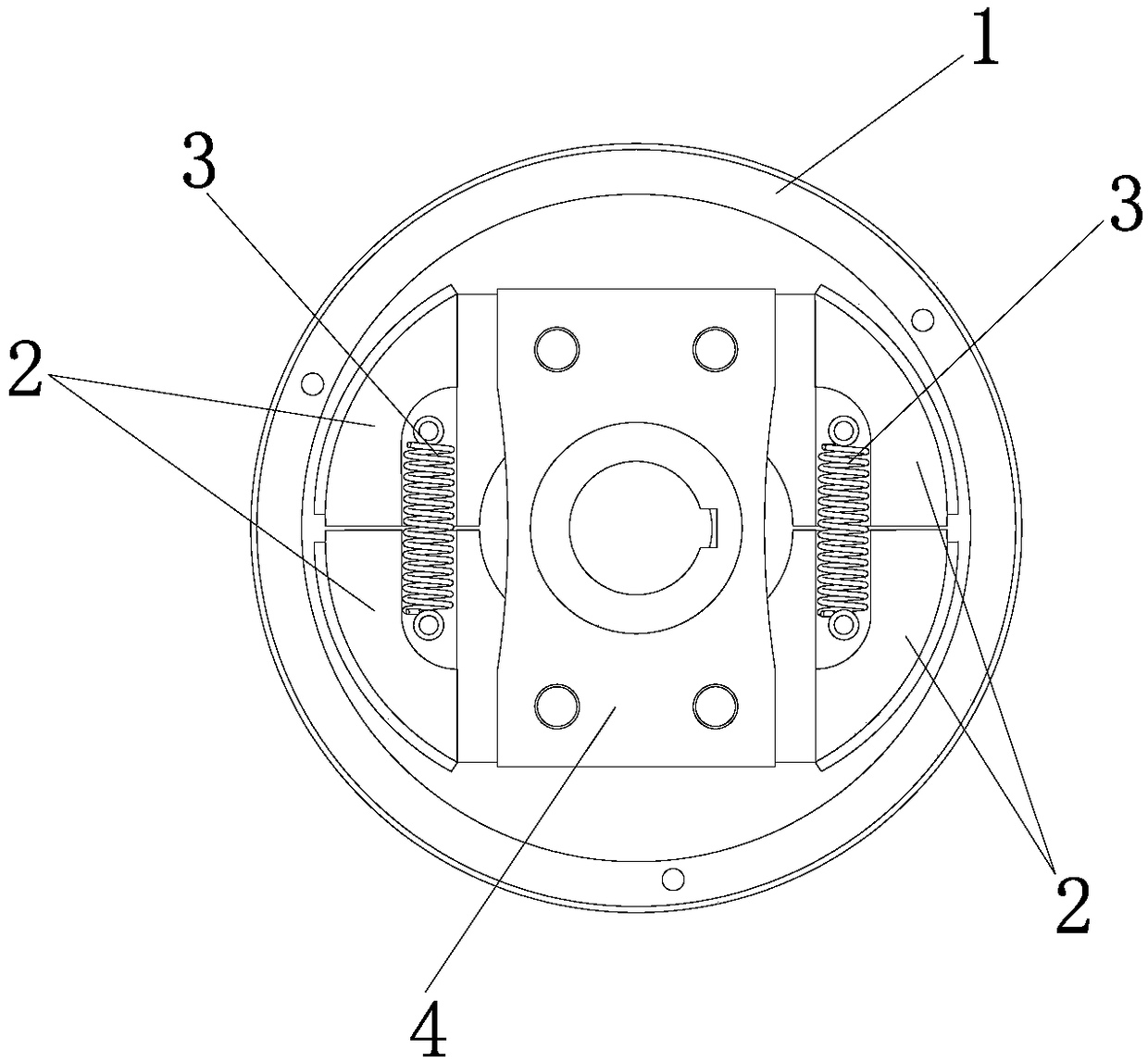

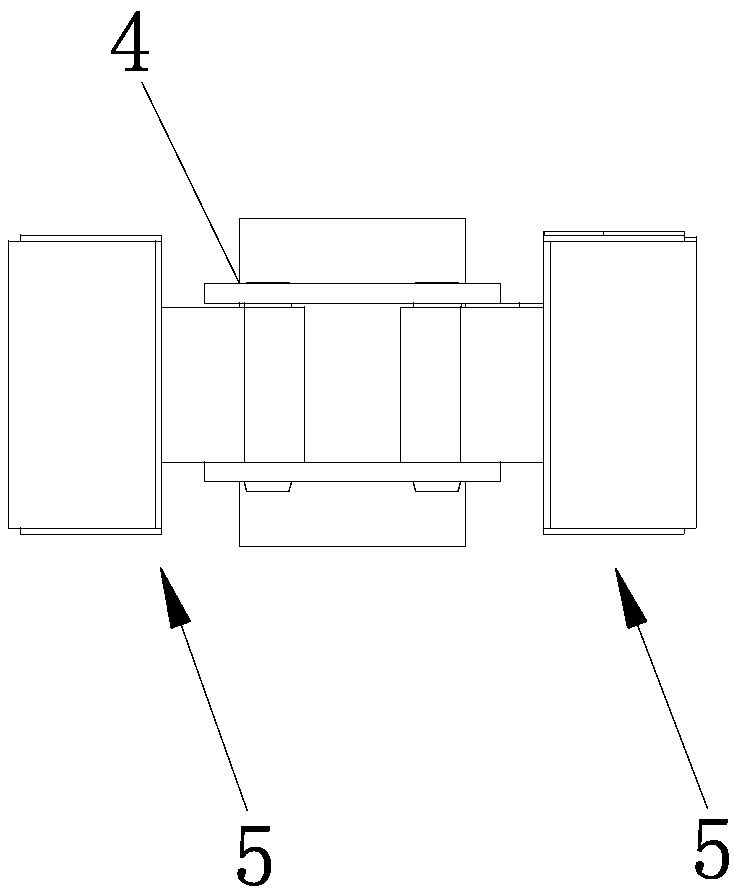

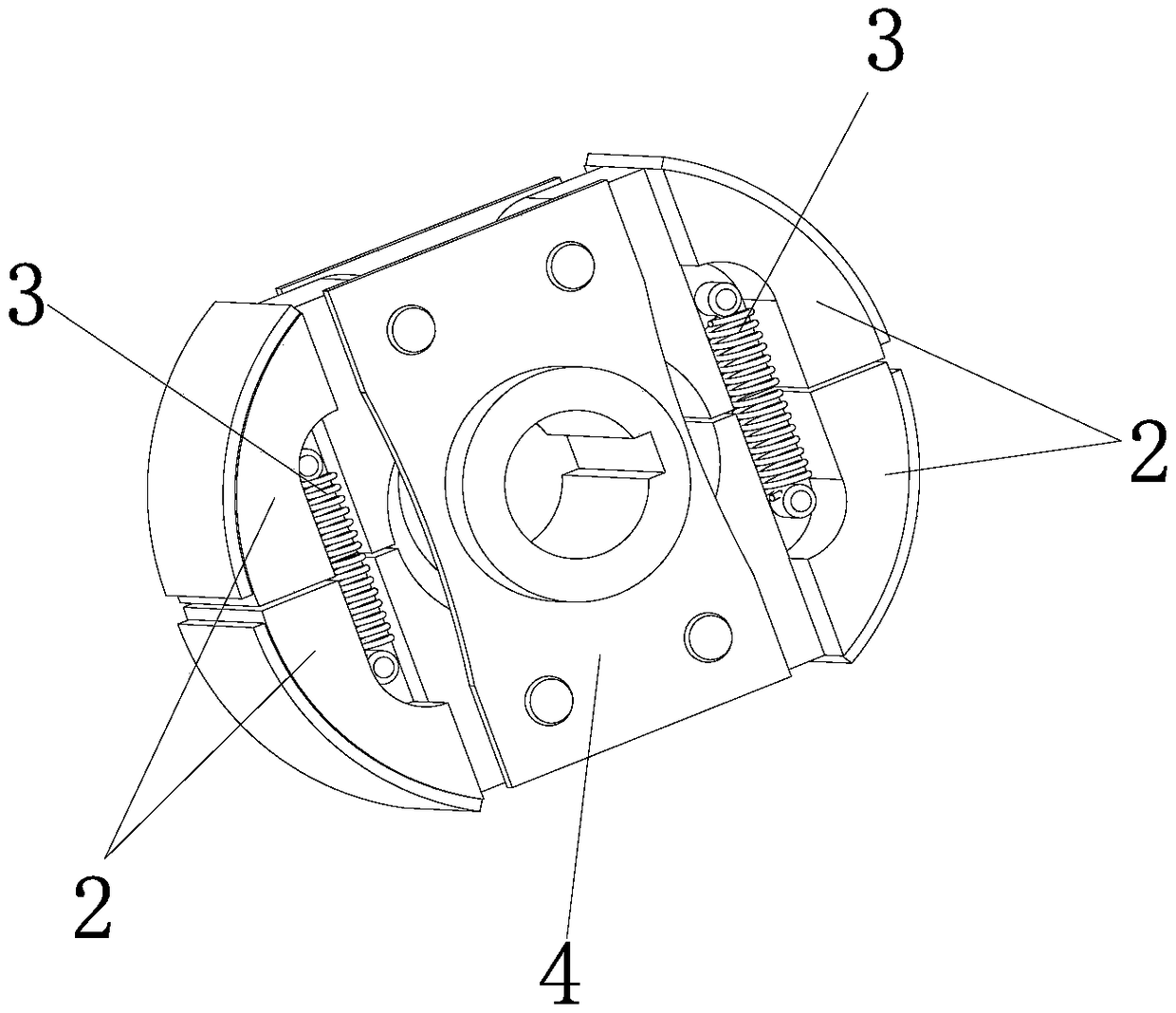

[0032] see Figure 1-Figure 10 , the speed governor of the monorail conveyor in this embodiment includes a brake drum 1 fixedly arranged on the frame and a brake mechanism arranged in the brake drum 1; wherein, the inner circular surface of the brake drum 1 is located at Outside the braking boundary circle; the braking mechanism includes a turret 4 and two groups of brake assemblies 5 arranged on the turret 4, the center of the turret 4 is connected with the running shaft of the monorail conveyor, and the two groups The moving shoes 2 are symmetrically arranged on the turret 4, and each group of brake assemblies 5 includes two brake shoes 2 and elastic elements 3; the two brake shoes 2 of each group of brake assemblies 5 are arranged symmetrically, and the two One end of each brake shoe 2 that is far a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap