Vortex street throttling integrated gas-liquid two-phase flowmeter and application method thereof

An all-in-one, flow meter technology, applied in the direction of detecting the dynamic effect of fluid flow, volume flow measurement device, liquid/fluid solid measurement, etc. problems, to achieve the effect of reducing the number of pipe openings and sensors, reducing the overall length, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

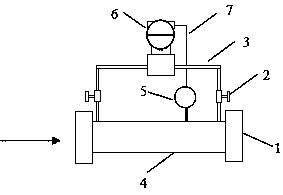

[0021] This embodiment provides a vortex throttling integrated gas-liquid two-phase flowmeter, such as figure 1 As shown (the arrow in the figure is the direction of liquid flow), it includes an intelligent differential pressure flow transmitter 6 arranged up and down and a vortex street throttling measuring device 4, and the vortex street throttling measuring device 4 includes a horizontally placed throttling pipe 8 , the two ends of the throttling pipeline 8 are respectively connected to the intelligent differential pressure flow transmitter 6 through two pressure guide tubes 3; The transmitter 5 is connected to the intelligent differential pressure flow transmitter 6 through the signal line 7;

[0022] The working principle of the vortex throttling integrated gas-liquid two-phase flowmeter is as follows:

[0023] The vortex street throttling measurement device 4 collects the vortex frequency and fluid temperature generated by the fluid passing through the throttling pipeline

Embodiment 2

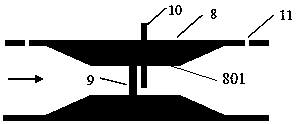

[0027] On the basis of Example 1, such as figure 2 As shown (the arrow in the figure is the direction of liquid flow), the vortex throttling measurement device 4 also includes a vortex generator 9, a vortex temperature integrated detection probe 10 for detecting vortex frequency and fluid temperature, a differential pressure gauge Hole 11; the cavity of the throttling pipe 8 is a Venturi structure, the vortex generator 9 is installed at the roar 801 in the middle of the Venturi structure, the vortex street temperature integrated detection probe 10 is located downstream of the vortex generator 9 and one end of the probe is vertical Inserted at the bellow 801, the other end is connected to the vortex temperature transmitter 5, and the differential pressure measuring hole 11 is used to connect the pressure guiding pipe 3.

[0028] Specifically, the throttling pipeline 8 is an improved Venturi structure, which is symmetrical about the central line of the waist, such as figure 2 As

Embodiment 3

[0031] On the basis of Embodiment 2, the vortex street temperature integrated detection probe 10 integrates a vortex signal detection sensor and a temperature sensor into an integrated package for detecting vortex frequency and fluid temperature.

[0032] In this embodiment, the integrated design of the vortex sensor and the temperature sensor reduces the number of pipe openings and sensors, and further simplifies the structure.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap