A transformer respirator with automatic dehumidification function

A respirator and transformer technology, applied in the direction of transformer/inductor cooling, transformer/inductor components, electrical component structure association, etc., can solve the problems of potential safety hazards, difficult management, and scrapping of respirator in transformers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

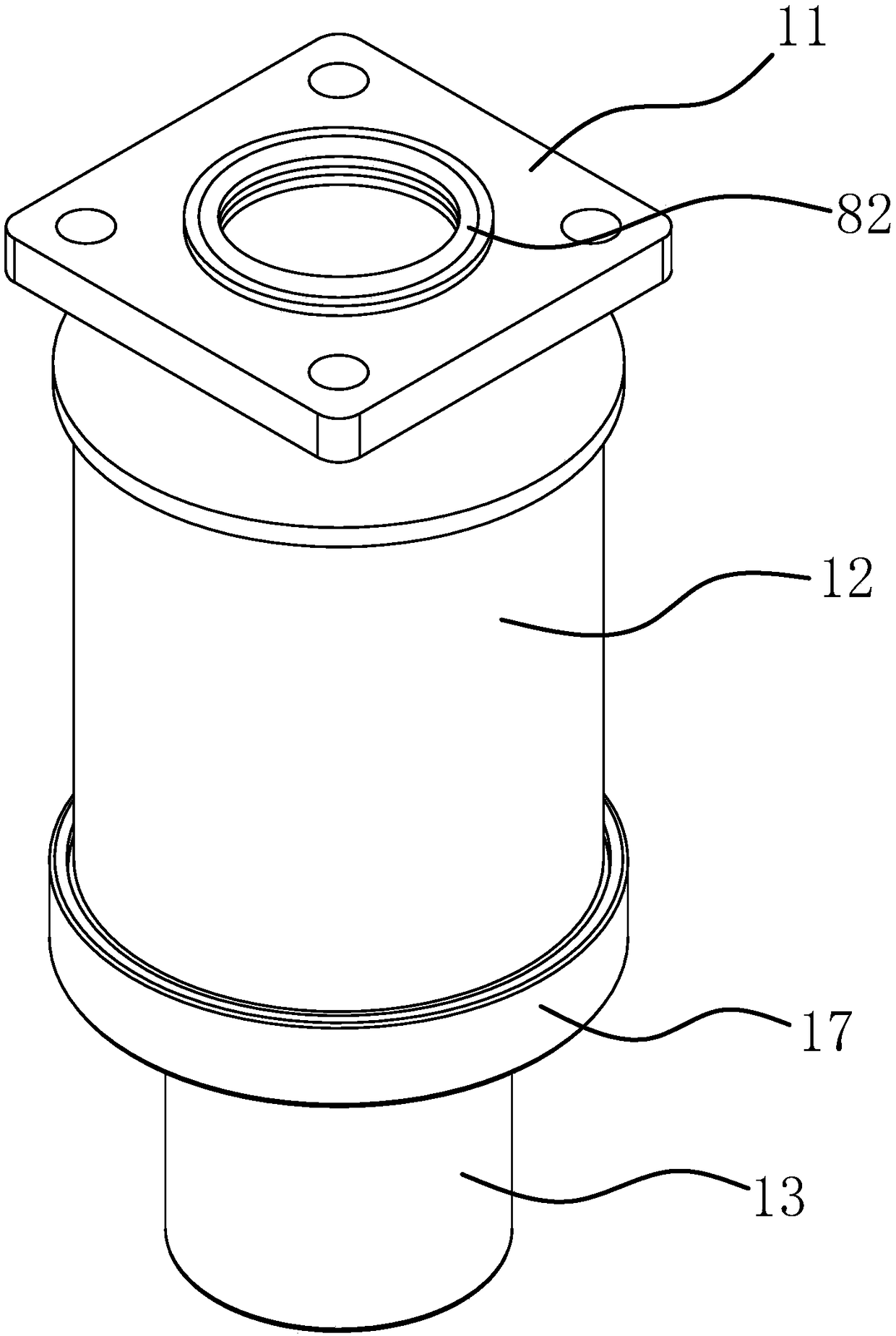

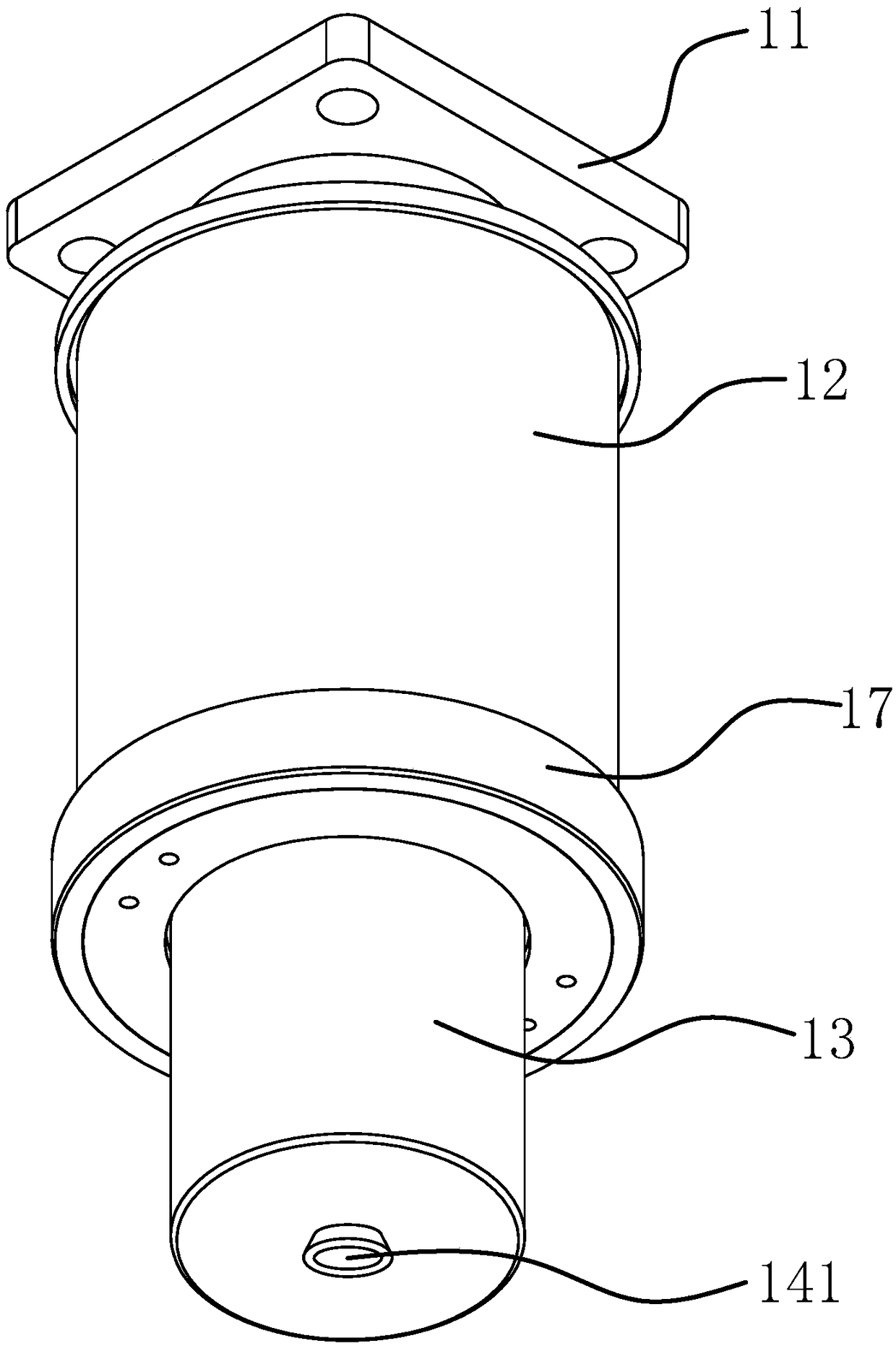

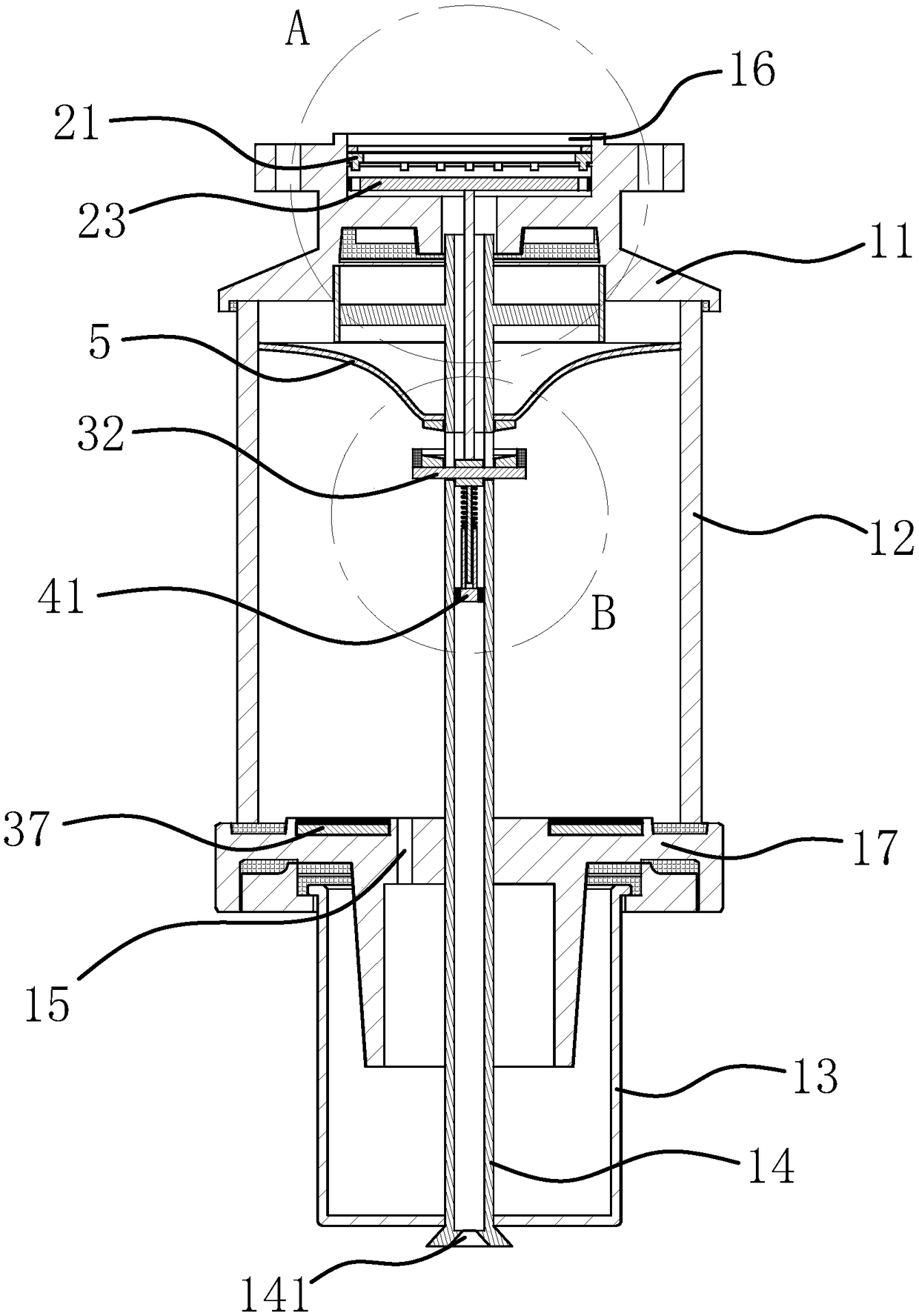

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the respirator includes a connecting flange 11, a silicone cover 12, an oil cup 13, and a breathing tube 14. The upper and lower ends of the breathing tube 14 are connected to the connecting flange 11 and the oil cup 13, respectively, and the upper end of the silicone cover 12 is connected to The flanges 11 are sealed and connected, the lower end of the silicone cover 12 is connected to the oil cup 13 through a mounting seat 17, and the mounting seat 17 is sealed to the oil cup 13 and the silicone cover 12; the mounting seat 17 is provided with a communicating oil cup 13 And the oil through hole 15 in the inner cavity of the silicone cover 12; the silicone cov

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap