Built-in water box type liquid food or beverage self-heating cup

A water box type, self-heating cup technology, applied in the direction of packaged food, food heating containers, types of packaged items, etc., can solve the problems of high cost, difficult processing, inconvenient life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

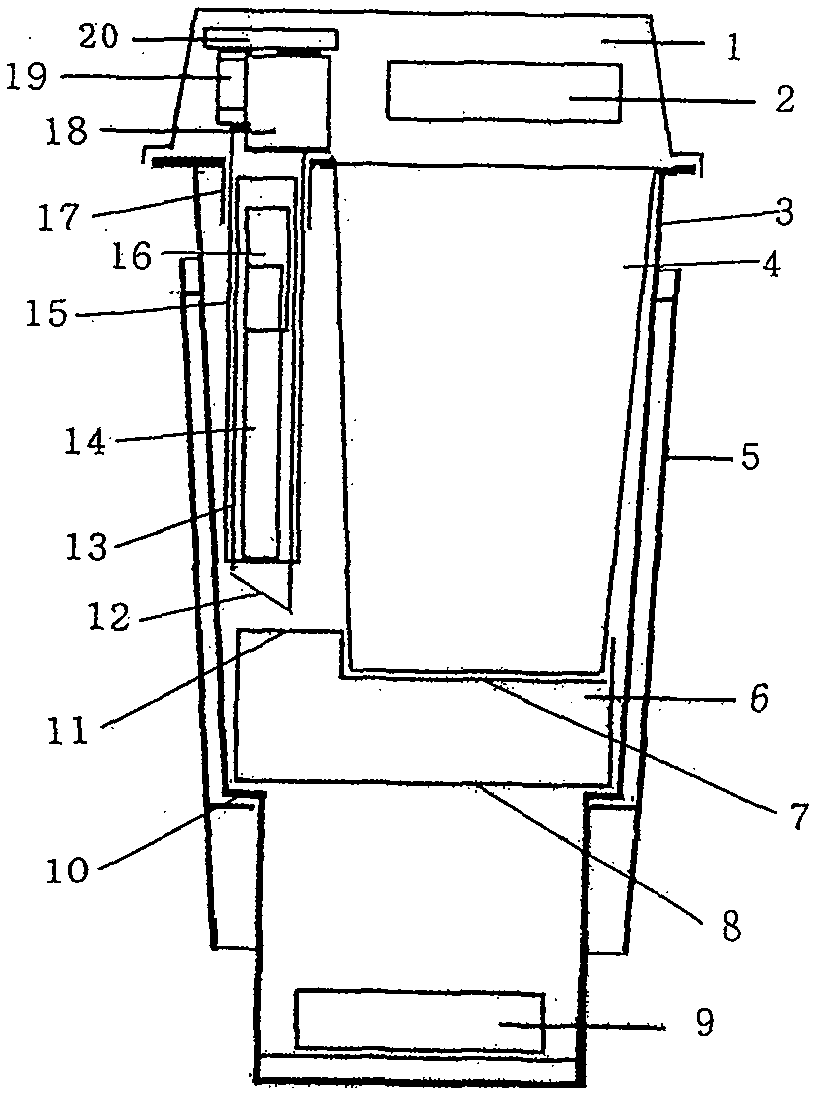

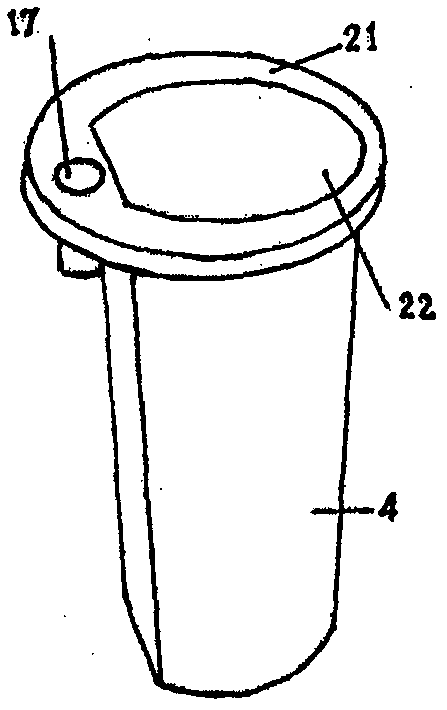

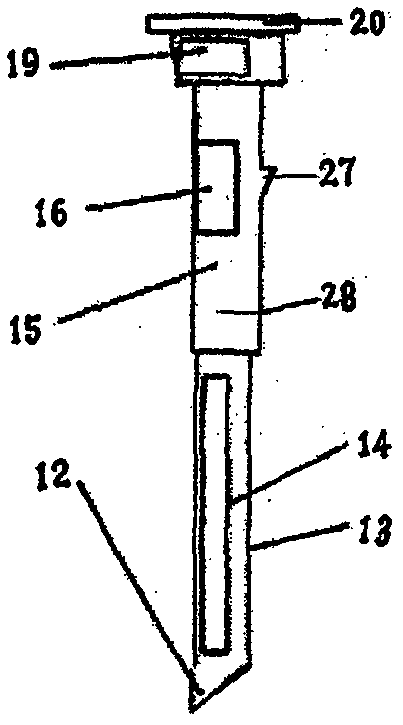

[0016] Embodiment 1 sees: figure 1 , figure 2 , image 3 , Figure 5 , Figure 8

[0017] The pp plastic conical cup 3 has an outer top cover 1, a straw or a small spoon 2 is installed inside the outer top cover 1, an anti-scalding cover 5 is provided outside the cup, and an annular step 10 with a steam-permeable groove is arranged on the lower part of the cup, and the step 10 A heating water box 6 with heating water is placed on it, the bottom of the heating water box 6 is closed by a film 8, and the water box cover plate has a film starting hole 11 and a circular shape with a flat section. Or oval groove 7, heating pack 9 is placed at the bottom of cup 3, and the flanging on the cup cover 21 and the flanging on the cup mouth are fastened to close the cup body. There are two orifices, one large and one small, on the cup cover 21. The large orifice 22 is injection-molded to connect a liner 4 for adorning liquid food or beverage. The liner 4 is a conical or elliptical conica

Embodiment 2

[0018] Embodiment 2 sees: figure 1 , Figure 7 , Figure 9 , Figure 8

[0019] Remove the annular step 10 supporting the heating water box 6 in Example 1, and put the heating water box 6 in the cup instead Figure 7 , Figure 9 The shown independent bracket support, the cup body and the anti-scalding cover on the outside of the cup are changed to a paper cup body and cup cover, and the rest are the same as in Embodiment 1.

Embodiment 3

[0020] Example 3 see figure 1 , Figure 4 , Figure 6 , Figure 7 , Figure 9

[0021] The starting stick in embodiment 1 is set as Figure 6 As shown in the one-piece structure that cannot be stretched or folded, the PP material cup body 3 is changed to Figure 4 As shown in the cup body, a starting rod installation card slot 24 is arranged on the side of the cup body adjacent to the starting hole 17 of the cup cover, and an opening 23 is added on the side of the cup cover 21 adjacent to the starting hole 17, and the starting rod is installed on the card outside the cup body. In the groove 24, at the same time, the opening 11 side of the heating water box is correspondingly set and adjusted at the card groove 24 of the outer cup to achieve internal and external matching, and the rest are the same as in embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap