Method for inhibiting noise of downwind type wind generator set based on variable-helical-angle groove

A technology of variable helix angle and noise suppression, which is applied to the installation/support of wind turbine configuration, wind power generation, mechanical equipment, etc., can solve the problems of increased equipment cost, equipment failure, large energy input, unsuitable use, etc., to achieve reduction The noise effect is remarkable, the effect is convenient to realize, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

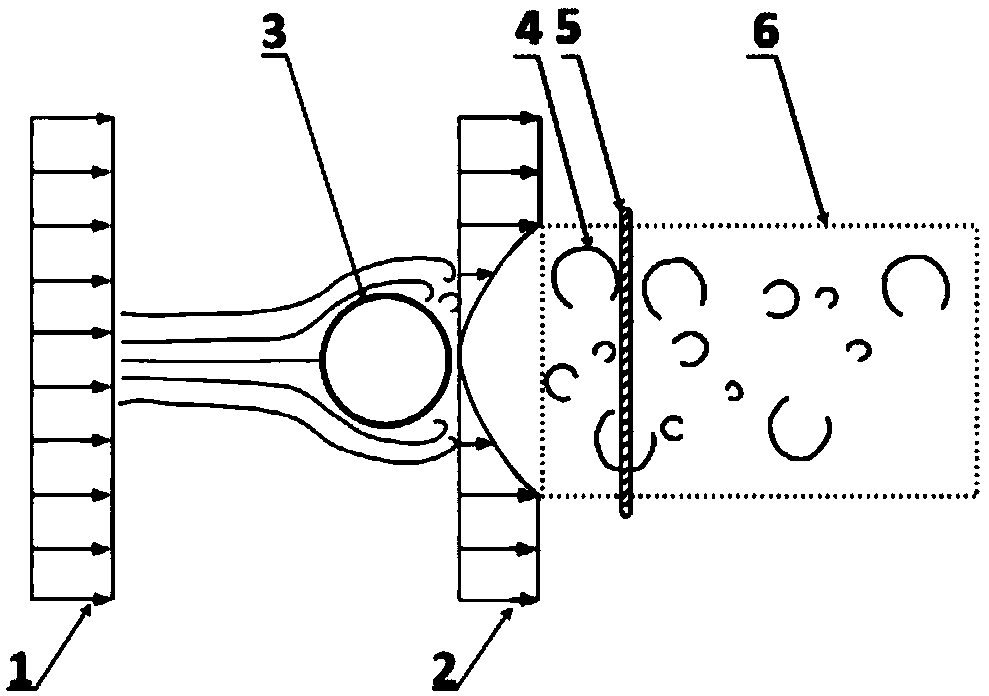

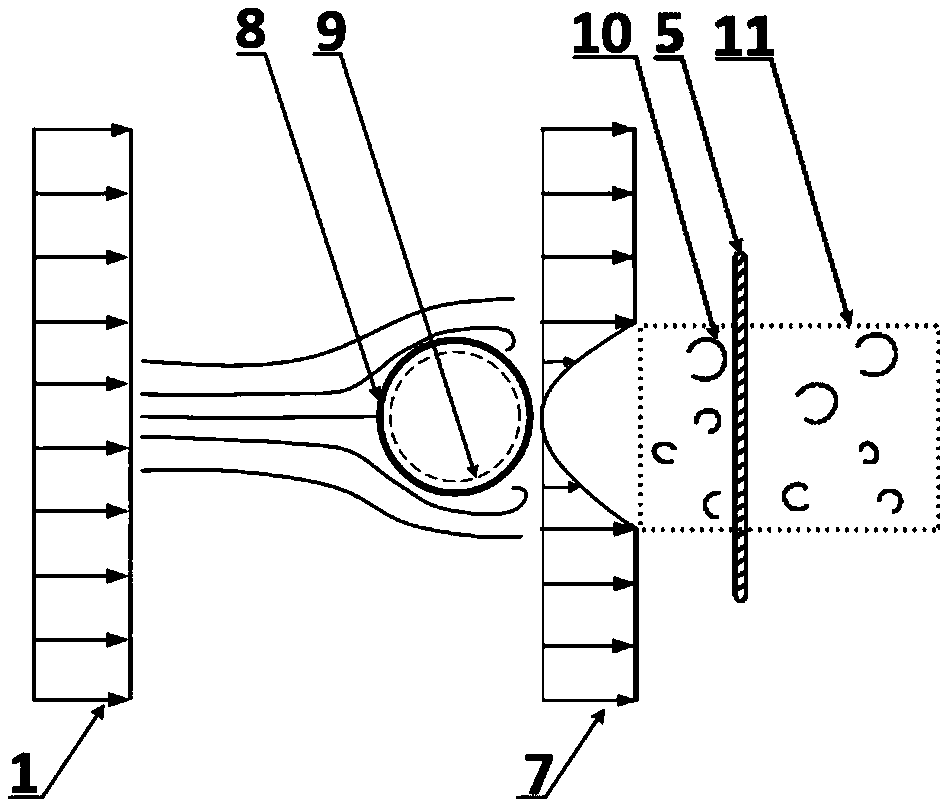

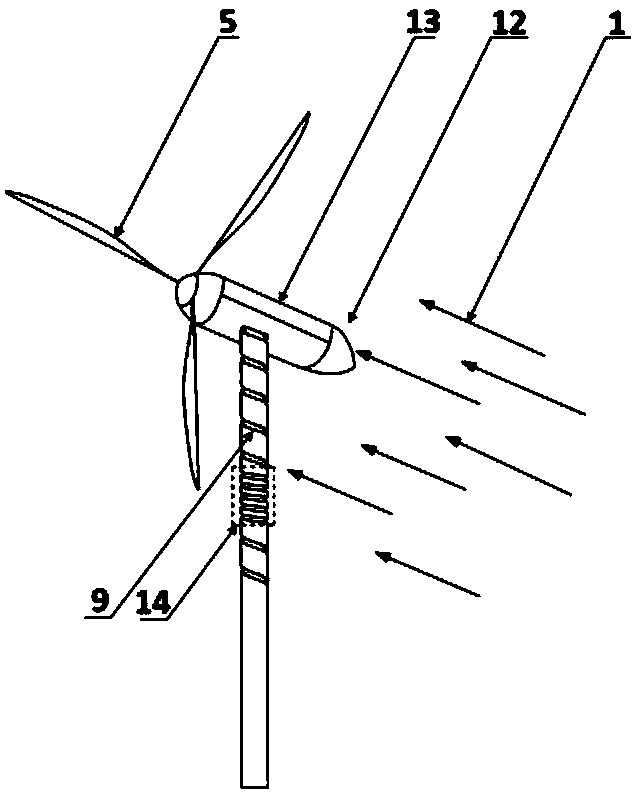

[0035] figure 1 Represents the principle of the tower shadow effect of the downwind wind turbine: when the infinite horizontal incoming flow 1 flows through the downwind wind turbine, the airflow near the cylindrical tower is blocked by the downwind wind turbine cylindrical tower 3, forming a Tathagata flow passing through Speed loss after cylindrical tower 2. The size and vector direction of the airflow blocked by the tower will change, and the vortex 4 that flows through the tower and falls off is formed on both sides of the cylindrical tower. The wake area of the tower will generate unsteady Karman vortex street, forming the velocity deficit area6 after the incoming flow passes through the tower. The unsteady wake area of the tower flows through the blades 5 of the wind turbine, and the vortex 4 shed from the incoming flow passing through the tower interacts with the blades to cause load fluctuations on the surface of the blades and generate low-frequency noise. figur

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap