Combined-cabinet

A combined cabinet and side panel technology, which is applied to cabinets, detachable cabinets, door leaves, etc., can solve the problems of single design structure, complex design of combined cabinets, monotonous forms, etc., and achieves simplified production process, easy disassembly, and remarkable technology effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

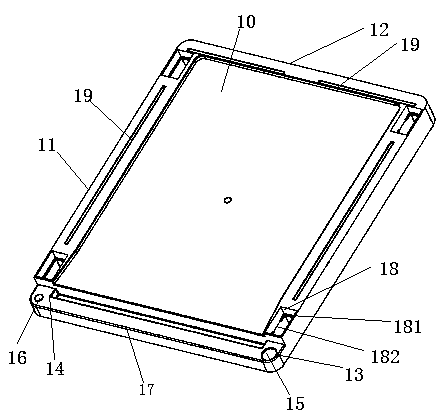

[0070] like Figure 1-25 The combination cabinet shown includes a middle panel 1 , a rear panel 2 , a side panel 3 , a top panel 4 and a door panel 5 .

[0071] The middle plate 1 includes a middle plate body 10, a middle plate side 11 and a middle plate rear 12 arranged around the middle plate body 10, the middle plate side 11 is divided into a middle plate left side and a middle plate right side, and the middle plate The height of the board body 10 is lower than that of the sides 11 of the middle board and the rear side 12 of the middle board. The middle board body 10 is used to separate the storage space and can be used to carry objects to be stored.

[0072] The middle board 1 is divided into front and back, the front is as follows figure 1 As shown, the back as figure 2 As shown, a first boss 13 is provided on the right side of the front end of the middle plate 1, and a first installation part 15 is provided on the first boss 13, and the first installation part 15 may pre

Embodiment 2

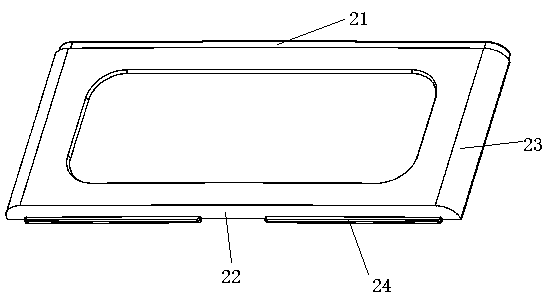

[0098] In this embodiment, the door panel is improved on the basis of Embodiment 1, and a layer panel 5 is added.

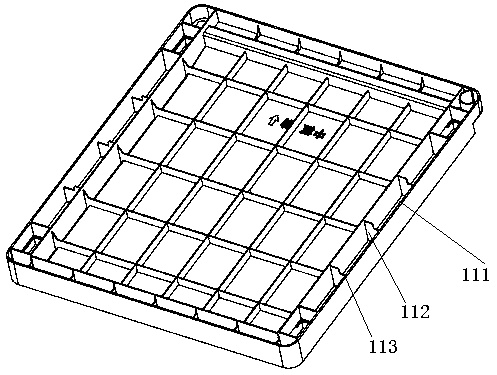

[0099] like Figure 13 , 14 As shown, the combination cabinet also includes a layer board 6, and the structure of the layer plate 6 is the same as that of the middle plate in Example 1, except that the first boss 13 and the second boss are subtracted from the plate in Example 1. Features of the table 14 , the first mounting portion 15 , the middle plate positioning portion 16 , and the connecting bar 17 .

[0100] Specifically, the laminate 6 includes a laminate body 60, a laminate side 61 and a laminate rear 62 arranged around the laminate body 60, and the laminate side 61 is divided into a left side of the laminate and a right side of the laminate On the side, the height of the board body 60 is lower than the height of the side edge 61 of the board and the height of the rear edge 62 of the board. The board body 60 is arranged between the upper and lower side boa

Embodiment 3

[0111] This embodiment improves the laminate on the basis of Embodiment 2.

[0112] like Figure 15 , 16 As shown, the laminate of this embodiment is based on Embodiment 2, except that the laminate body 60 is removed, so that the side 61 of the laminate and the rear edge 62 of the laminate form a U-shaped structure.

[0113] This structural arrangement can connect the multi-layer space between the middle plate 1 and the top plate up and down, so as to form a space long enough to meet the needs of different objects.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap