Reusable thermal transfer printing colored tape and preparation method thereof

A technology of thermal transfer ribbon and color layer, applied in printing, ink ribbon, inking device, etc., can solve the problem of high use cost, achieve the effect of reducing use cost, large economic and environmental benefits, and reducing waste generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1

[0022] A thermal transfer ribbon that can be used twice is composed of a tape base and a high-temperature color layer and a low-temperature color layer coated on the tape base in sequence.

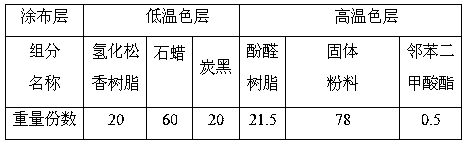

[0023] The types and parts by weight of raw materials used in the high-temperature chromatography and low-temperature chromatography are shown in the following table. Among them, the selected hydrogenated rosin resin has a softening point of 90°C, a melting point of paraffin wax of 60°C, and a softening point of phenolic resin of 110°C.

[0024]

[0025] The preparation method of the above-mentioned reusable thermal transfer ribbon comprises the following steps:

[0026] a) Take each raw material in proportion, dissolve the phenolic resin with a mixed solvent composed of toluene and methyl ethyl ketone at a volume of 1:1 (the amount of the mixed solvent is 7 times the weight of the phenolic resin) to obtain a resin solution, and mix the resin solution with phthalo Este

Example Embodiment

[0028] Example 2

[0029] A thermal transfer ribbon that can be used twice is composed of a tape base and a high-temperature color layer and a low-temperature color layer coated on the tape base in sequence.

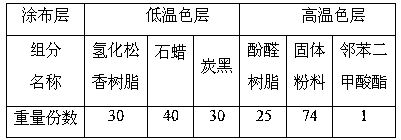

[0030] The types and parts by weight of raw materials used in the high-temperature chromatography and low-temperature chromatography are shown in the following table. Among them, the selected hydrogenated rosin resin has a softening point of 105°C, a melting point of paraffin wax of 55°C, and a softening point of phenolic resin of 120°C.

[0031]

[0032] The preparation method of the above-mentioned reusable thermal transfer ribbon comprises the following steps:

[0033] a) Take each raw material in proportion, dissolve the phenolic resin with a mixed solvent composed of toluene and methyl ethyl ketone at a volume of 1:1 (the amount of the mixed solvent is 7 times the weight of the phenolic resin) to obtain a resin solution, and mix the resin solution with phthalo Est

Example Embodiment

[0035] Example 3

[0036] A thermal transfer ribbon that can be used twice is composed of a tape base and a high-temperature color layer and a low-temperature color layer coated on the tape base in sequence.

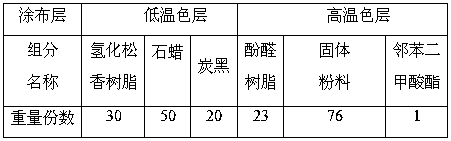

[0037] The types and parts by weight of raw materials used in the high-temperature chromatography and low-temperature chromatography are shown in the following table. Among them, the hydrogenated rosin resin selected has a softening point of 90°C, a melting point of paraffin wax of 65°C, and a softening point of phenolic resin of 100°C.

[0038]

[0039] The preparation method of the above-mentioned reusable thermal transfer ribbon comprises the following steps:

[0040] a) Take each raw material in proportion, dissolve the phenolic resin with a mixed solvent composed of toluene and methyl ethyl ketone at a volume of 1:1 (the amount of the mixed solvent is 7 times the weight of the phenolic resin) to obtain a resin solution, and mix the resin solution with phthalo Este

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap