Device for low-cost integrated treatment of high-concentration organic wastewater

A high-concentration technology for organic wastewater, applied in anaerobic digestion treatment, filtration treatment, multi-stage water treatment, etc., can solve the problems of large discharge, aggravation, and difficulty in meeting national standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0049] Example 1

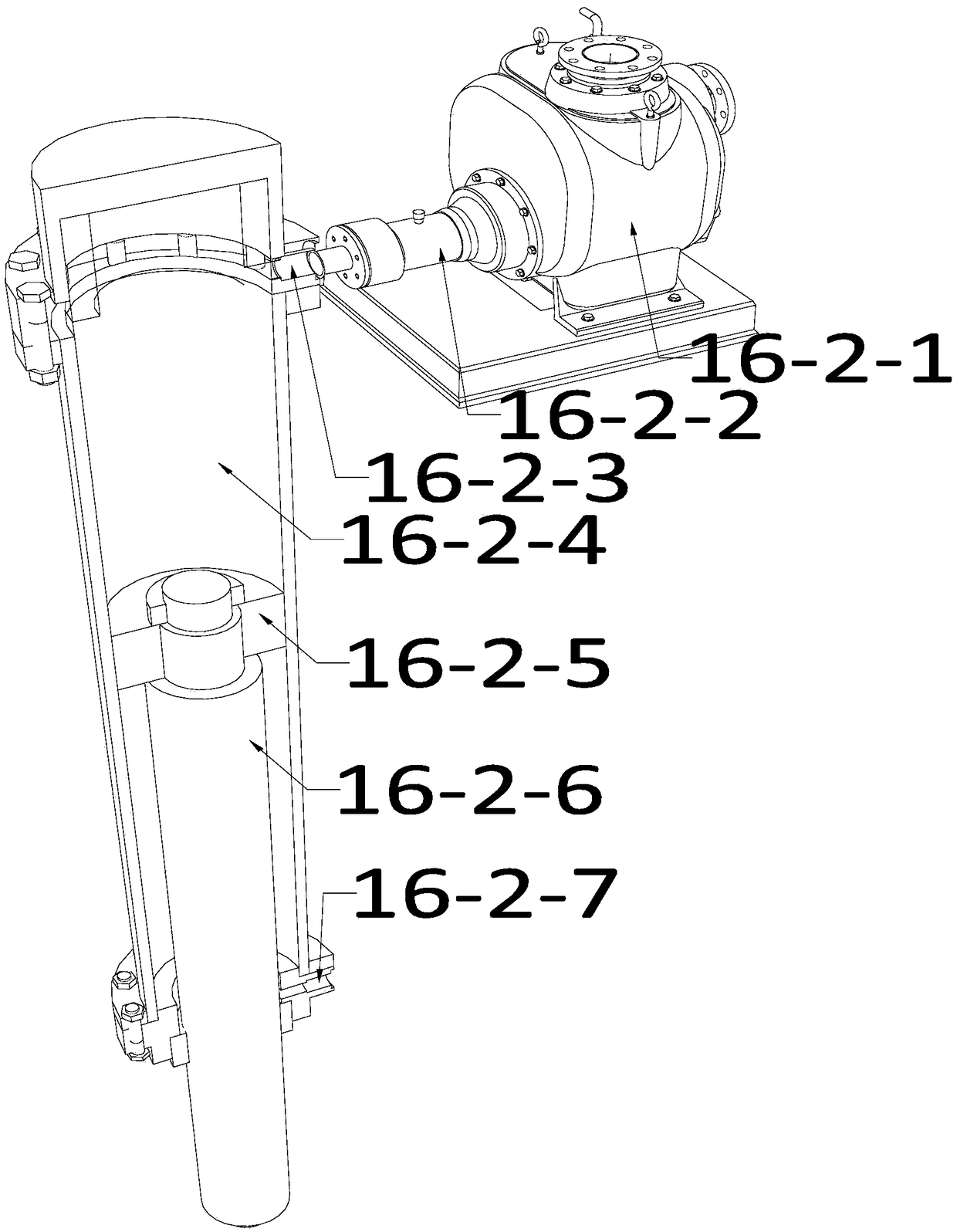

[0050] Manufacture the piston 16-2-5 of the present invention according to the following steps, and by mass percentage content:

[0051] Step 1: Add 22% ultrapure water with a conductivity of 1.25 μS / cm into the reaction kettle, start the agitator in the reaction kettle, the speed is 125 rpm, start the heating pump, and make the temperature in the reaction kettle rise to 75 ℃; Methyl ester derivatives 30%, mixing aids 1%, stir until completely dissolved, adjust pH to 5.5, add 25% phosphorothioate derivatives, adjust the stirrer speed to 255rpm, and the temperature to 90°C ;

[0052] Step 2: Add O-ethyl O-(4-methylthiophenyl) S-propyl dithiophosphate 15% to 45%, (T-4)-bis(diethyldithioamino) Formic acid-S, S') zinc 2% mixed well;

[0053] Step 3: Add 1% of cross-linking agent, stirrer rotation speed is 75rpm, temperature is 90℃, keep this state for 5 hours, discharge material, put it into the compression molding machine to make piston 16-2-5.

Example Embodiment

[0054] Example 2

[0055] Manufacture the piston 16-2-5 of the present invention according to the following steps, and by mass percentage content:

[0056] Step 1: Add 32% ultrapure water with a conductivity of 3.15 μS / cm into the reaction kettle, start the agitator in the reaction kettle, the speed is 375 rpm, start the heating pump, and make the temperature in the reaction kettle rise to 185 ℃; Methyl ester derivatives 65%, mixing aids 5%, stir until completely dissolved, adjust the pH to 8.5, add 60% phosphorothioate derivatives, adjust the stirrer speed to 315rpm, and the temperature to 395℃ ;

[0057]Step 2: Add O-Ethyl O-(4-Methylthiophenyl)S-Propyl Dithiophosphate 45%, (T-4)-Bis(diethyldithiocarbamate-S ,S') Zinc 15% mixed evenly;

[0058] Step 3: Add 5% of cross-linking agent, stirrer rotation speed is 235rpm, temperature is 265℃, keep this state for 25 hours, discharge material, put it into compression molding machine to make piston 16-2-5.

Example Embodiment

[0059] Example 3

[0060] Manufacture the piston 16-2-5 of the present invention according to the following steps, and by mass percentage content:

[0061] Step 1: Add 29% ultrapure water with a conductivity of 1.315μS / cm into the reaction kettle, start the agitator in the reaction kettle, the speed is 178 rpm, start the heating pump, and make the temperature in the reaction kettle rise to 85 ℃; Methyl ester derivatives 39%, mixing aids 4%, stir until completely dissolved, adjust the pH to 5.8, add 40% phosphorothioate derivatives, adjust the speed of the stirrer to 300rpm, and the temperature to 90°C ;

[0062] Step 2: Add O-ethyl O-(4-methylthiophenyl)S-propyl dithiophosphate 40%, (T-4)-bis(diethyldithiocarbamate-S ,S') Zinc 10% mixed evenly;

[0063] Step 3: Add 3% of cross-linking agent, stirrer rotation speed is 90rpm, temperature is 91℃, keep this state for 8 hours, discharge material, and put it into the compression molding machine to make piston 16-2-5.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap