Horizontal moving cylindrical shaft head turning equipment

A technology of horizontal movement and head turning, which is applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of complicated movement and positioning operations, difficult disassembly and replacement of turning heads, and difficulty in ensuring accurate position, so as to improve construction efficiency. and construction accuracy, improve construction efficiency, quality and efficiency, and facilitate the effect of fast and accurate movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

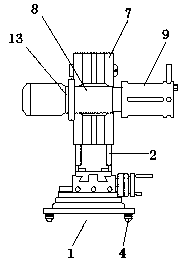

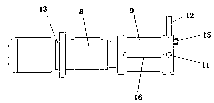

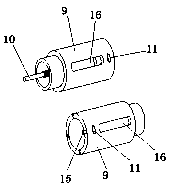

[0033] Example. Horizontal movement of external spindle turning equipment such as Figure 1 to Figure 13 As shown, it includes a mobile base device 1, a guide rail is provided below the mobile base device 1, and a column 2 is provided above the mobile base device 1. The mobile base device 1 includes a base plate 3, and an electromagnet is provided at the center of the bottom of the base plate 3. , the four corners below the base plate 3 are provided with a group of ball screws 4, and the setting positions of the ball screws 4 are aligned with the guide rails; the top of the base plate 3 is provided with a positioning installation turntable 5, and the top of the positioning installation turntable 5 is provided with a rotary knife feed seat 6; the positioning installation Bolt grooves are arranged in th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap