Method for electronically controlling pneumatic braking system in vehicle, and electronically controllable pneumatic braking system

A technology for pneumatic braking and commercial vehicles, which is applied to brake transmissions, brakes, vehicle components, etc., and can solve problems such as small average control pressure, reduced braking effect, and reduced service brake control pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

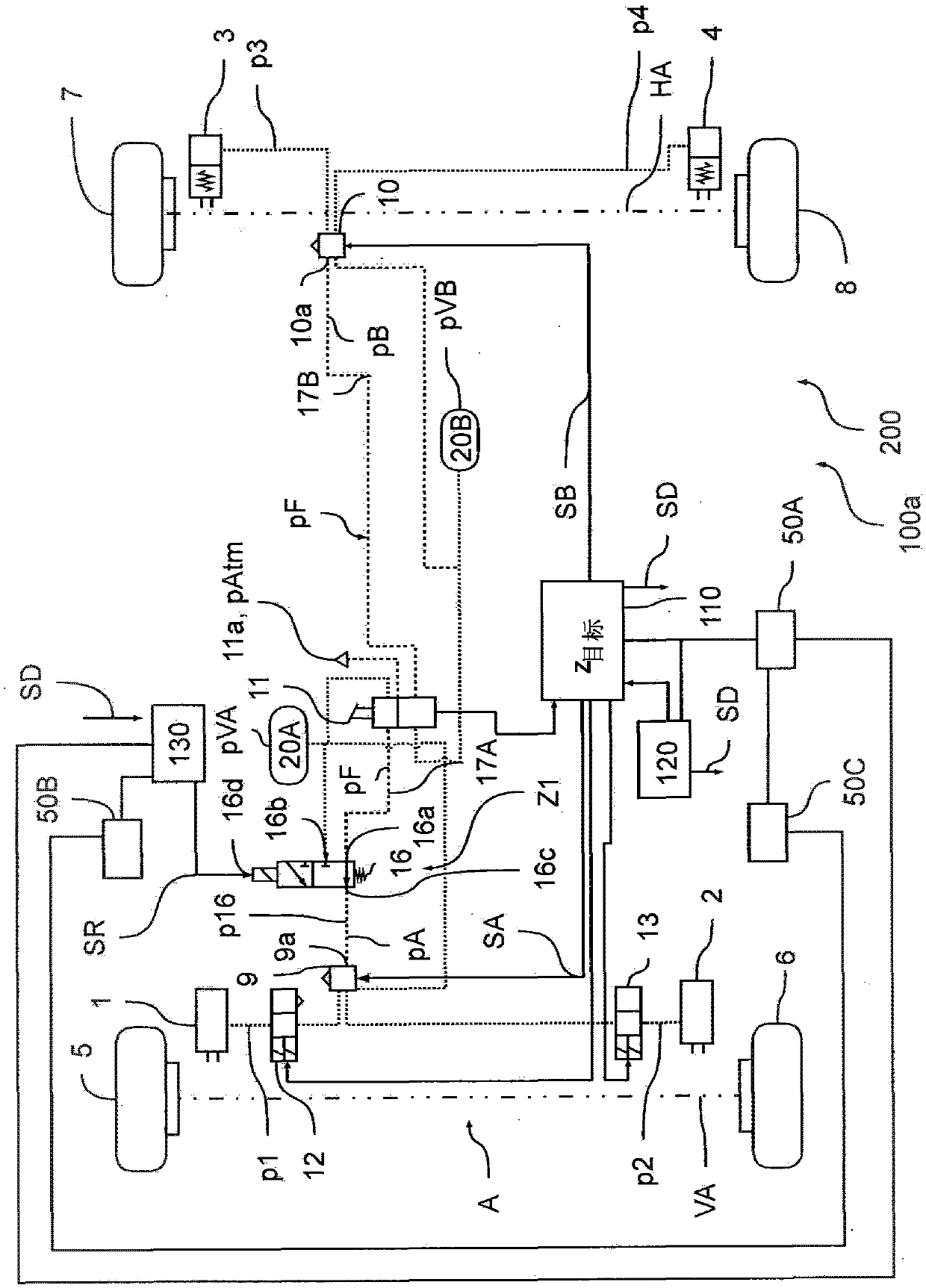

[0043] according to figure 1 A block diagram shows a section of an electro-pneumatic braking system 100a of a vehicle 200, especially a commercial vehicle, wherein the electro-pneumatic braking system is designed as an EBS braking system 100a, that is, it is implemented electrically in the normal driving mode Braking procedures. For this purpose, the EBS brake system 100a has a plurality of wheel brakes 1, 2, 3, 4, which are used to brake the vehicle 200. Two brake circuits A and B are provided for braking, and pressure medium reservoirs 20A and 20B are respectively assigned to them, so as to supply pressure medium to the respective brake circuits A and B and thus can realize the respective control of the vehicle 200 Construction of the service brake brake pressures p1, p2, p3, and p4 of the wheel brakes 1, 2, 3, and 4. There are corresponding reserve pressures pVA, pVB in each pressure medium reservoir 20A, 20B, wherein, in the first and second pressure medium reservoirs 20A, 20

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap