Protective film pasting equipment for aluminum profile

A technology of protective film and aluminum profiles, applied in packaging and other directions, can solve the problems of surface damage of aluminum profiles, easily damaged protective film, easy scratches and oxidation discoloration on the surface, etc., and achieves the effect of convenient operation and easy movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

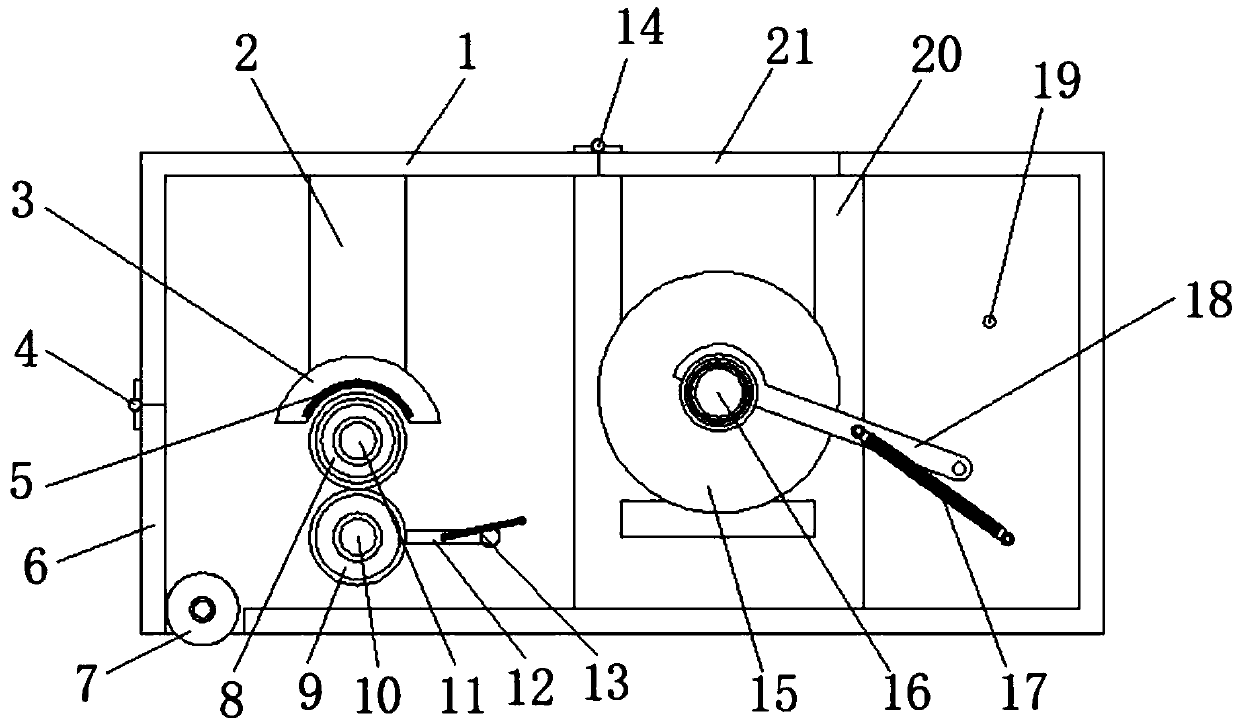

[0026] When in use, the film-coating cylinder is clamped by two fixed discs 15 and the positioning shaft 16, and then the two fixed discs 15 are fixed by the clamp 20, and then the clamping roller 9 is pressed downward to separate from the heat-sealing roller 8 , pull out the film through the gap, close the pinch roller 9, continue to pull the film to bypass the installation roller 7, then close the operation door 6 and the upper door 21, start the heating resistance wire 5 to heat the heat-sealing roller 8, pass the film The friction with the heat-sealing roller 8 and the pinch roller 9 drives the heat-sealing roller 8 to rotate to achieve continuous heating until the heated film is pulled out, and the mounting roller 7 is pressed on the surface of the aluminum profile for film coating operation.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap