Gas steaming oven

A steam box and gas technology, which is applied to steam cooking utensils, heating devices, etc., can solve problems such as safety accidents and users mistakenly turning on the gas switch, so as to reduce heat loss, improve preheating utilization, and improve compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

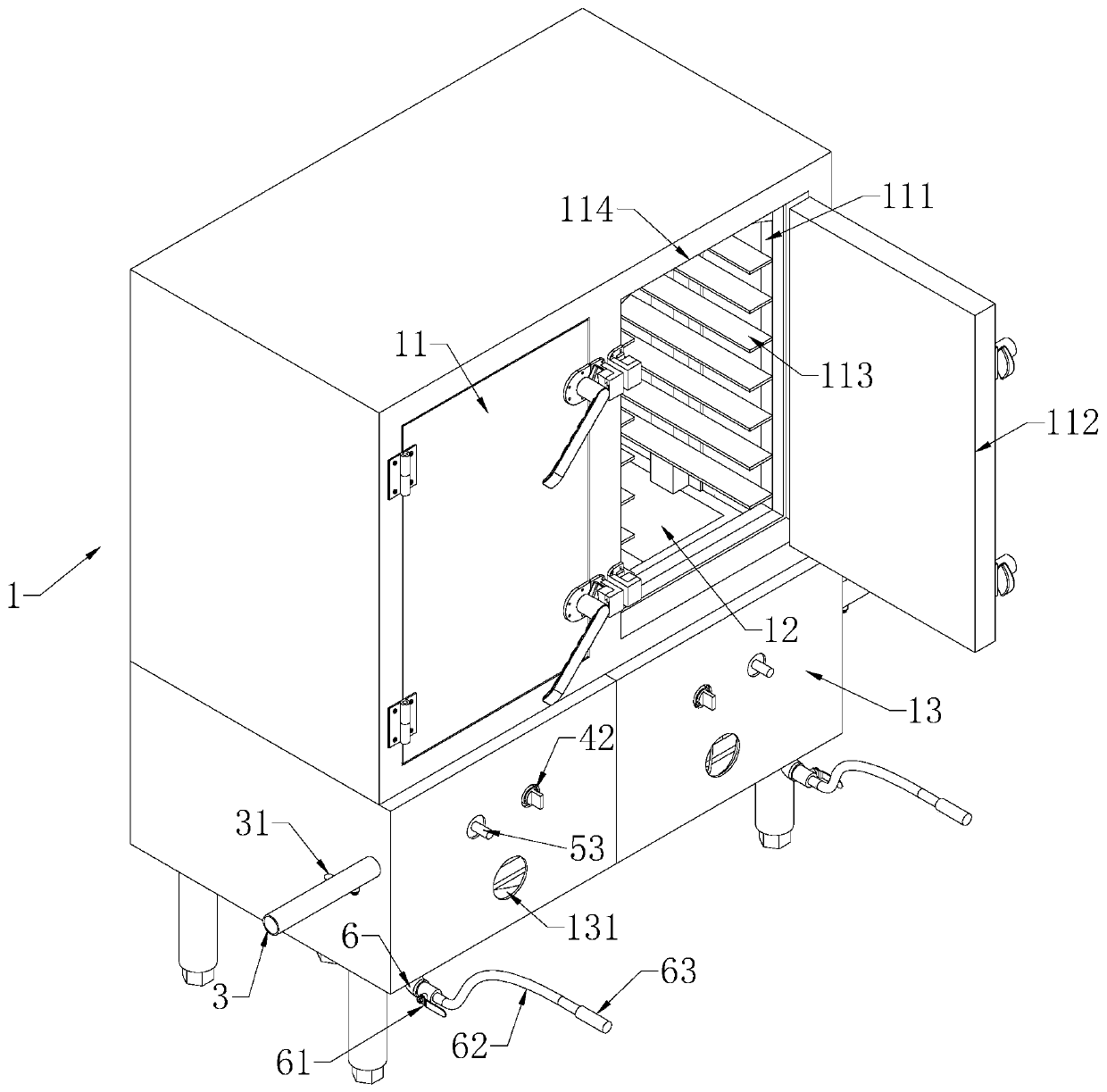

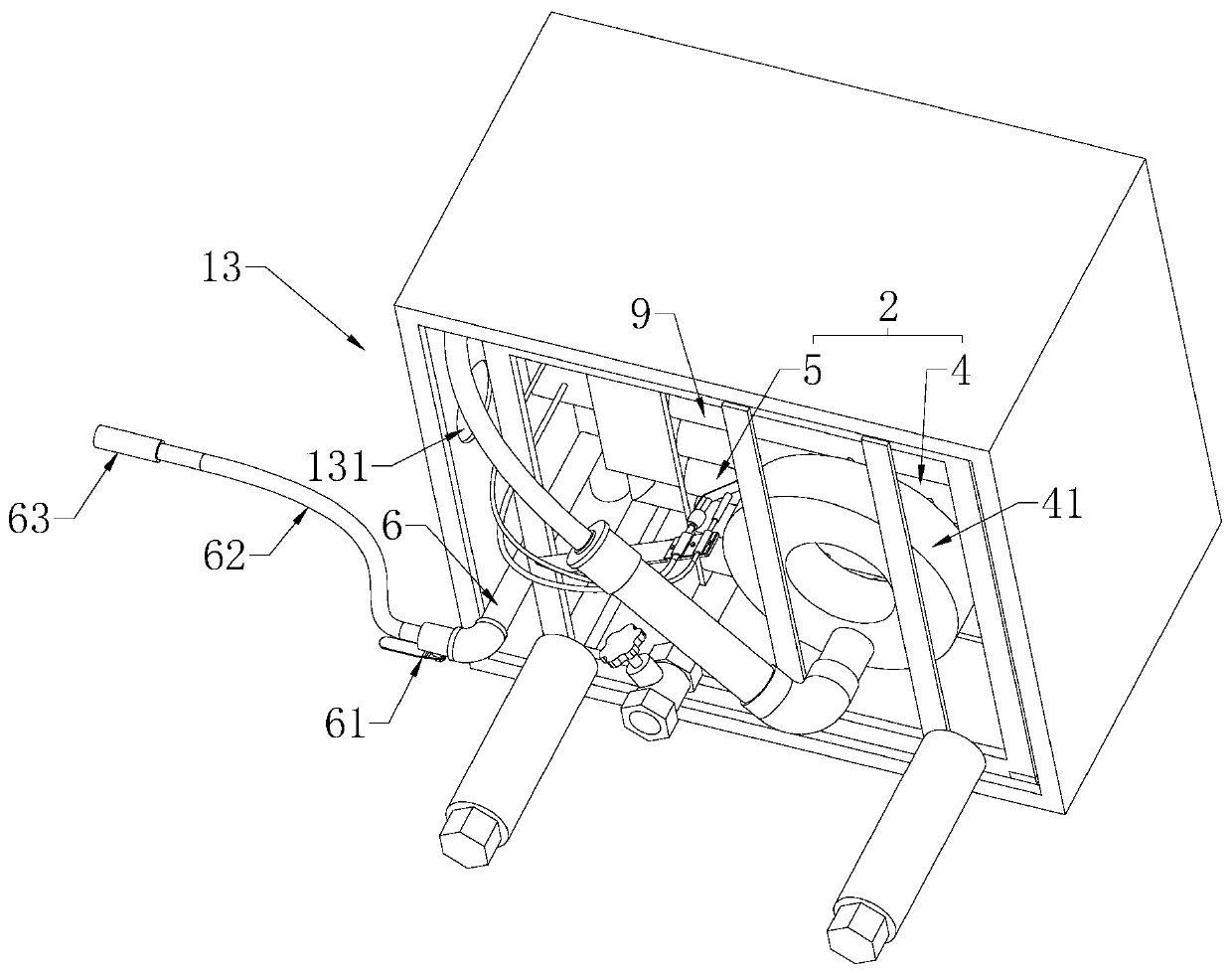

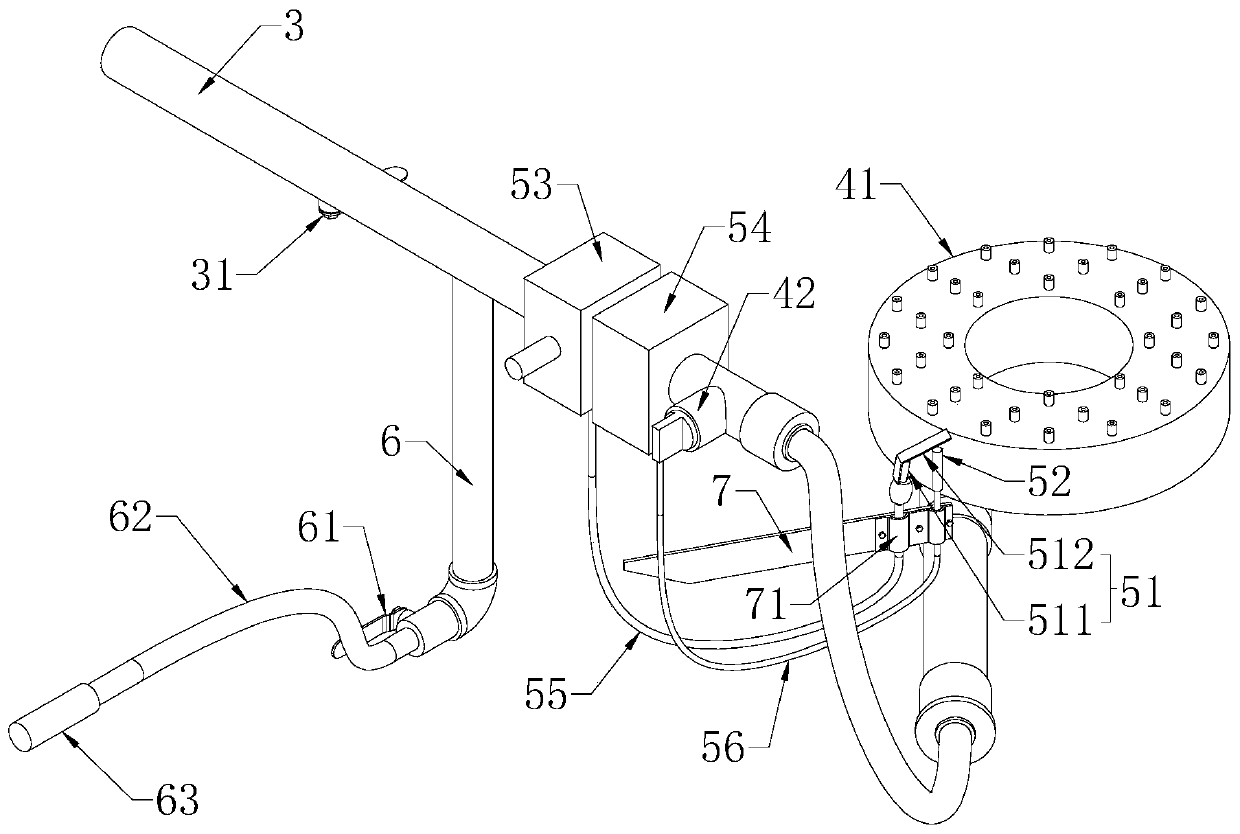

[0037] like figure 1 As shown, a gas steam box includes a box body 1. The box body 1 includes a steam chamber 11, a water tank room 12, and a combustion chamber 13 arranged vertically from top to bottom, and the box body 1 adopts a left-right symmetrical Design, that is, casing 1 includes left and right two groups of food steaming systems composed of steam chamber 11, water tank chamber 12 and combustion chamber 13. The steam chamber 11 includes a steam chamber 111 and a steam rack 113 fixed on the opposite inner walls of the steam chamber 111. The steam rack 113 is provided with a shelf for holding food, and the steam chamber 111 is located at the steam chamber opening on the front of the cabinet 1. A steam box door 112 is hinged at 114, and the steam box doors 112 of the two steam chambers 111 are arranged in opposite directions. The combustion chamber 13 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap