Plastic runway laying assisting tool

A technology of auxiliary tools and plastic track, which is applied in the direction of roads, pavements, roads, etc., and can solve the problems of increasing labor costs, wasting time, wasting time and effort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

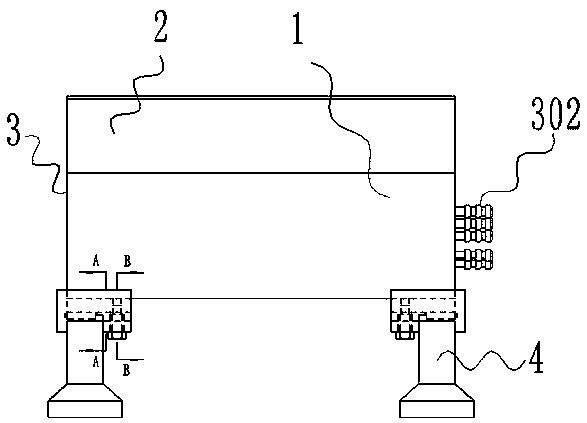

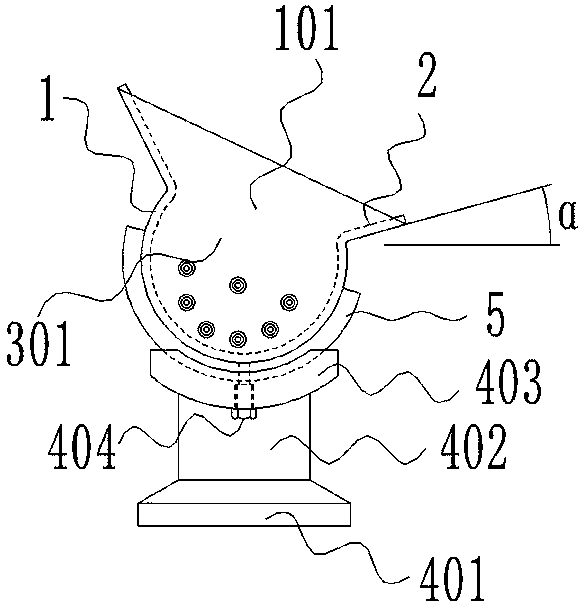

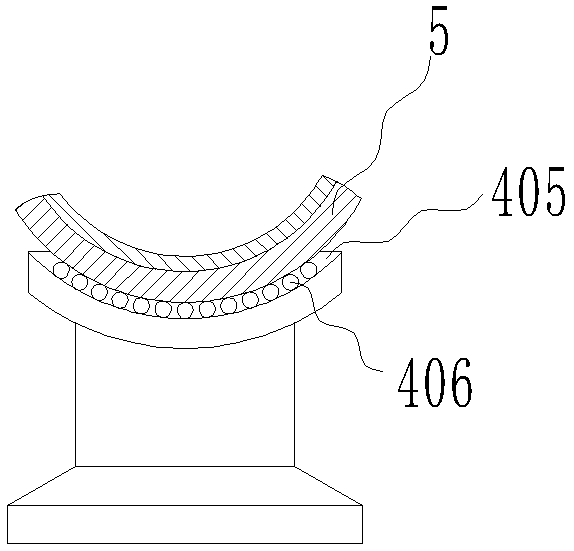

[0021] An auxiliary tool for laying a plastic runway includes a flow collecting tank 1 and a side plate 3, the upper part of the flow collecting tank 1 is provided with an opening 101, the two ends of the flow collecting tank 1 are connected with side plates 3, and the side plate 3 and the inner wall of the flow collecting tank 1 form a flow Manifold 301 connects the outlet of the spraying equipment to the flow manifold 1. When the viscous material fills the flow manifold 301, the viscous material will be sprayed from the opening 101. Mechanical components are used instead of manual operations to save labor At the same time, when the viscous material is ejected from the opening 101, it is uniformly ejected from the edge plane of the opening 101, thereby solving the problem of uneven viscous material in the transmission spraying operation, reducing the worki

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap