Road shoulder trimming die and trimming paver

A technology for trimming molds and road shoulders, which is applied in the field of road shoulder forming equipment, can solve the problems of damaged soil material layout, low equipment, hidden dangers to driver's life safety, etc., and achieve the effect of compact size and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings.

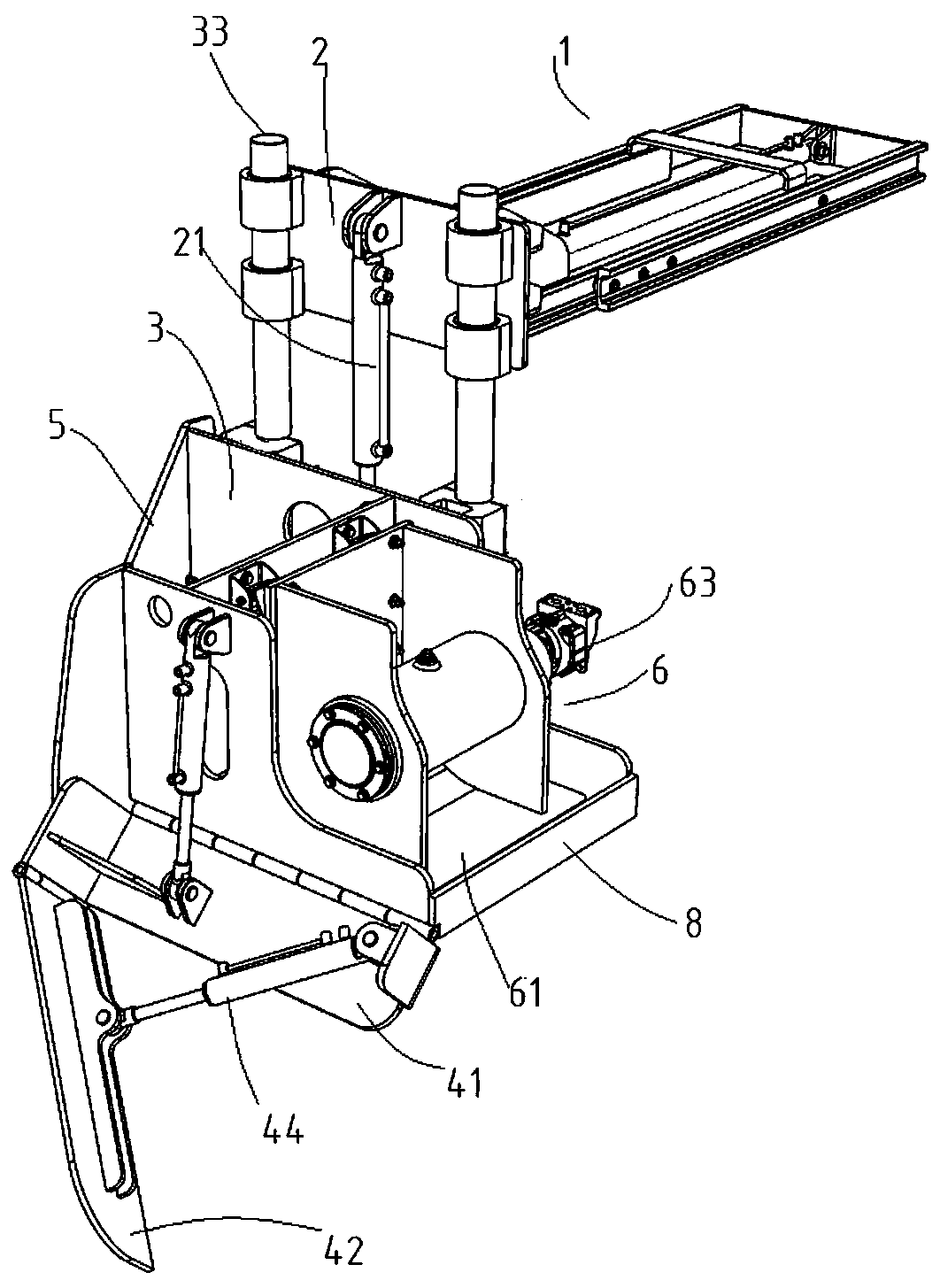

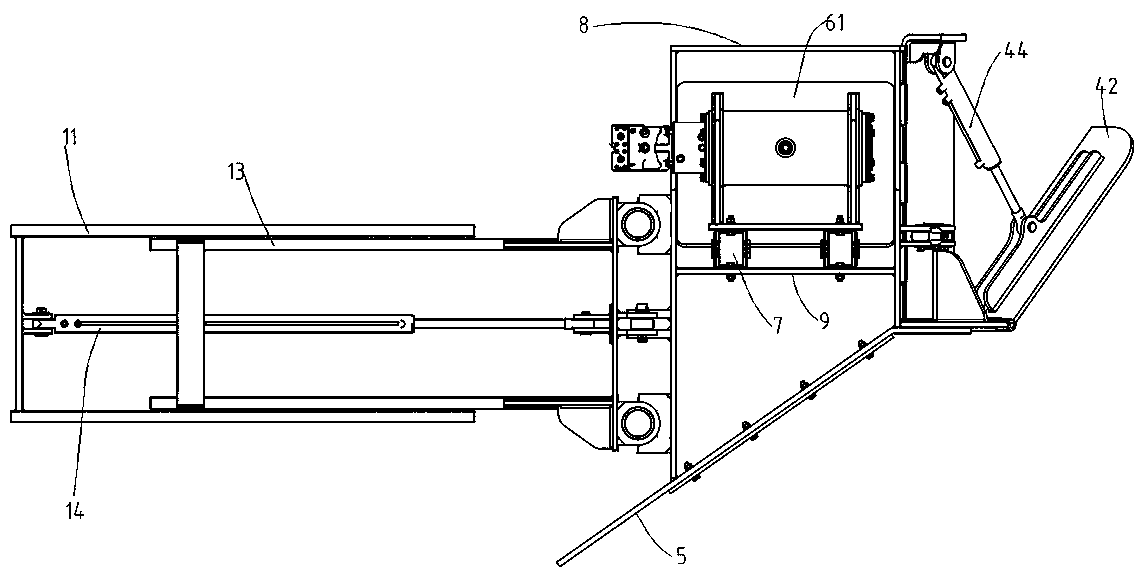

[0034] A road shoulder trimming die, comprising a forming die and a telescopic seat 1 that can drive the forming die to move left and right;

[0035] Described forming mold comprises left template 3, right template 4 and front guide plate 5, described left and right template 3,4 are arranged in parallel, and described front guide plate 5 is vertically welded on the front edge of left and right template 3,4 On, the lower part of the front guide plate 5 is provided with a feed port;

[0036] The telescoping seat 1 includes a fixed slideway 11, a moving slide rail 13 and a telescopic oil cylinder 14, one end of the moving slide rail 13 is connected to a forming die, and the other end is slidingly matched with the fixed slideway 11; the telescopic direction of the telescopic oil cylinder 14 Parallel to the sliding direction of the moving slide rail 13, one end of the telesco

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap