Multi-angle automatic grinding equipment for extruding shaft

A technology of extruding shafts and multi-angles, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of uneven discharge, large color difference of extruded materials, uneven product quality, etc., and achieve design Compact, simple in structure and low in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention will be further described below in conjunction with the embodiments in the drawings:

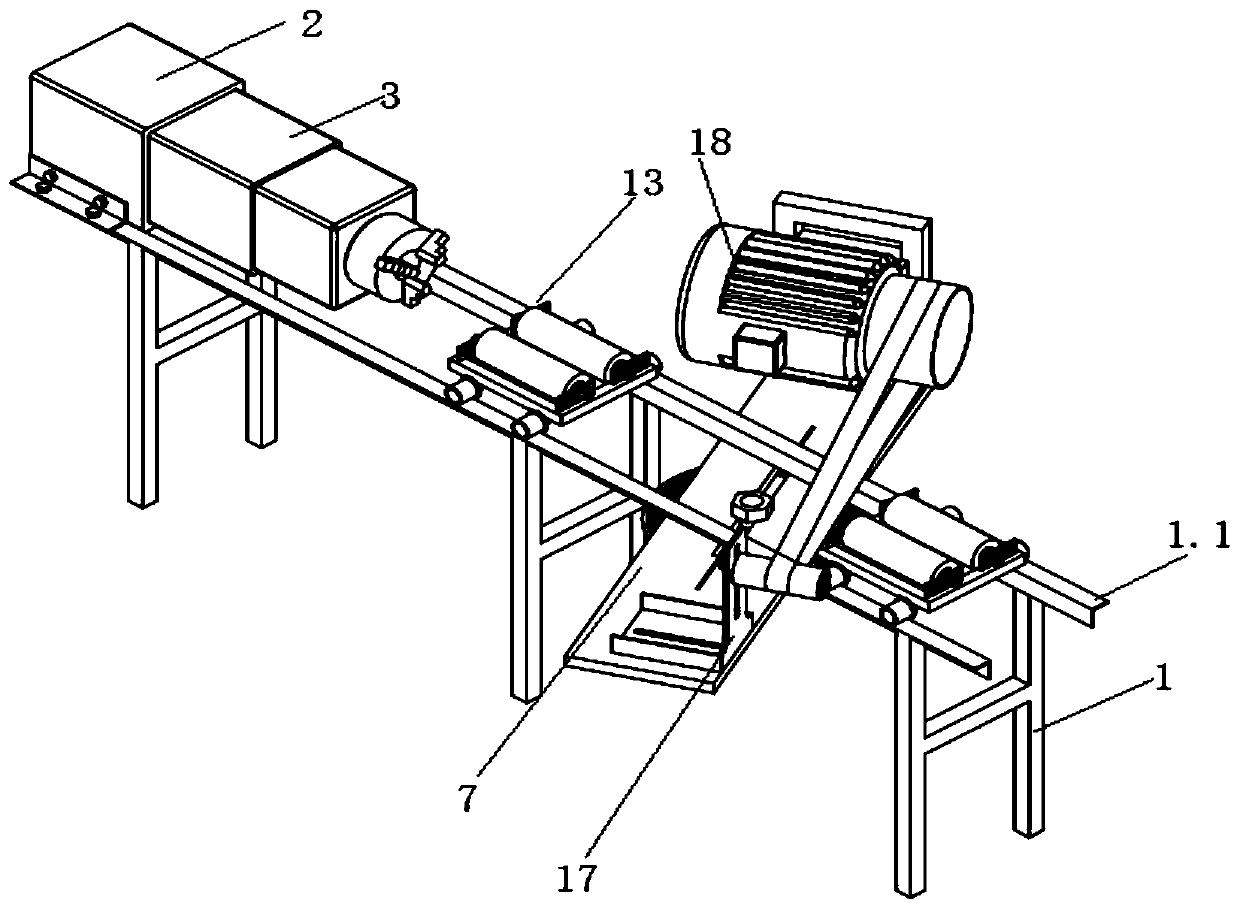

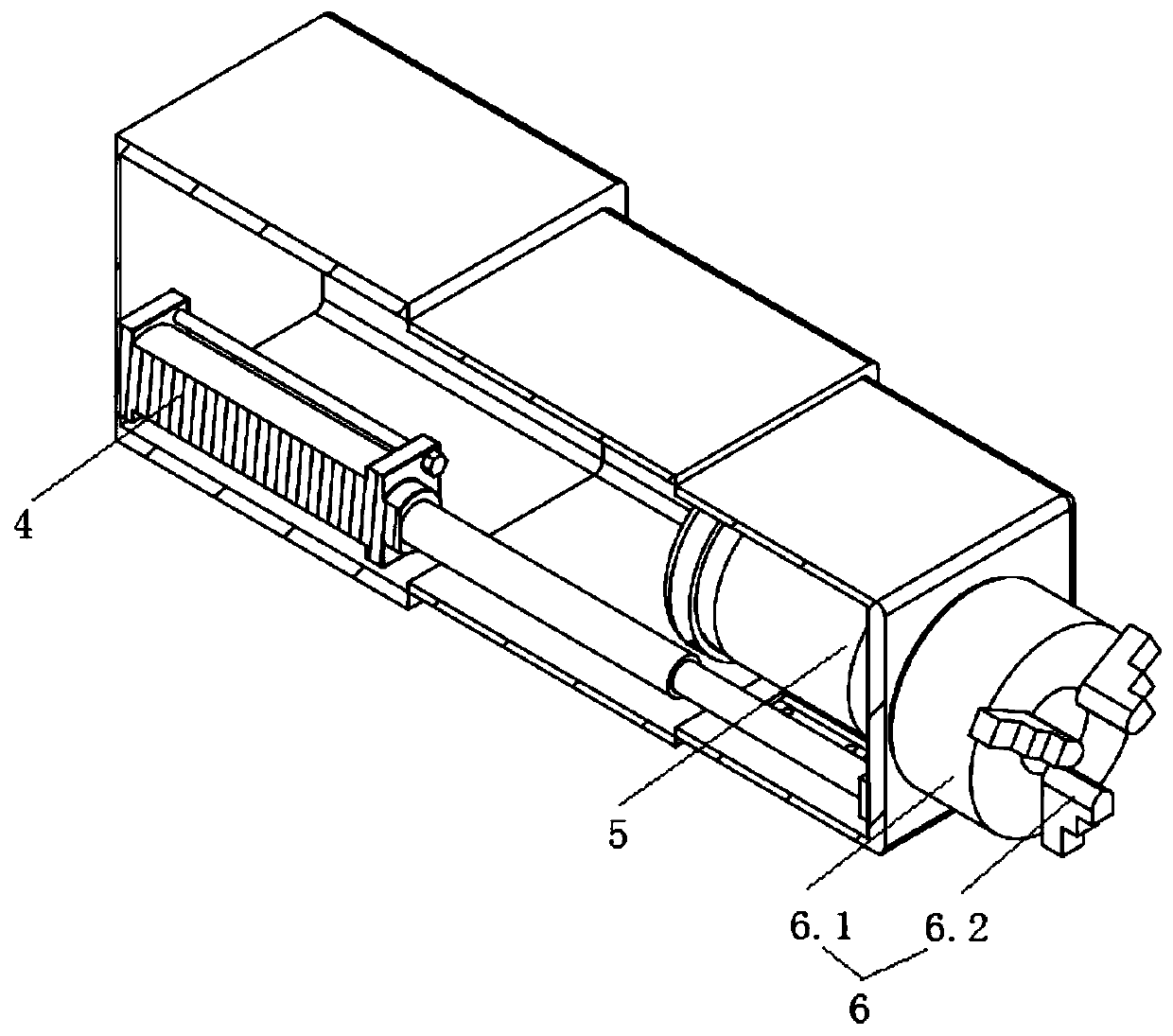

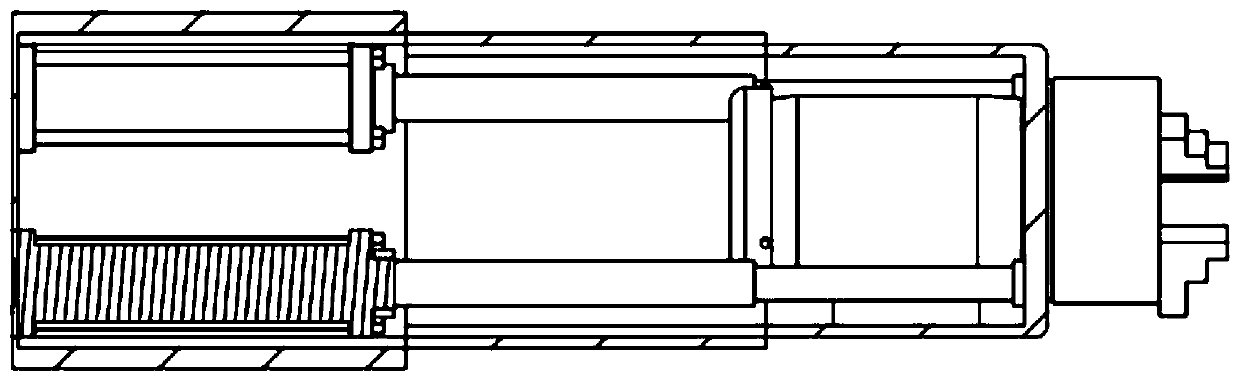

[0026] Such as Figure 1-6 As shown, in an embodiment of the present invention, a multi-angle automatic polishing extrusion shaft equipment is characterized in that the equipment includes an integral support 1, a hydraulic cylinder assembly, a tortoise cart 13, a polishing motor assembly and a circular dial;

[0027] The integral support 1 has multiple support legs. The top of the support is composed of a frame body 1.1. The top end of the support is provided with a hydraulic cylinder assembly; the integral support is welded by triangle steel and square pipes, and has a total of 6 legs, and the legs are welded by square pipes. The material used for the slide rail is triangular steel, which has a lower cost and is more suitable for production enterprises.

[0028] The hydraulic cylinder assembly includes a hydraulic cylinder barrel 2, a hydraulic cylinder plug 3, a hydraul

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap