Method and device for determining reliability of battery box of electric vehicle

A technology of electric vehicles and determination methods, applied in the field of automobiles, can solve the problems of lack of mature mechanism, aggravated battery inconsistency, affecting the reliability of battery boxes, etc., and achieve the effect of accurate reliability values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

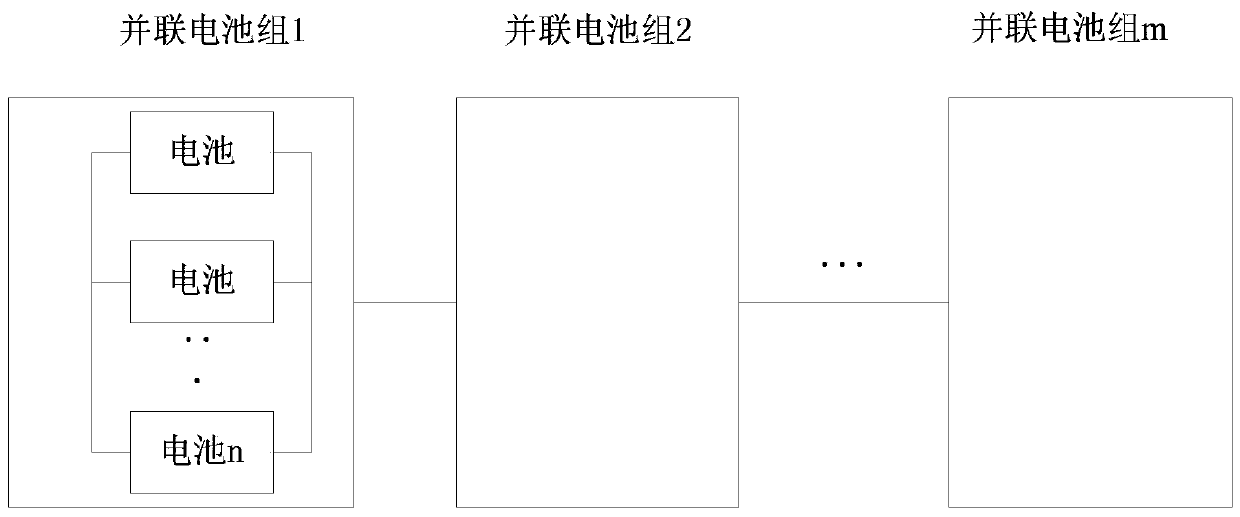

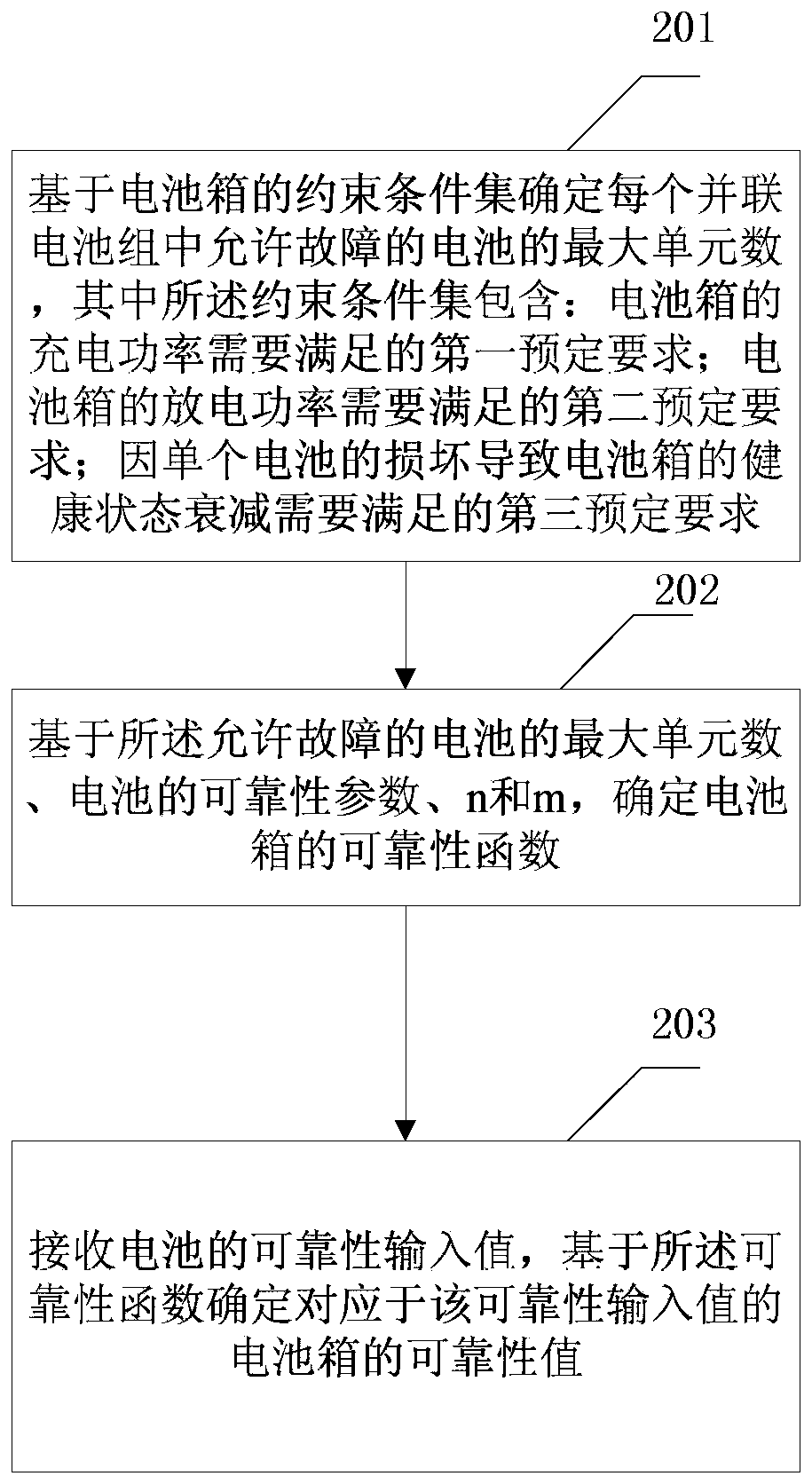

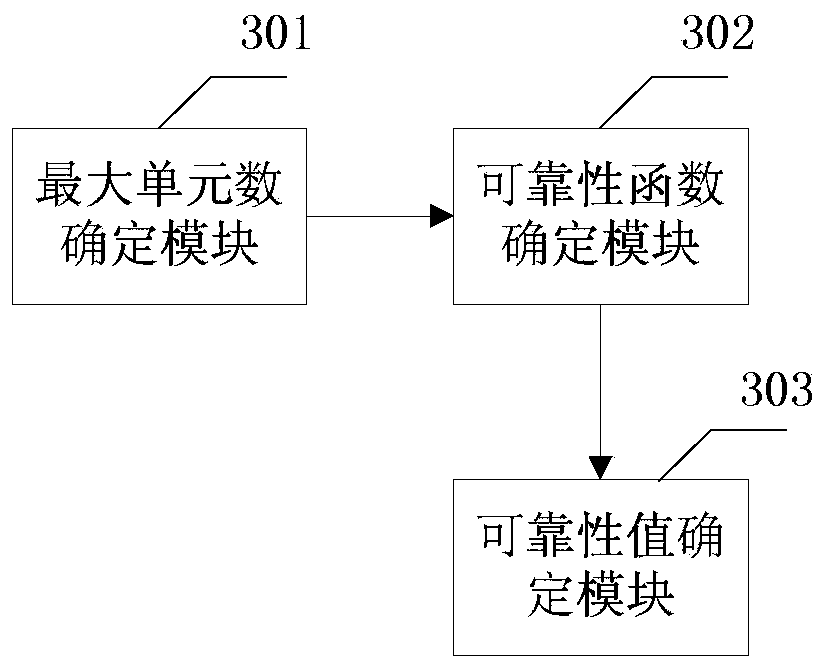

Method used

Image

Examples

example 1

[0063] The power battery system uses a nickel cobalt oxide lithium battery whose model is nCR18650. This type of lithium battery is a high-energy battery with a nominal voltage of 3.6V and a nominal capacity of 3.10Ah. The basic parameters of the power battery system are shown in Table 1-3, among which Table 1 is the basic parameter table; Table 2 is the cell power matrix table; Table 3 is the battery system power matrix table.

[0064] Cell model Panasonic Cell type Ternary Cell voltage / V3.60 Unit capacity / Ah3.10 Total battery voltage / V356.4 Total battery capacity / Ah213.90 Total battery power / kWh76.23 Group way 69P99S

[0065] Table 1

[0066] project parameter Remarks Sustainable charging current / A3.1 10s pulse charging current / A6.2 Continuous discharge current / A6.2 10s pulse discharge current / A9.2 Sustainable charging power / kW0.011 Sustainable discharge power / kW0.022

[0067] Table 2

[0068] project parameter Remarks Sustainable charging

example 2

[0085] The power battery system uses a nickel-cobalt-manganese lithium battery whose model is B18650CC. The battery has a nominal voltage of 3.60V and a nominal capacity of 2.00Ah. The basic parameters of the power battery system are shown in Table 4-6. Table 4 is the basic parameter table; Table 5 is the cell power matrix table; Table 6 is the battery system power matrix table.

[0086] Cell model CEA-LM36 Cell type Ternary Cell voltage / V3.65 Unit capacity / Ah36 Total battery voltage / V365 Total battery capacity / Ah218 Total battery power / kWh78.84 Group way 6P100S

[0087] Table 4

[0088] project parameter Remarks Sustainable charging current / A36 10s pulse charging current / A54 Continuous discharge current / A72 10s pulse discharge current / A108 Sustainable charging power / kW0.1314 Sustainable discharge power / kW0.2628

[0089] table 5

[0090] project parameter Remarks Sustainable charging current / A218 Pulse, step charging current / A327 Conti

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap