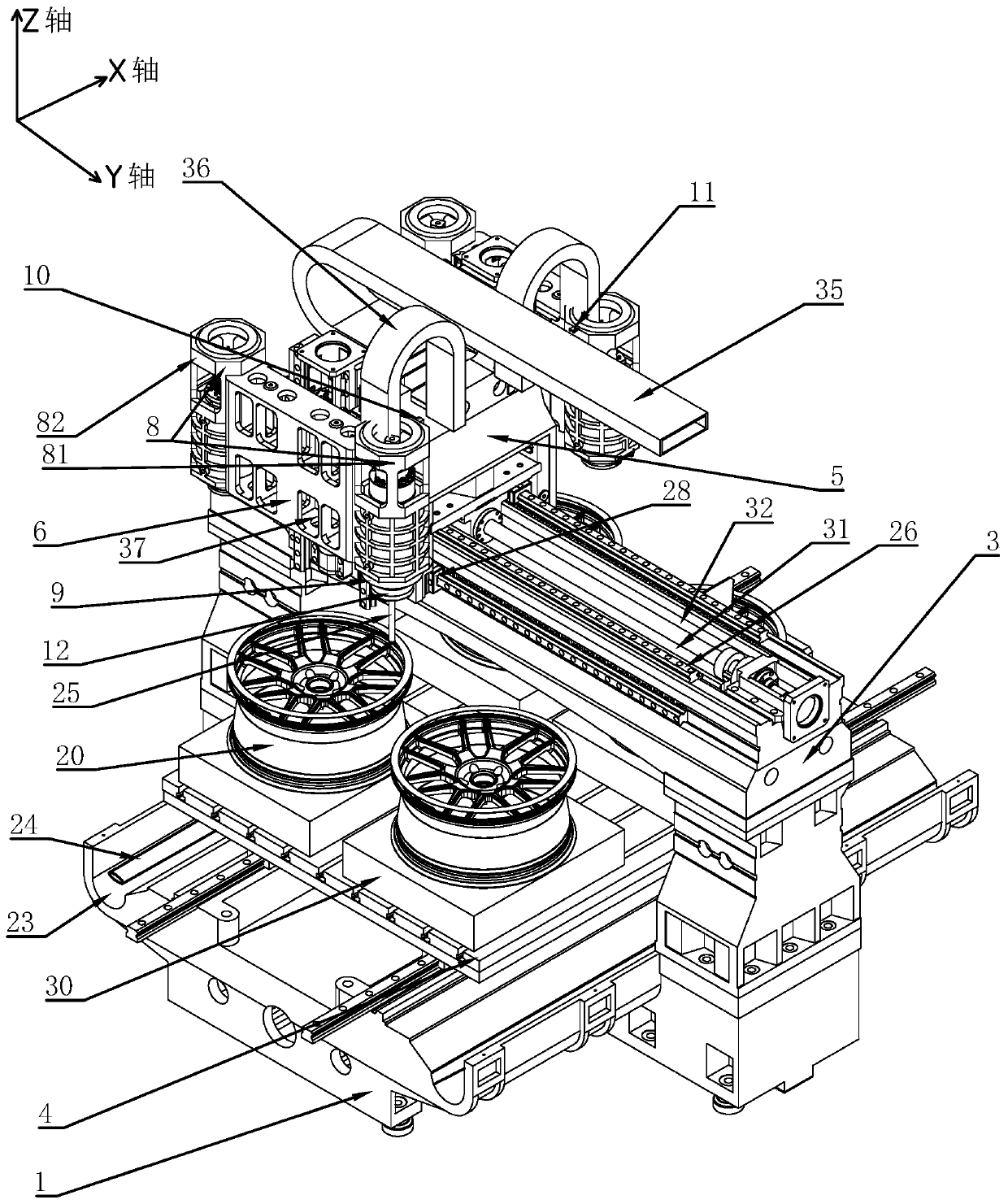

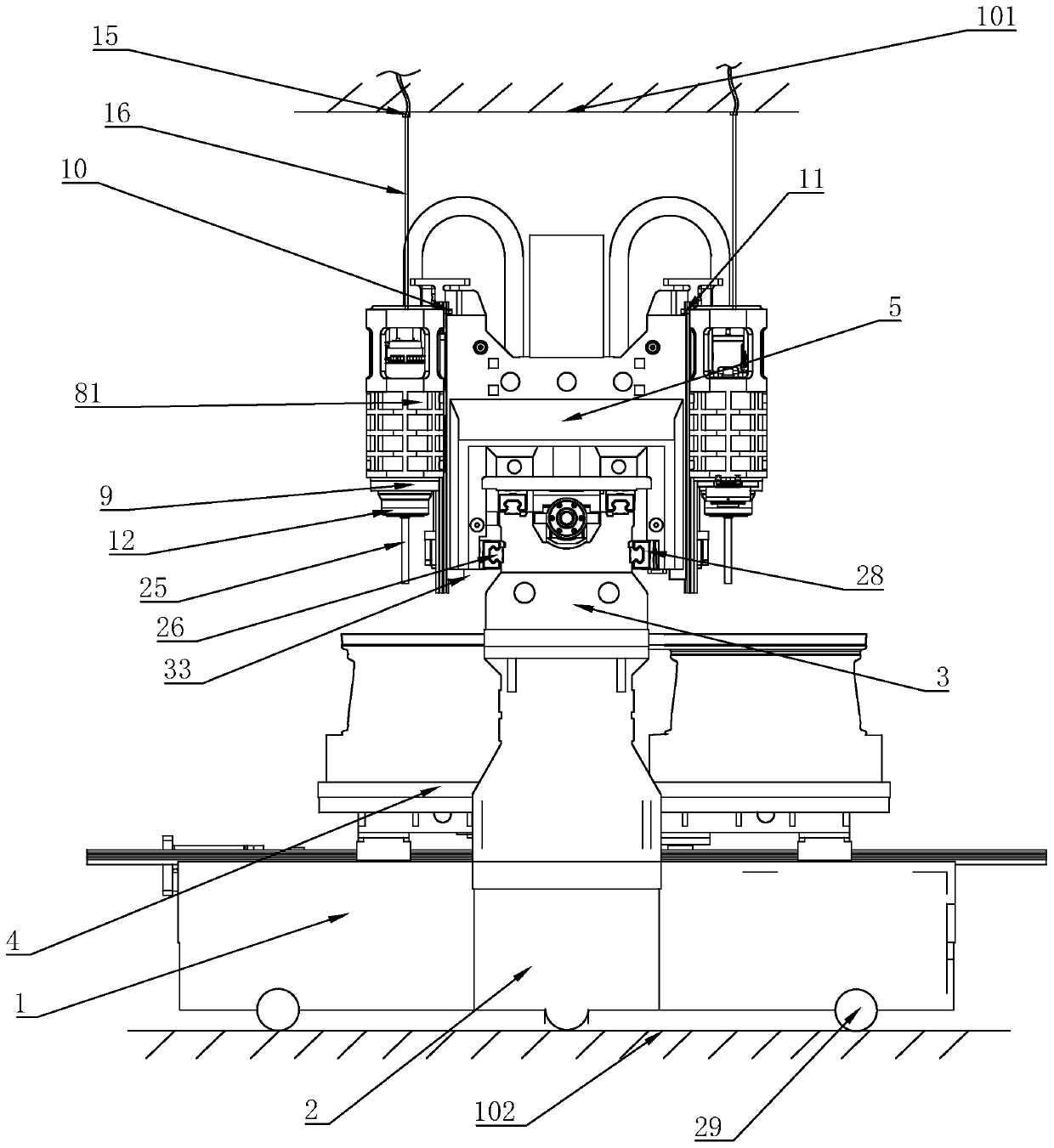

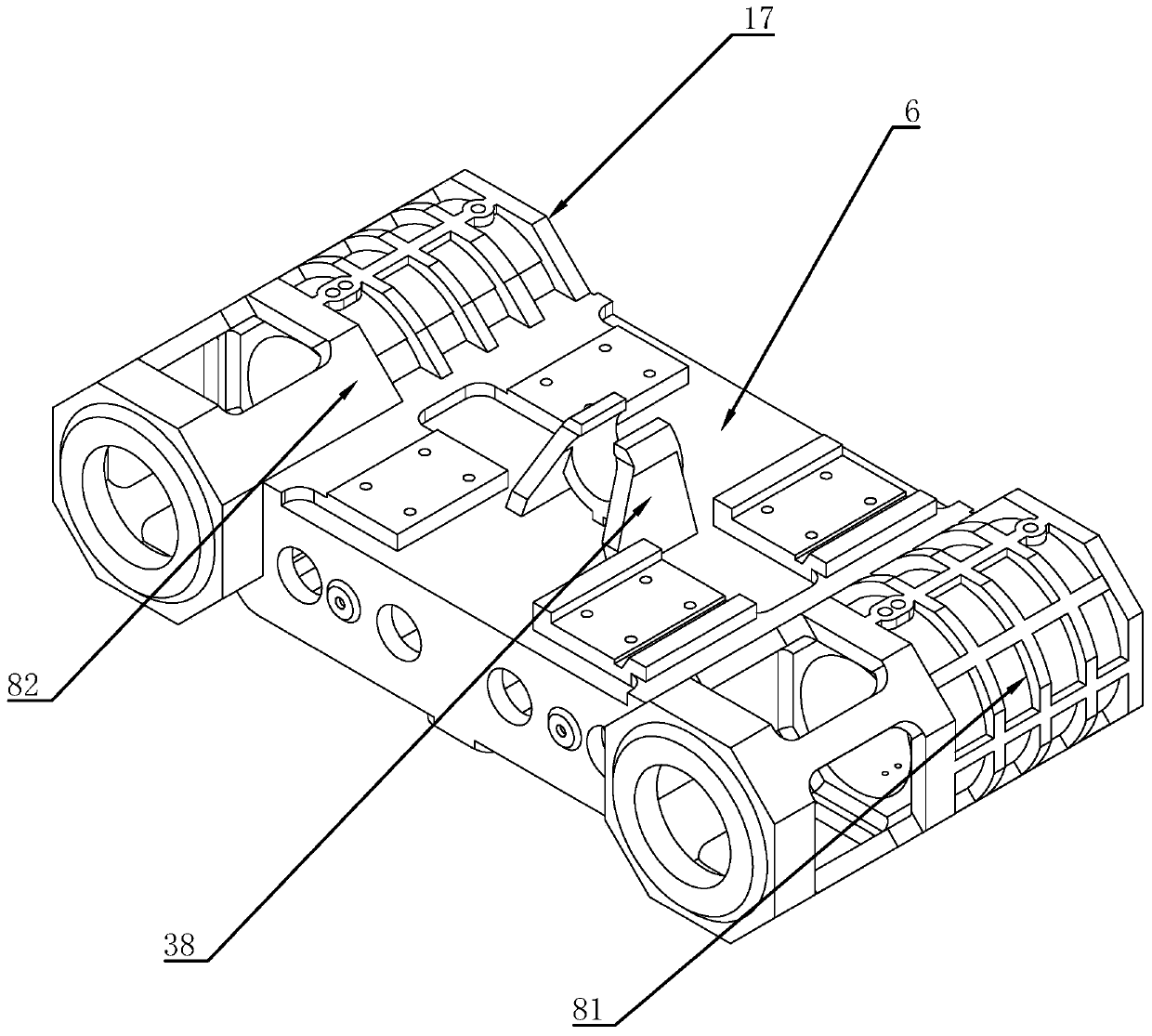

Double-spindle box structure with four-spindle machining center

A technology of spindle processing and dual spindles, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unstable force on the spindle box and affect the processing accuracy, so as to reduce the vibration of the spindle box and improve the processing accuracy , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0065] Example 2 as Figure 1 to Figure 12 Shown: The difference from Example 1 is that two signal transmitters are respectively installed on the front spindle and rear spindle on one headstock, and two signal receivers are respectively installed on the opposite front spindle and rear spindle on the other side of the slide seat. When there are at least three signal receivers receiving the signals from the corresponding signal transmitters, the work will proceed normally.

[0066]The difference from the principle of Embodiment 1 is that the corresponding signal transmitter 10 and the signal receiver 11 are at the same height in the initial state, and during the movement of the front main shaft 9 and the rear main shaft 9 to the Z-axis direction, one of the front main shaft seats There are respectively two signal transmitters 10 on one of the rear main shaft seats, and these four signal transmitters 10 can emit signals all the time. The two signal receivers 11 can receive signals

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap