Claw type vacuum pump

A claw-type vacuum pump and claw-type technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of vacuum pumps that can no longer be used, easy to block channels, gas condensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

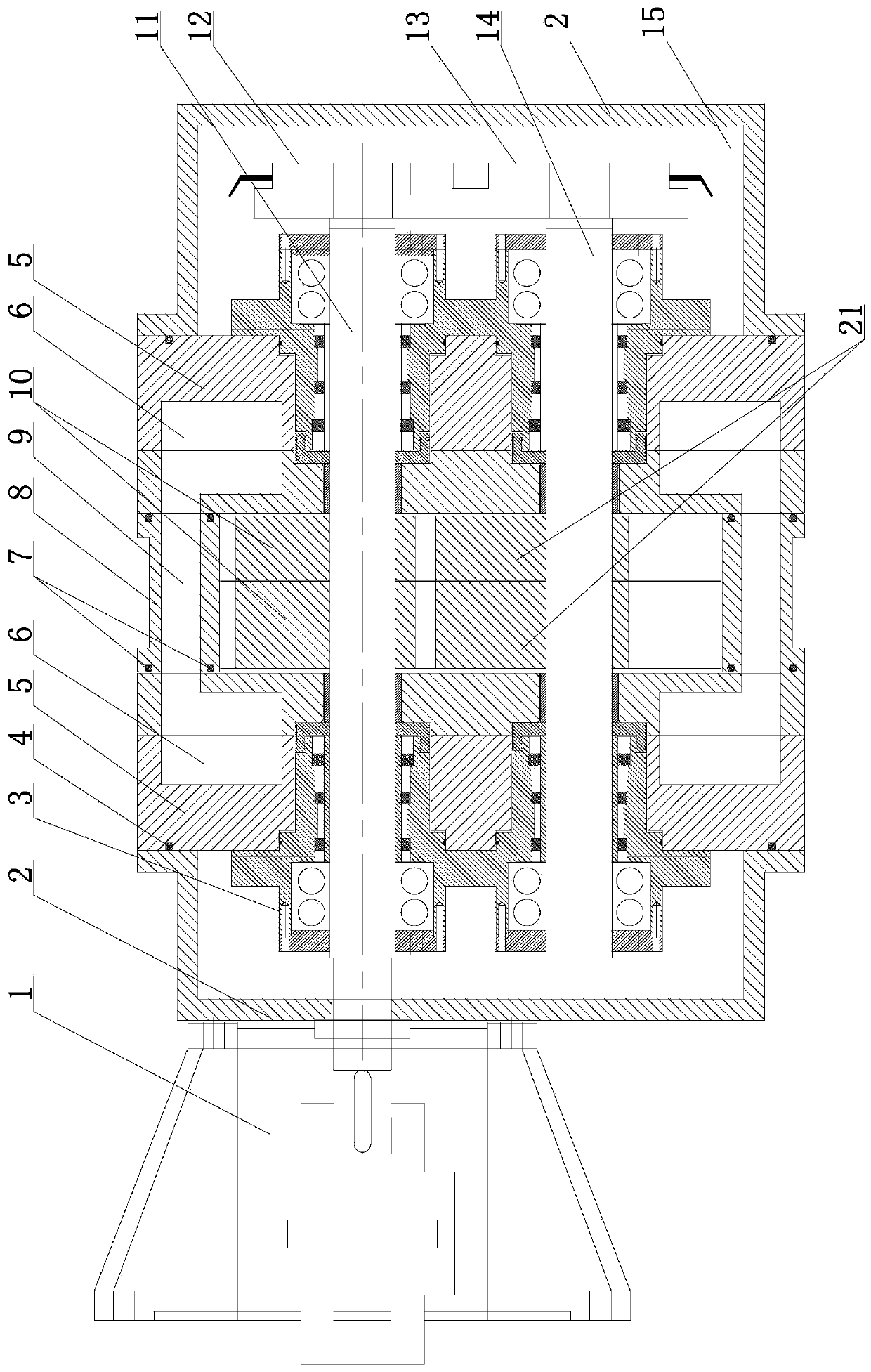

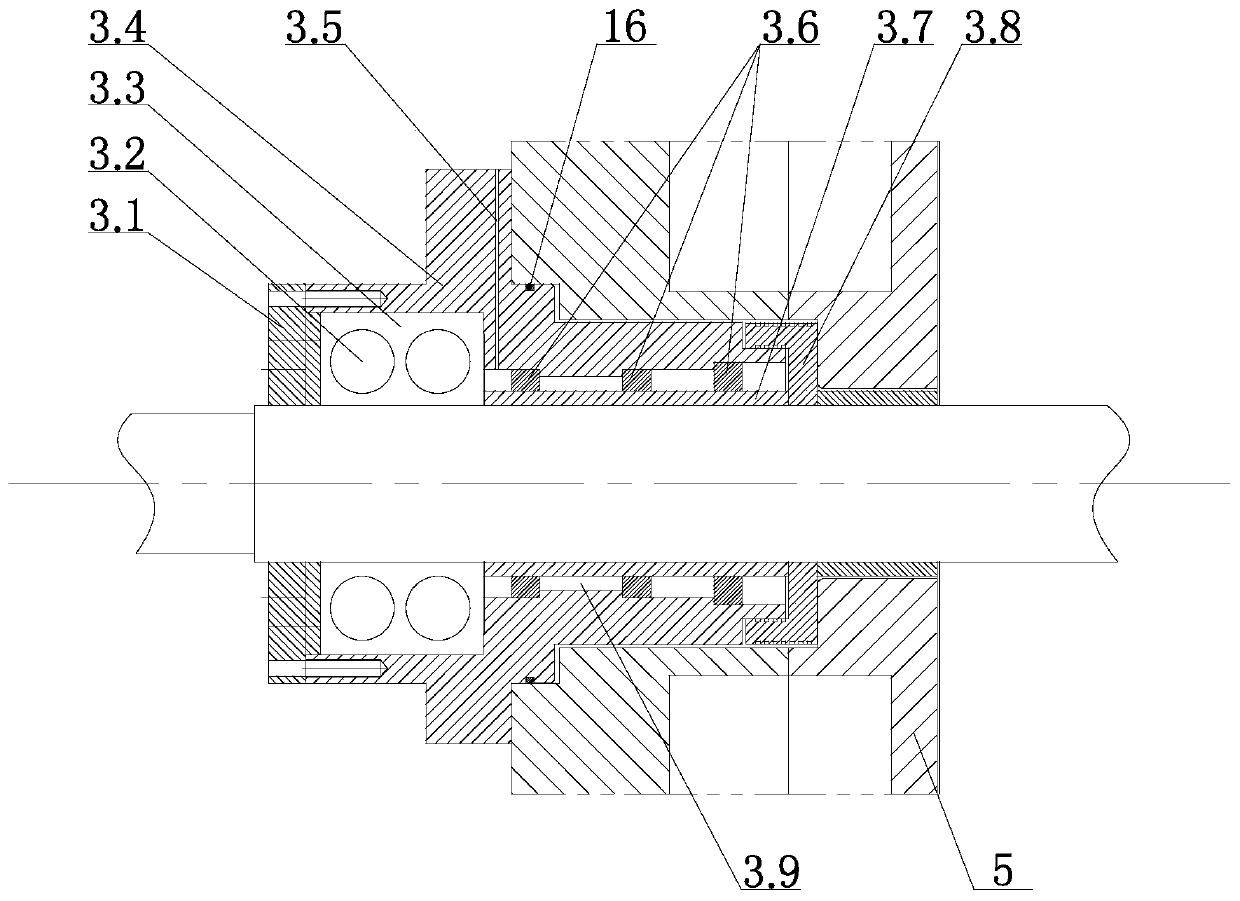

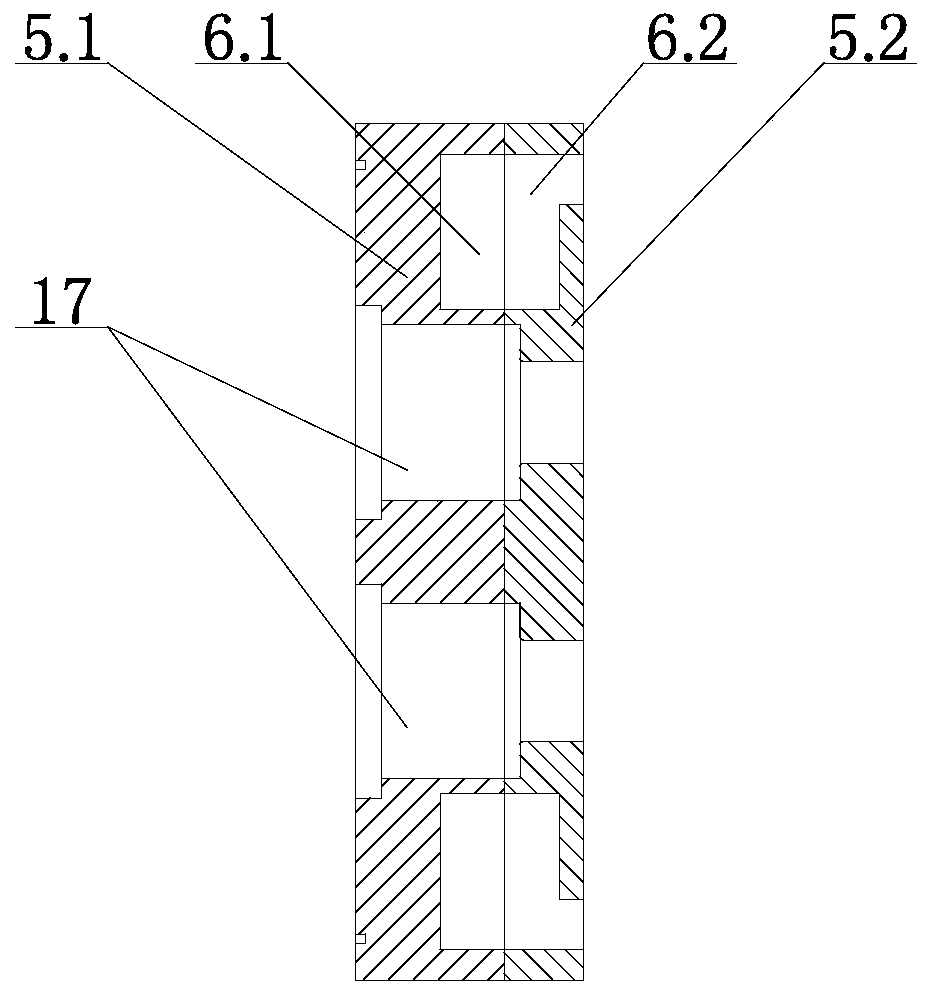

[0036] Such as Figure 1-9 As shown, the claw-type vacuum pump in this embodiment includes a pump body 8, a sealing plate 5 installed at the front and rear ends of the pump body 8, a pump cavity 19 formed by the pump body 8 and two sealing plates 5, and a pump cavity that runs through the pump cavity horizontally. 19 and the two rotor shafts located on the same horizontal plane and the two claw rotors with the same structure located in the pump chamber 19, the two rotor shafts realize synchronous reverse rotation through the gear transmission mechanism (that is, a pair of gears that mesh with each other and have the same number of modulus teeth). Rotate, the two claw rotors are respectively installed on the two rotor shafts and the two are engaged in conjugate engagement. An end cover 2 is respectively installed on the outer sides of the two sealing plates 5, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap