CCD (Charge Coupled Device) vision alignment rear section machine

A visual alignment, back-end technology, applied in the direction of telephone structure, lamination device, lamination auxiliary operation, etc., can solve the problems of labor-intensive, affecting the processing efficiency, processing accuracy and error of the backlight source, and improve the film The effect of fitting precision, manpower saving, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

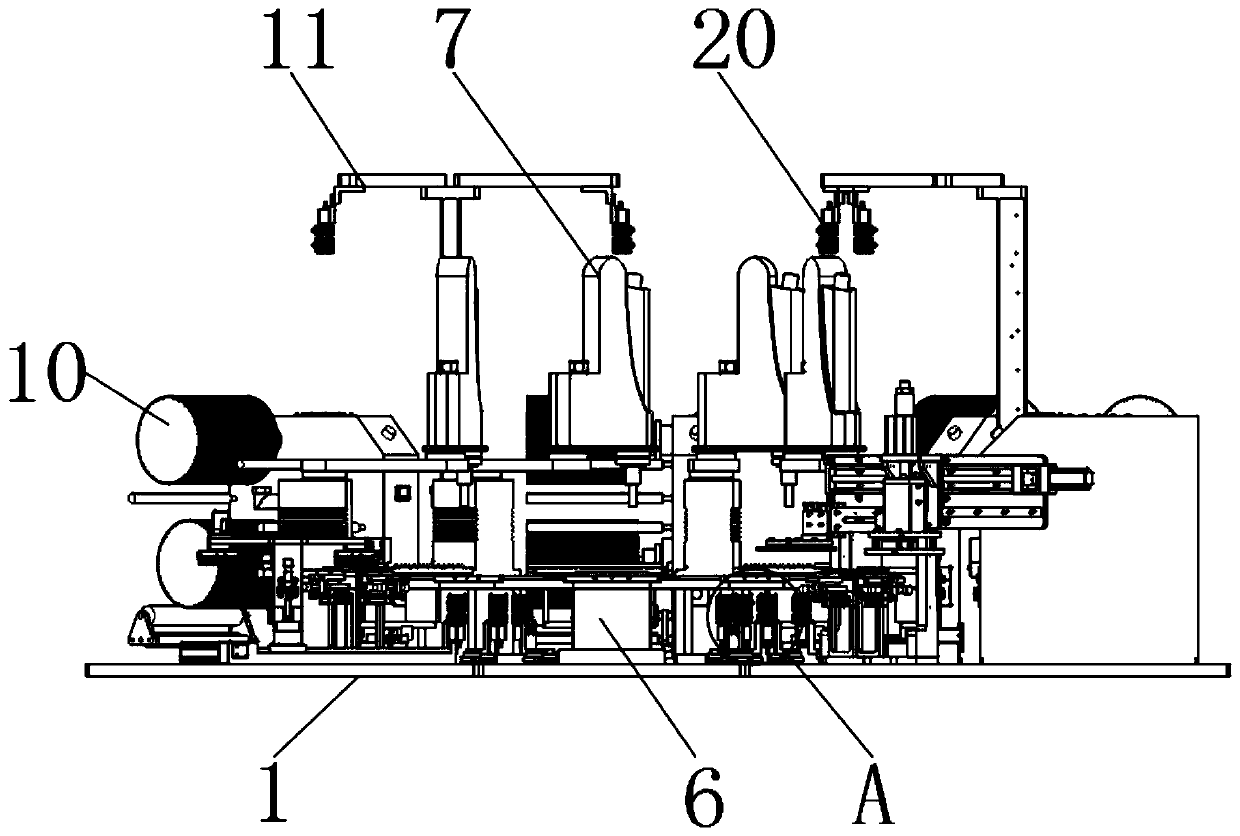

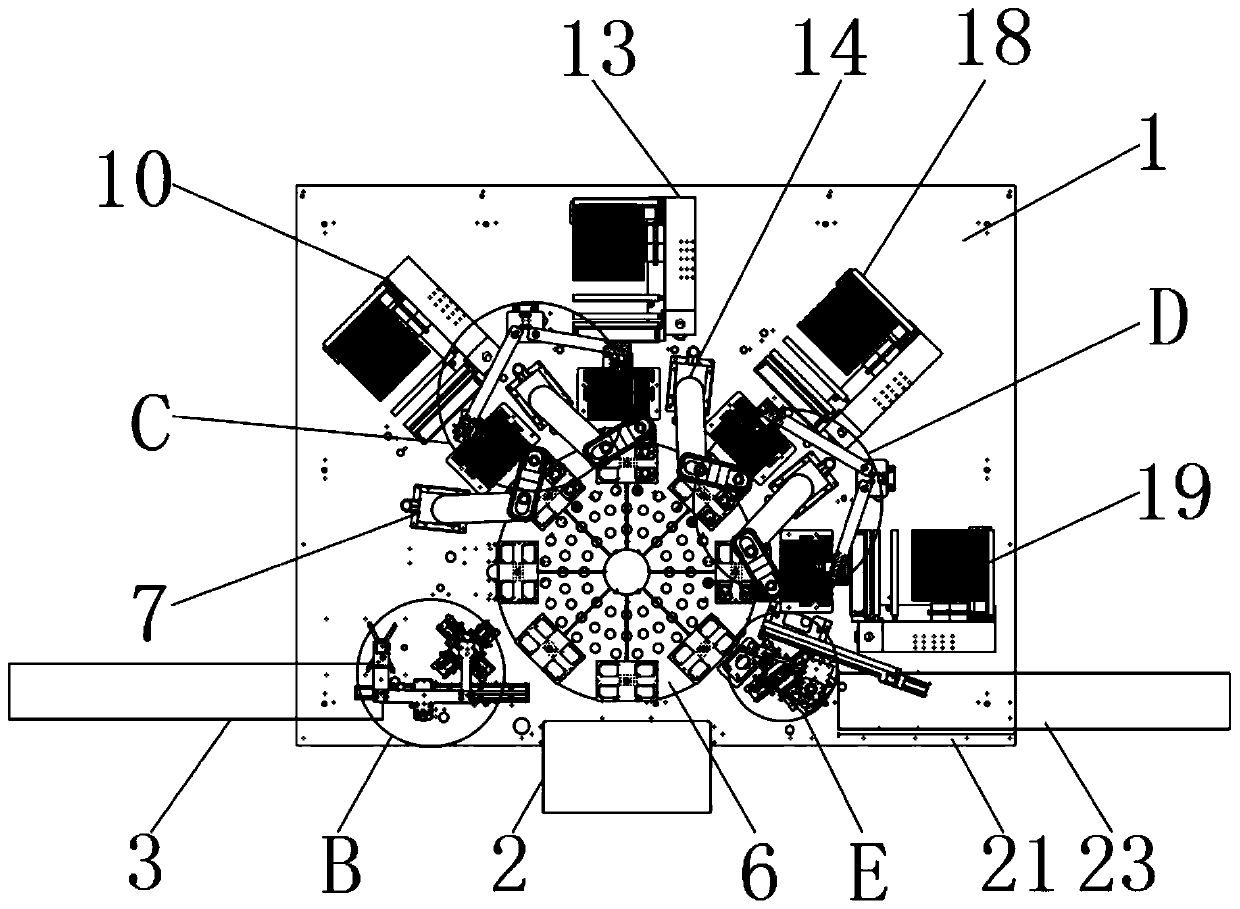

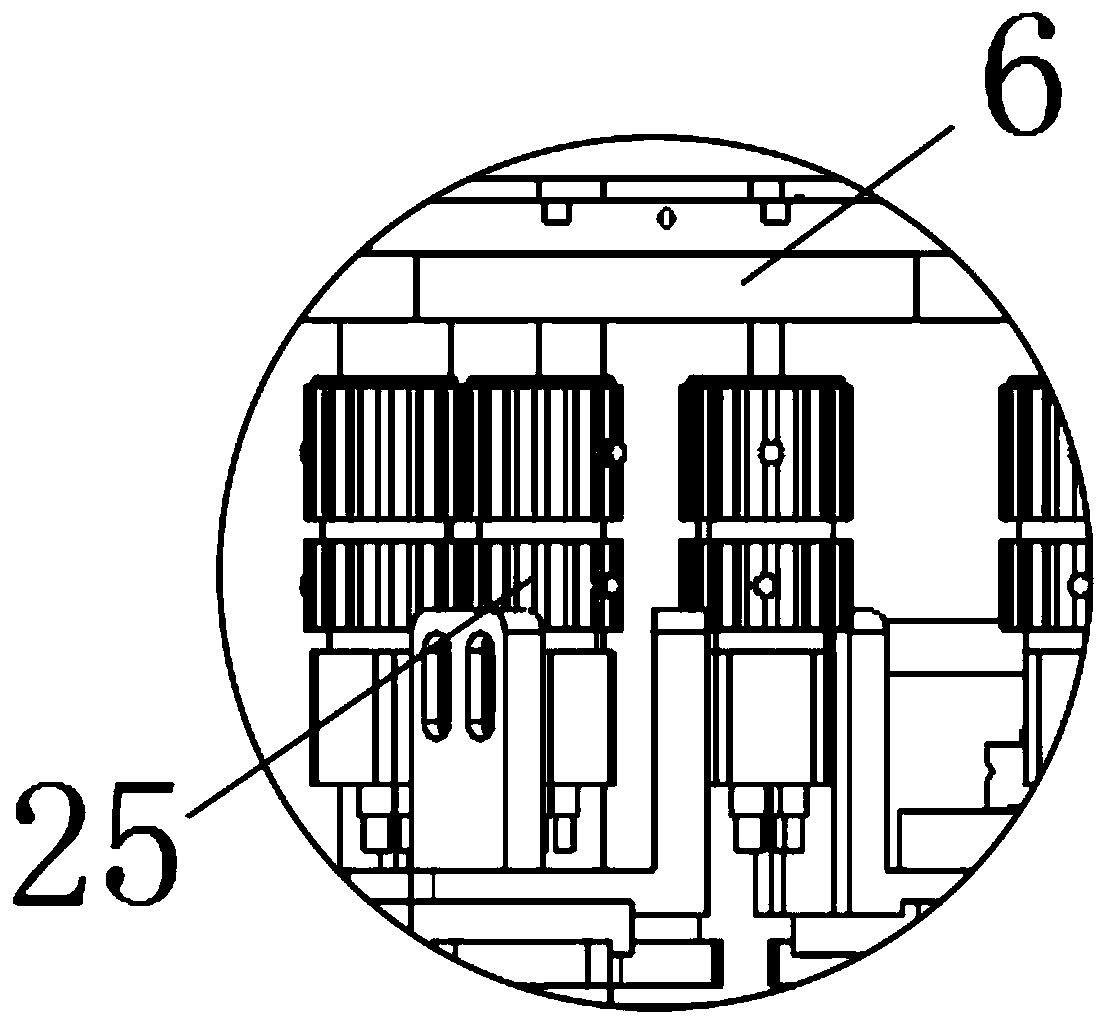

[0032] Specific implementation method: when it is necessary to carry out back-stage processing and production of the mobile phone backlight, firstly, the feeding manipulator 4 will absorb the backlight delivered by the feeding mechanism 3 to the vacuum transfer basin mechanism 6, and at the same time, the feeding manipulator 4 will pass through the first four sides The mechanical correction mechanism 5 accurately corrects and aligns the feeding robot 4, the vacuum transfer mechanism 6 transmits the backlight to the first transmission robot, and the first transmission robot passes the diffusion film at the first film material discharge mechanism 10 through the second A retrieving camera mechanism 11 is accurately attached to the backlight, and the vacuum transfer mechanism 6 transfers the backlight with the diffusion film attached to the second transmission manipulator 9, and the second transmission manipulator 9 puts the second material receiving platform 12 onto the backlight. Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap