Ammonia gas supply device

A supply device and ammonia gas technology, applied in the direction of gas/liquid distribution and storage, fixed catheter components, pipeline systems, etc., can solve the problems of increasing the water content of ammonia gas, unstable ammonia gas supply, reducing ammonia gas concentration, etc., to achieve Reduce risks, save production time and costs, and achieve high-quality output effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

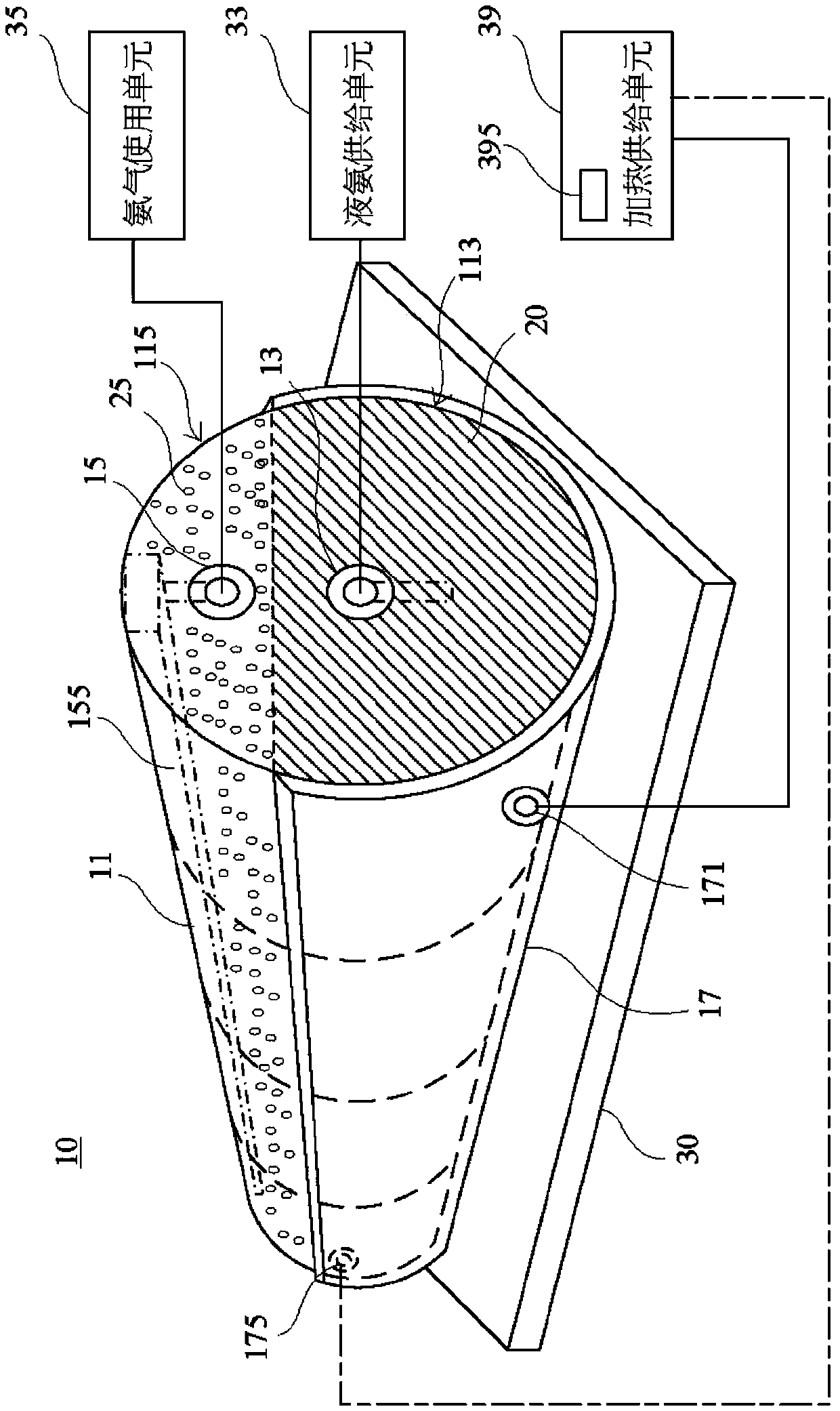

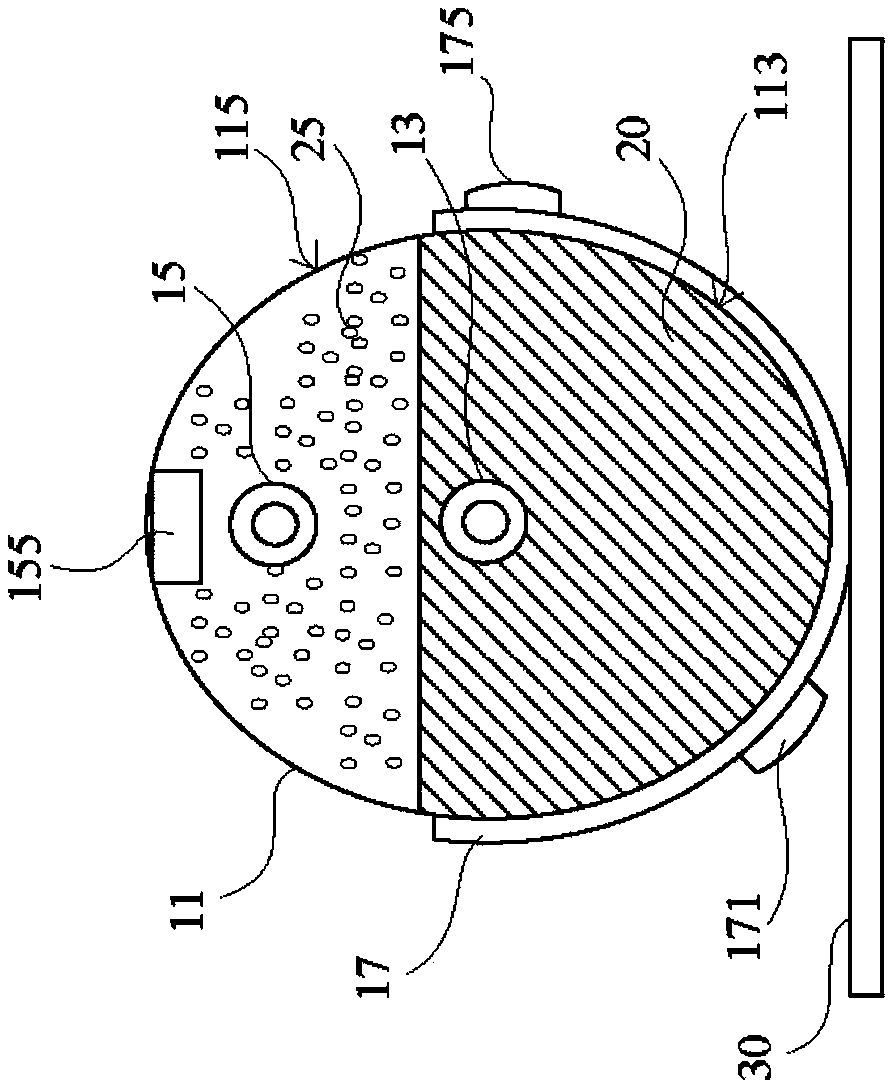

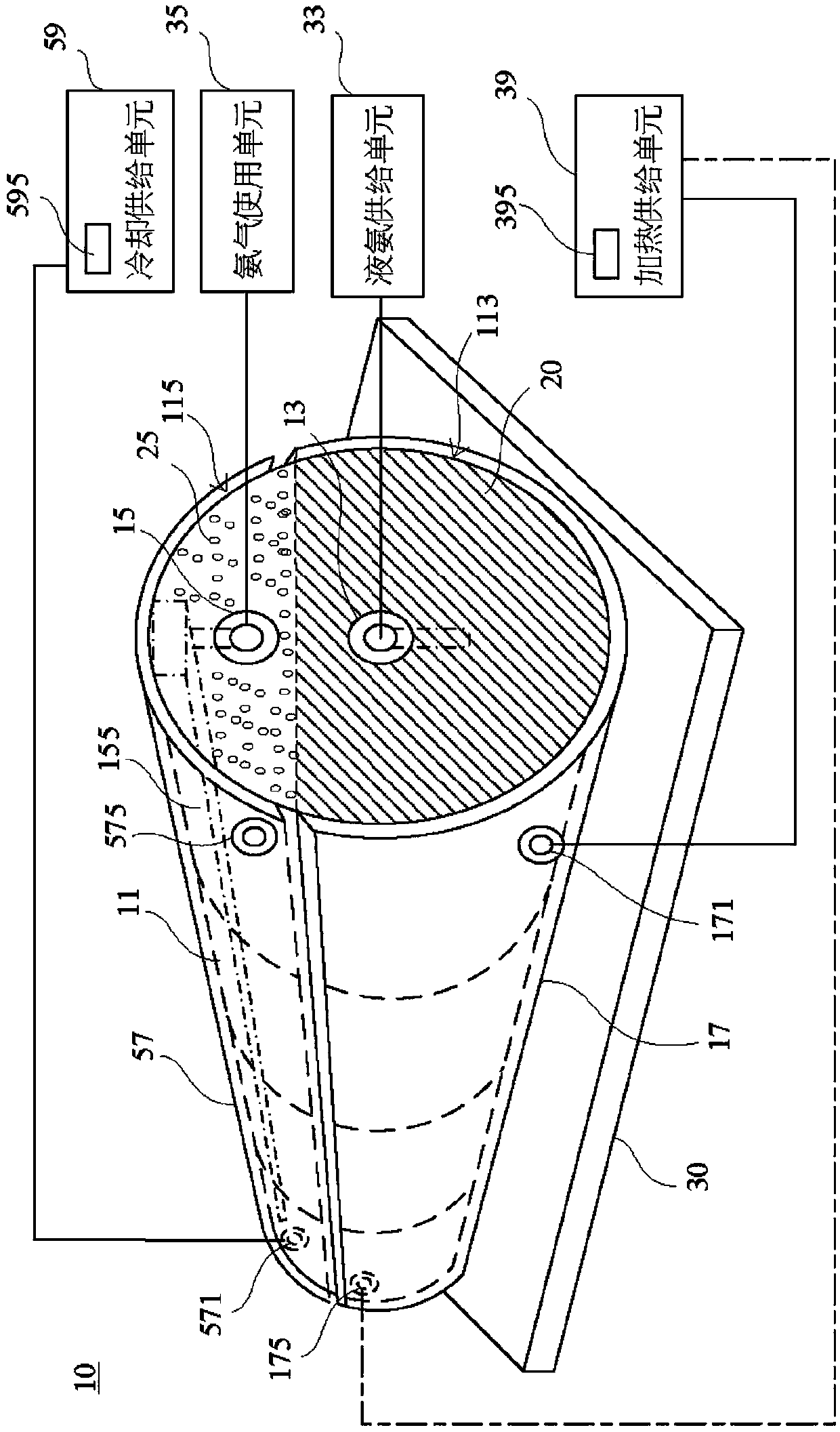

[0033] First, see figure 1 and figure 2 , are a schematic structural diagram and a side view of an embodiment of the ammonia gas supply device of the present invention, respectively. As shown in the figure, the ammonia gas supply device 10 of the present invention is mainly a fixed storage tank 11, such as but not limited to a fixed storage tank 11 that can be fixed on a plant substrate 30. The fixed storage tank 11 can be used for A liquid ammonia 20 is stored, and one side of the fixed storage tank 11 is provided with a liquid ammonia inlet and outlet piece 13 and an ammonia gas output piece 15 . The liquid ammonia inlet and outlet member 13 can be connected to a liquid ammonia supply unit 33, such as but not limited to a liquid ammonia supply unit 33 in the same workshop as the workshop substrate 30, which can be adjusted according to the capacity of the liquid ammonia 20 in the fixed storage tank 11. The liquid ammonia 20 is replenished in a timely manner into the fixed st

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap