USBC cable testing circuit

A cable testing and circuit technology, which is applied in the field of USBC cable testing circuits, can solve problems such as product hidden dangers, open circuits, short circuits, etc., and achieve the effect of accurate testing and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

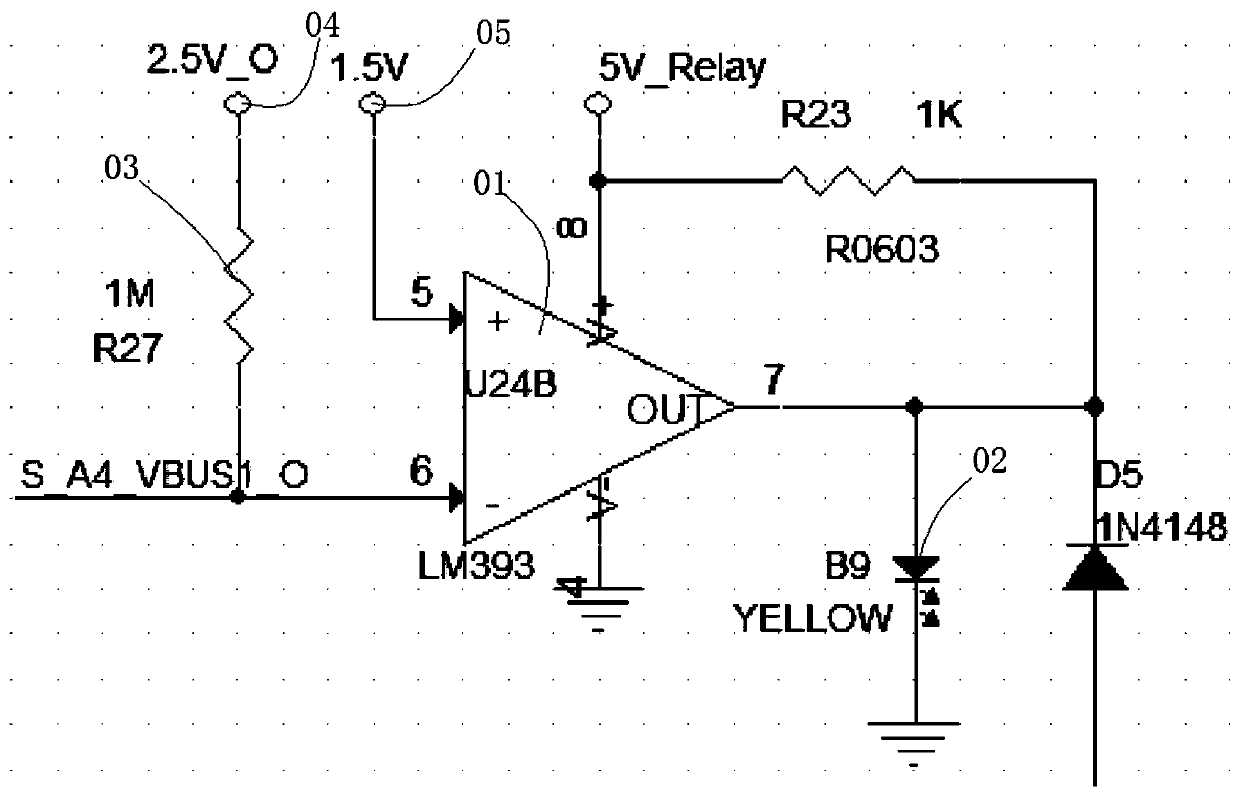

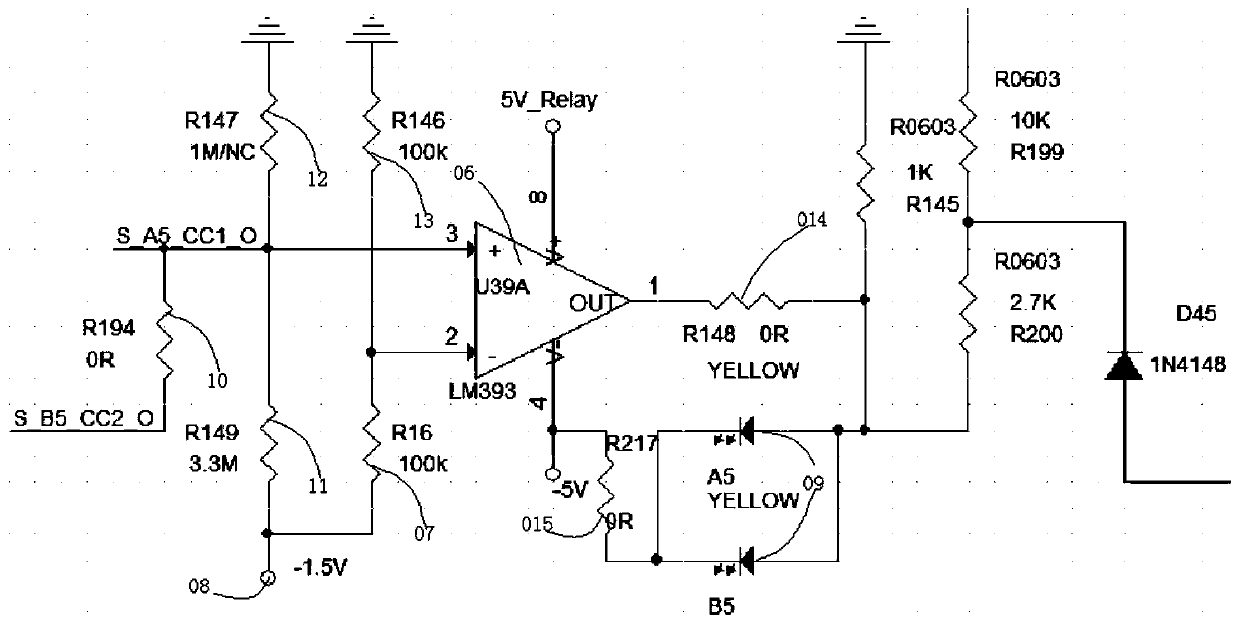

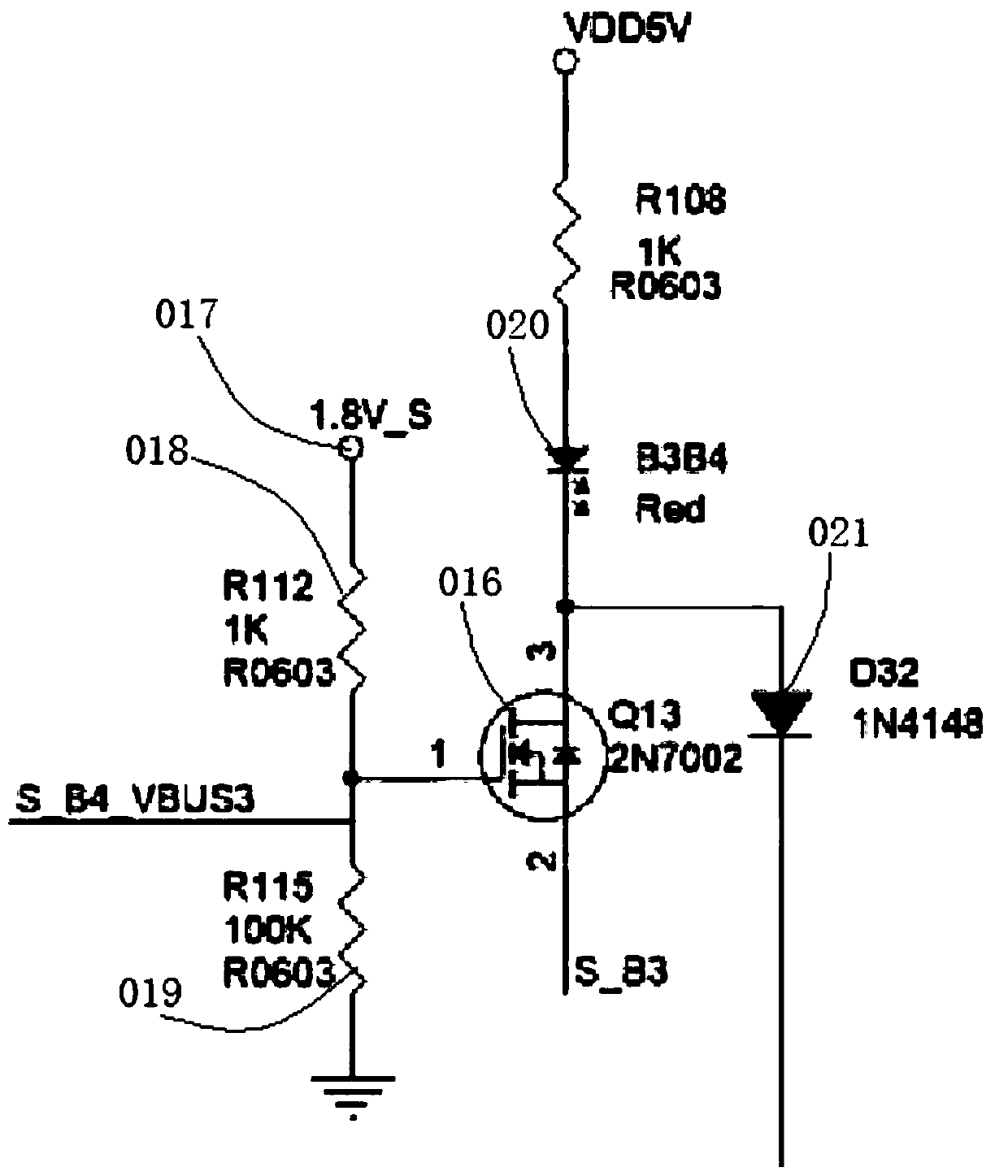

[0016] Such as figure 1 Shown, the USBC cable test circuit, it includes several positive voltage modules for testing the positive voltage of the USBC connector open circuit and negative voltage modules for testing the negative voltage and several short circuit test modules for testing the short circuit test of the USBC connector, the USBC cable The 24 pins take two adjacent pins as a group to form 22 sets of pin pairs, and the two pin pairs opposite to the front and back of the USBC form a pin pair group. The positive voltage module is used to test the connection to a low-impedance pin pair, the negative voltage module is used to test a high-impedance pin pair;

[0017] Each positive voltage module 41 includes a first comparator 01, an indicator light 02 connected to the output terminal of the first comparator, and a first power supply connected

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap