Impact-reducing support structure suitable for single machine with small heat conduction amount requirement on spacecraft

A technology of support structure and thermal conductivity, which is applied to space navigation equipment, space navigation aircraft, aircraft and other directions, can solve the problems of not considering related design, complex device structure, etc., and achieves light structure, wide application range and bearing capacity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

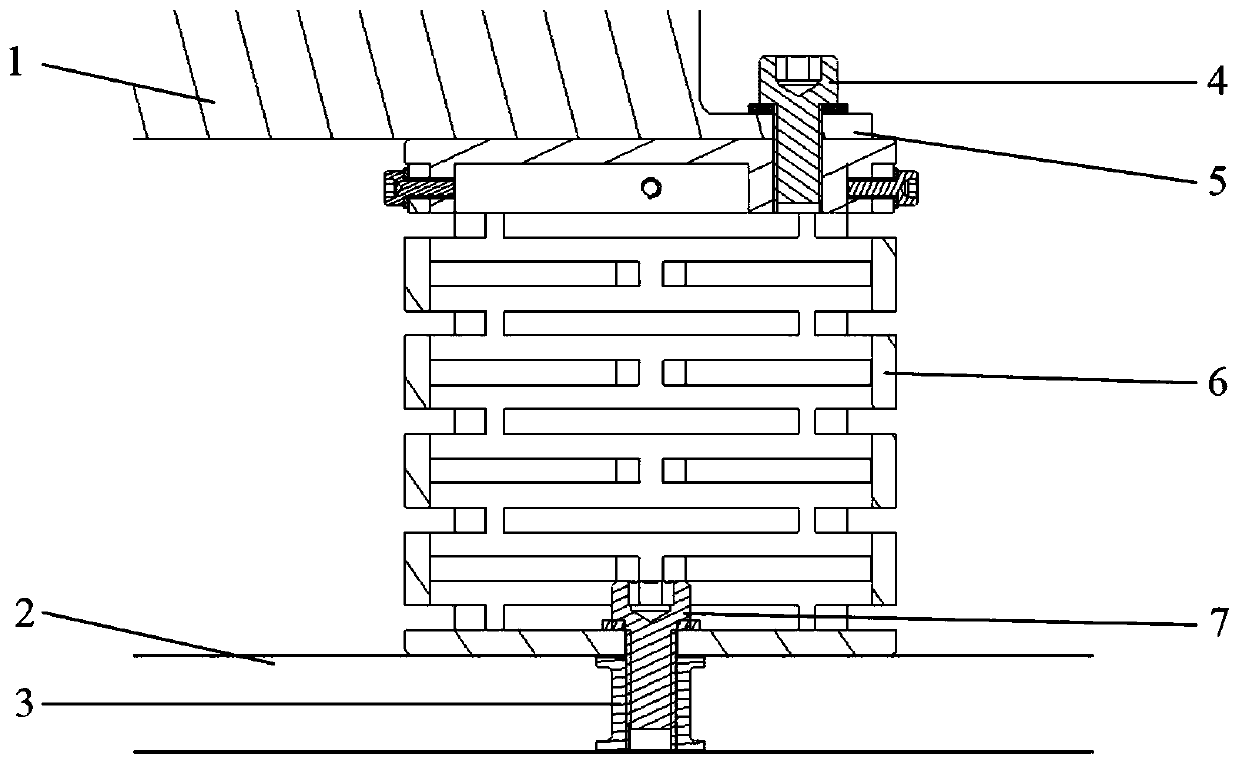

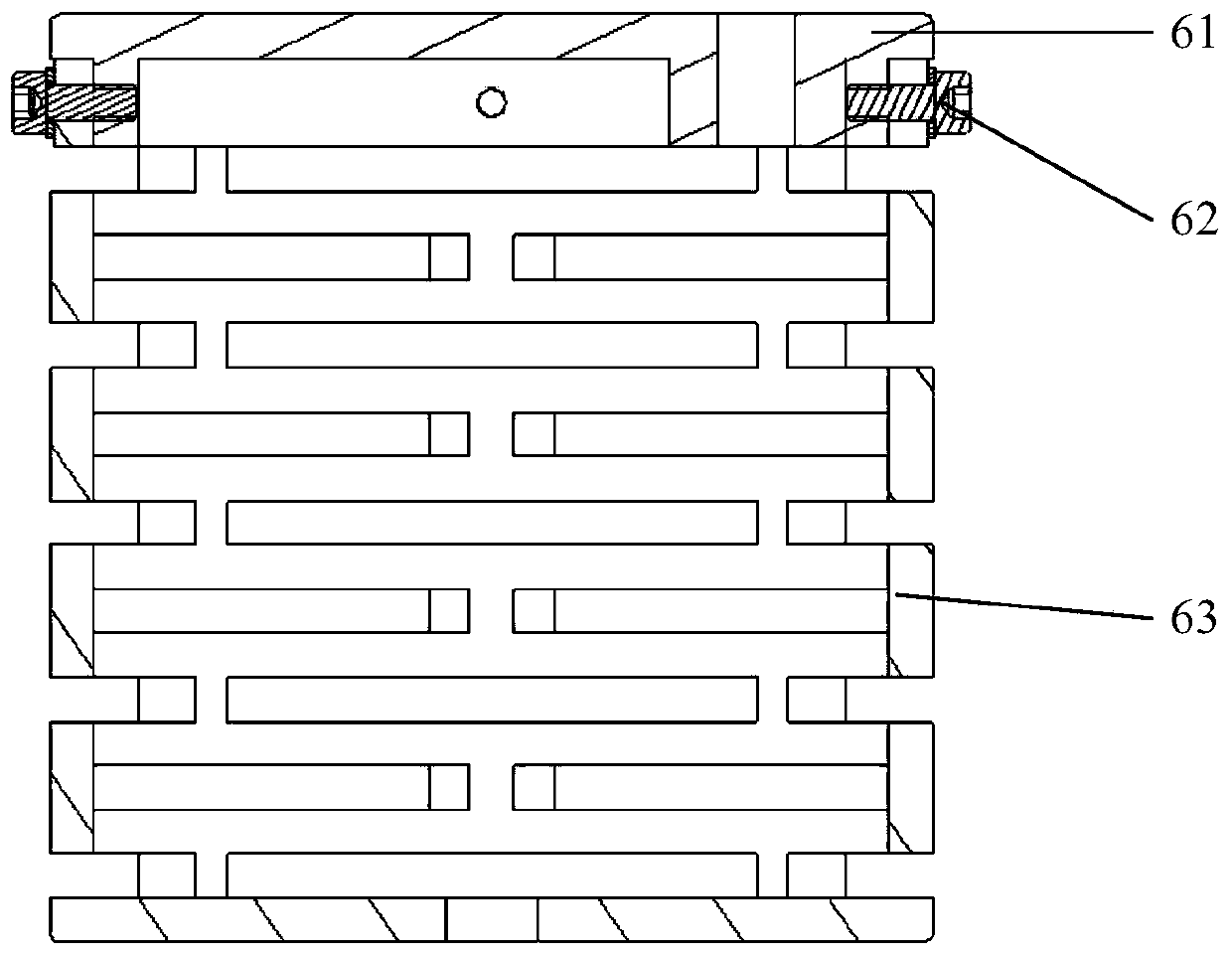

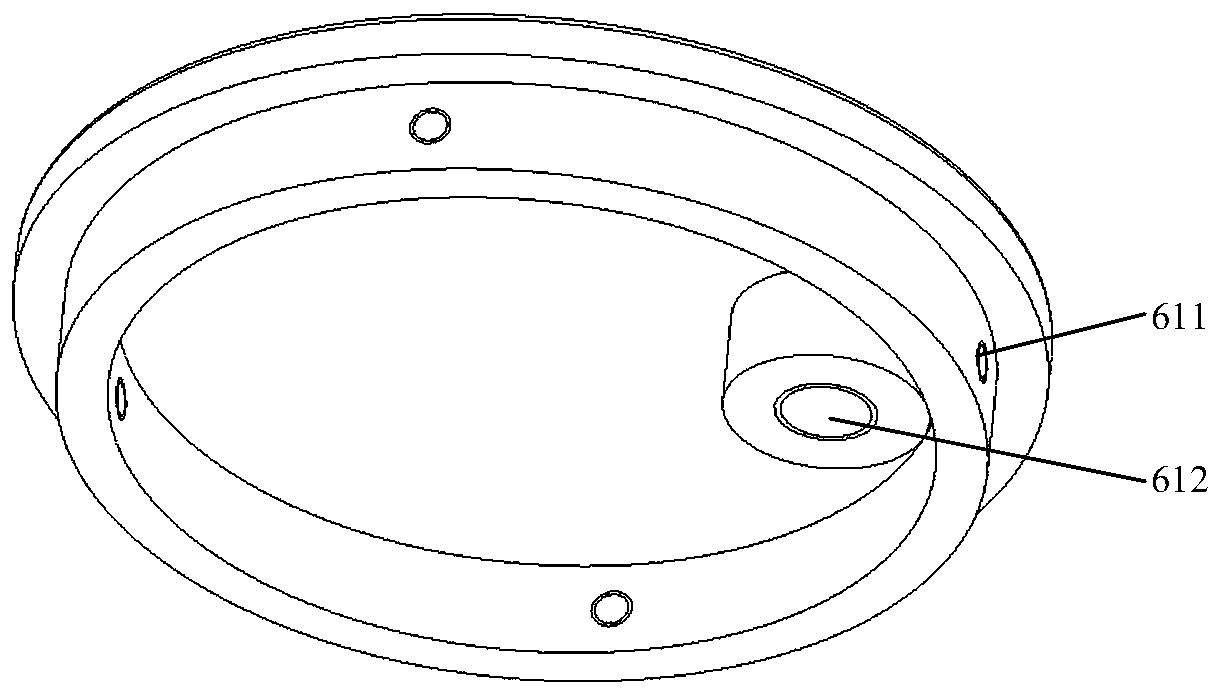

[0027] In this embodiment, the invention relates to a shock-absorbing support structure suitable for a single machine with a small demand for heat conduction on a spacecraft. The shock-absorbing support structure includes an upper fastening device, a shock-reducing support, a lower fastening device and connecting embedded parts ; The anti-shock bracket provides threaded mounting holes for the single machine; the single-machine mounting feet are through holes, and are connected to the single machine through fastening screws and compression washers; The components are set in the honeycomb panel to provide threaded installation holes for the impact reduction bracket. The installation holes of the impact reduction bracket and the honeycomb panel are through holes, and are connected to the single machine through fastening screws and compression washers.

[0028] Next, the present invention will be described in detail.

[0029] The shock-reducing support structure of the present invent

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap