Connector and shell assembly thereof

A technology of housing components and connectors, which is applied to the parts, connections, and electrical components of the connection device, which can solve the problems of weakening the temperature rise of the contacts, achieve temperature rise suppression, avoid blocking, and have significant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

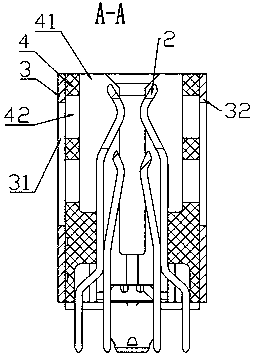

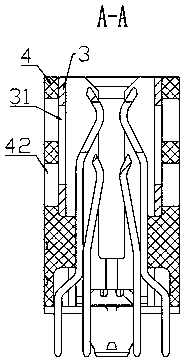

[0039] Embodiment 2 of the connector of the present invention is different from Embodiment 1 in that: image 3 As shown, the aforementioned metal thermally conductive layer 3 can be pasted and fixed on the inner wall of the insulator 4, which can also achieve effective control of the heat generated by the temperature rise of the contact 2.

[0040] Embodiment 3 of the connector of the present invention is different from Embodiment 1 in that: Figure 4 As shown, there may be two metal heat-conducting layers 3 in the same heat dissipation channel, one corresponding insulator heat-dissipating hole 42, and two heat-conducting layer heat-dissipating holes 31 communicate with the same insulator heat-dissipating hole 42, so as to realize heat dissipation. At the same time, the connecting portion between the two heat-conducting layer heat dissipation holes 31 may also form a heat conducting portion 32.

[0041] In other embodiments, the heat conduction portion 32 may be formed by the two sides

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap