Portable numerical control equipment comprehensive performance detection and analysis platform and analysis method

A comprehensive performance, portable technology, applied in the direction of measuring device, program control, computer control, etc., can solve the problems of large size and weight of the device, waste of data, and difficult to achieve portable movement and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

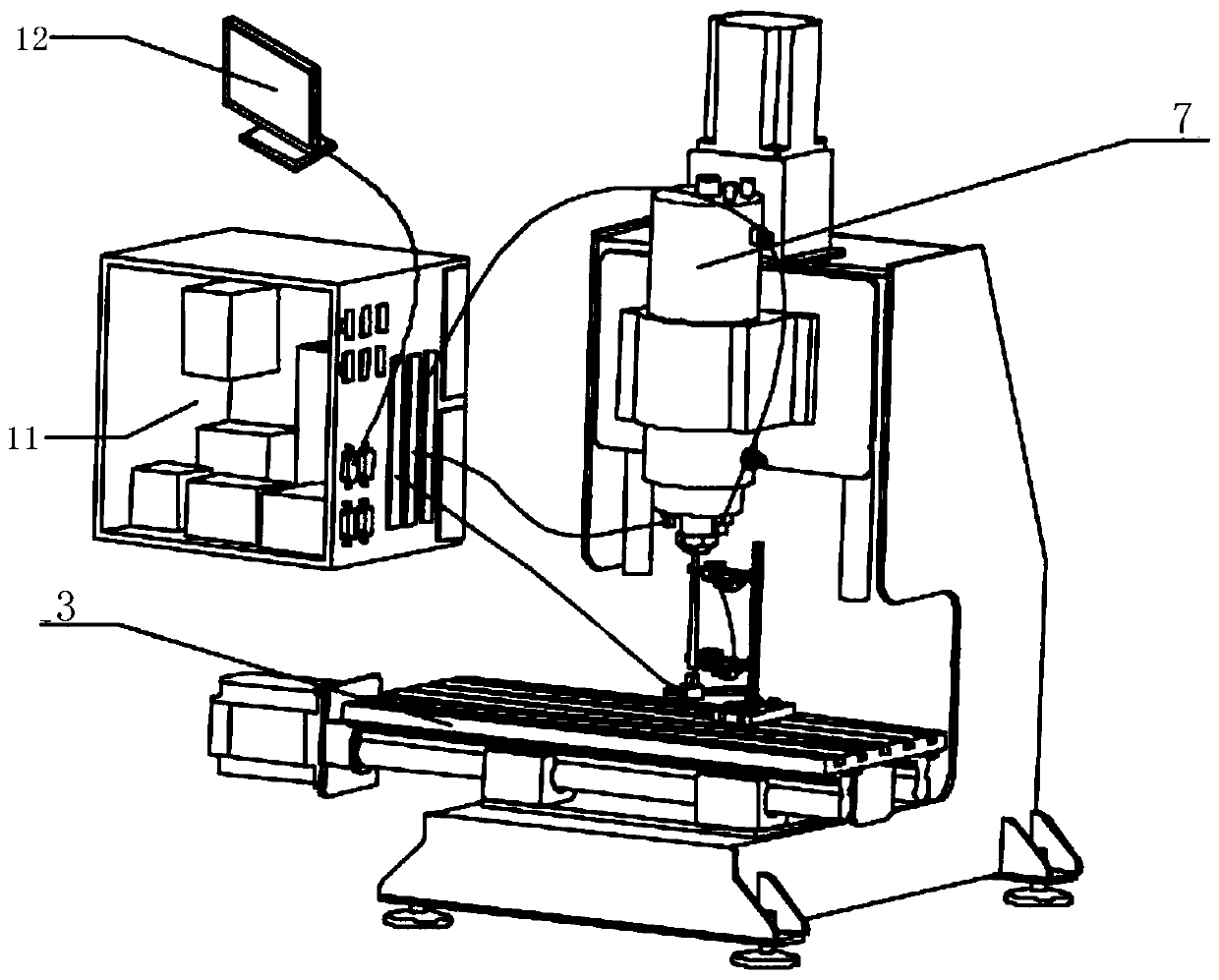

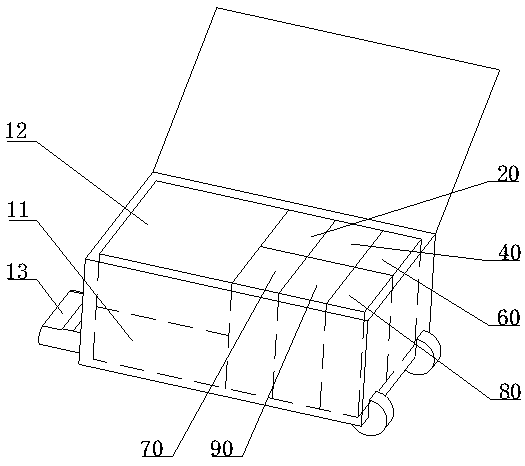

[0112] Embodiment 1: A portable numerical control equipment comprehensive performance detection device

[0113] see Figure 1 to Figure 11 As shown, a portable numerical control equipment comprehensive performance detection and analysis platform, which includes: a detection server, a displacement detection component, a temperature detection component, a vibration detection component, a noise detection component, a current detection component, a current detection component, and a detection platform box 13;

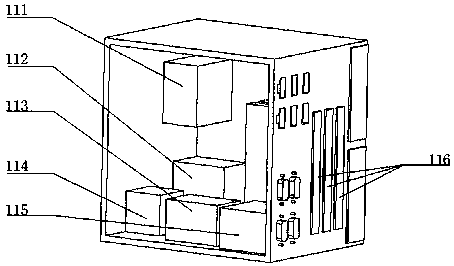

[0114] The detection platform box 13 includes a box body, wheels, pull rods and a cover, etc.; the box body is divided into left and right sides, the left side is placed with a detection server, and the right side is respectively provided with a plurality of component storage areas, specifically It is subdivided into six blocks, respectively placing displacement detection components, temperature detection components, vibration detection components, noise detection components,

Embodiment 2

[0158] Embodiment 2: A displacement detection method of a portable numerical control equipment comprehensive performance detection and analysis platform

[0159] see Figures 2 to 11 As shown, a portable numerical control equipment comprehensive performance detection and analysis platform displacement detection method;

[0160] The displacement detection method includes: single-point displacement detection, two-point displacement detection, five-point displacement detection;

[0161] Single-point displacement detection:

[0162] The components used in the single-point displacement detection include: test rod 21, displacement sensor I221, displacement sensor bracket, floor seat 24, column 25, slider seat I261;

[0163] The test rod 21 is a cylinder;

[0164] The tail of the displacement sensor I221 is provided with a square slider sleeve; the opposite end face is provided with a threaded through hole; the two sides of the square slider sleeve are provided with a bracket sliding

Embodiment 3

[0198] Embodiment 3: A temperature detection method of a portable numerical control equipment comprehensive performance detection and analysis platform

[0199] see Figure 6 As shown, a temperature detection method for the comprehensive performance monitoring component of portable numerical control equipment;

[0200] The temperature detection method adopts a temperature detection component; the temperature sensor is adsorbed by a magnetic suction seat to measure the temperature signal at a position where the temperature needs to be measured, and the temperature signal collected is uploaded to the detection server through the temperature conditioning module 115 and the data acquisition terminal 116;

[0201] For example: the temperature detection component is divided into a tool handle temperature detection component, a lower electric spindle temperature detection component, and an upper electric spindle detection component according to the position of the detection;

[0202] T

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap