Novel high-performance high-voltage high-current connector

A high-current connector, high-performance technology, applied in the direction of vehicle connector, connection, two-component connection device, etc., can solve the problems of inconvenient disassembly, occupying space, difficult operation, etc., achieving good connection reliability, saving cables, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

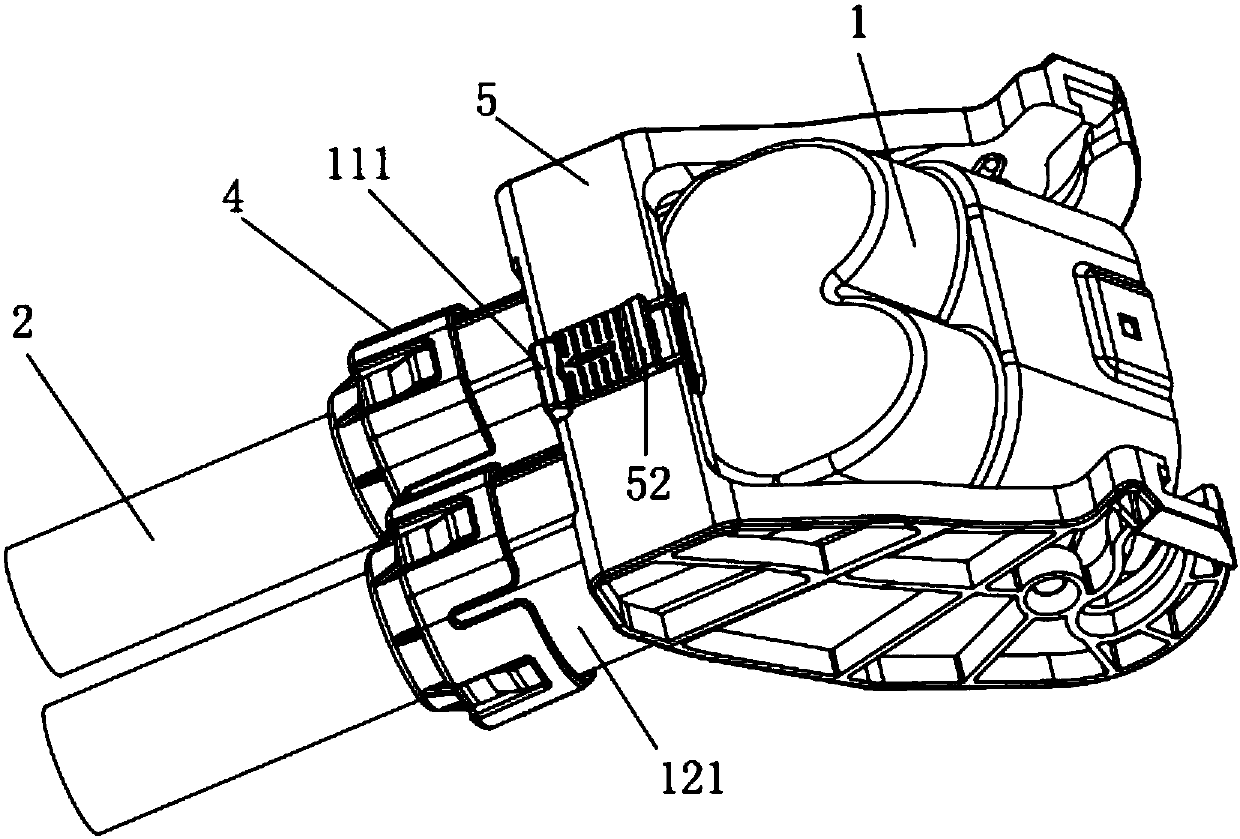

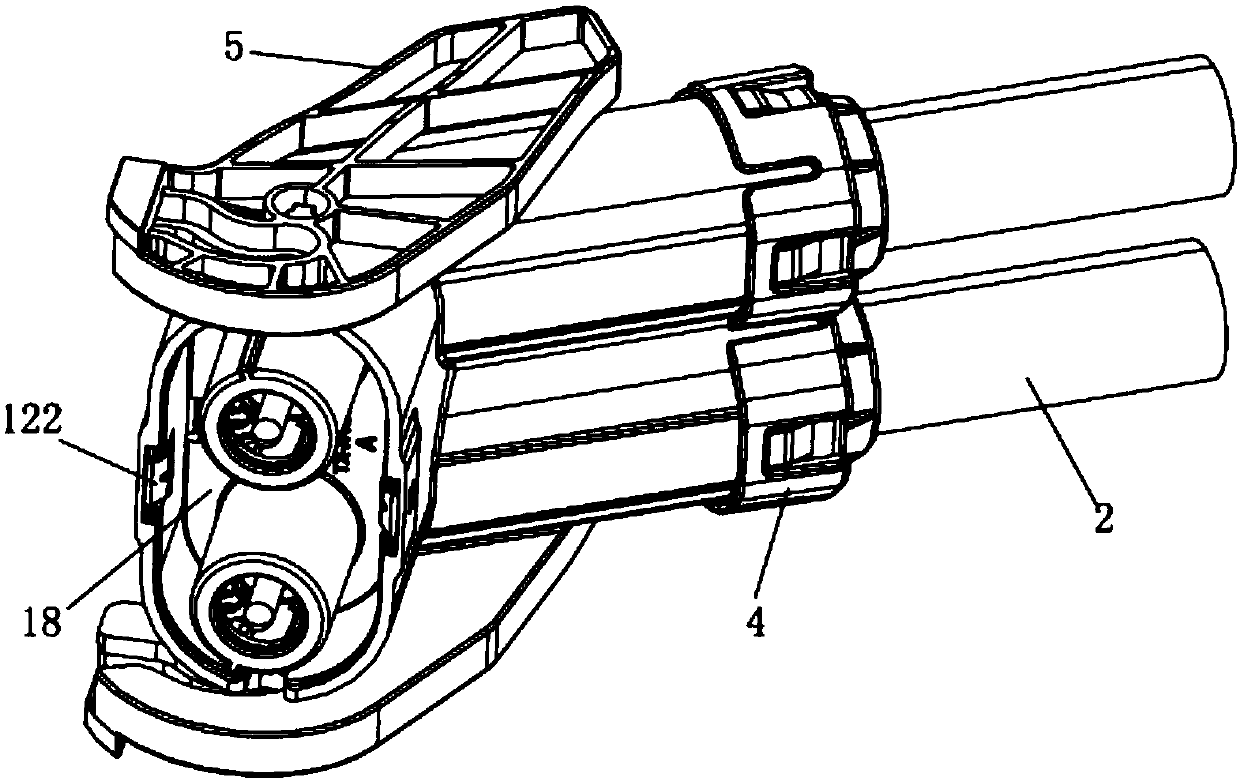

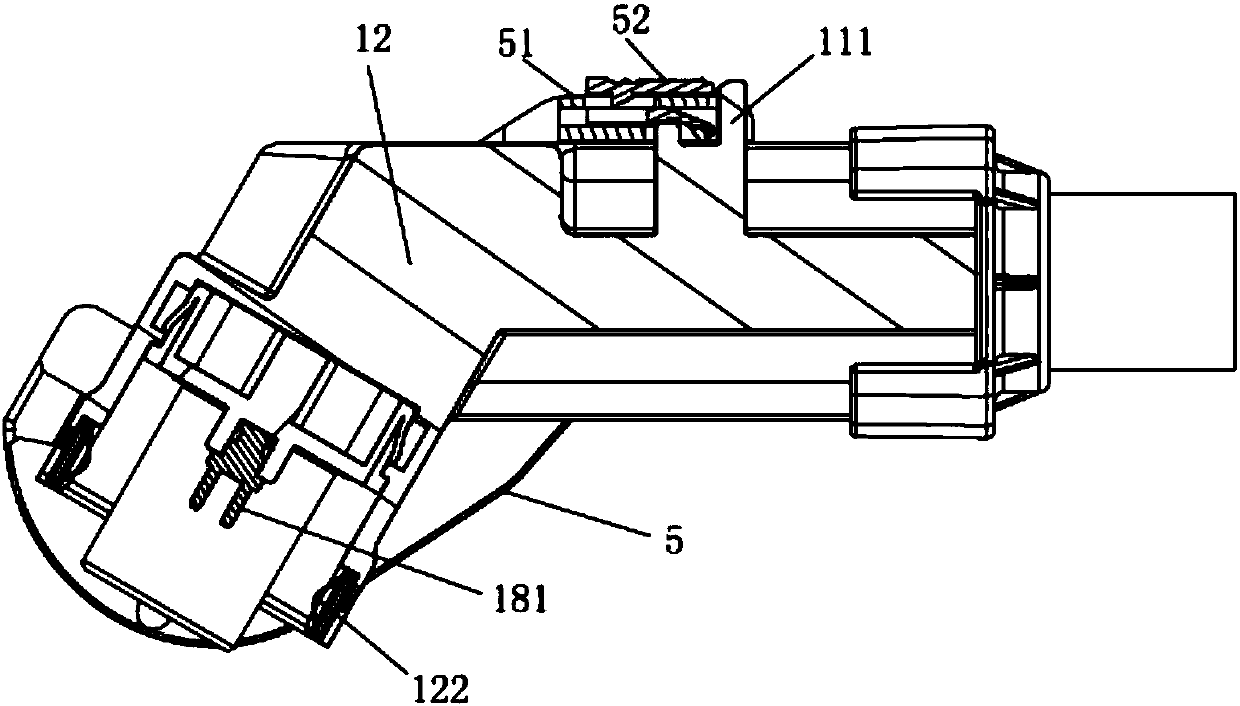

[0027] Such as Figure 1 to Figure 5 As shown, a new high-performance high-voltage and high-current connector shown in this embodiment includes a plug part 1 and a socket part (not shown in the figure) that are mated with each other. The plug part 1 is connected to the plug-end cable 2. Connection, the socket part is connected with the socket end cable (not shown in the figure), the plug part 1 includes a metal shell 11 with a 120-degree corner, one end of the metal shell 11 is connected with the plug end cable 2, and the other end is connected with the socket The components are inserted together, and the middle of the metal shell 11 is a hollow through hole 12 (that is, a through hole 12 is provided in the middle of the metal shell 11 along the direction of the metal shell 11, and the through hole 12 has a corner of 120 degrees like the metal shell 11), located at Two jack assemblies 13 are arranged in the through hole 12 at one end of the metal shell 11 and the socket part; Fo

Embodiment 2

[0030] Such as Figure 1 to Figure 5 As shown, a new type of high-performance high-voltage and high-current connector shown in this embodiment, on the basis of the structure described in Embodiment 1, the plug part 1 also includes a tail buckle 4 that is fastened on the cable 2 at the plug end , after the pin 21 is inserted into the jack 131, the tail buckle 4 is fastened with the metal shell 11 to fix the cable 2 at the plug end, thereby preventing the cable connected with the plug part 1 from being loose and withdrawn.

Embodiment 3

[0032] Such as Figure 1 to Figure 5 As shown, a new type of high-performance high-voltage high-current connector shown in this embodiment, on the basis of the structure described in Embodiment 2, the plug part 1 also includes a waterproof ring 14, and the waterproof ring 14 is arranged in the access hole 121 Inner and sleeved on the plug-end cable 2 close to the inner side of the tail buckle 4 to realize a sealed structure and prevent moisture intrusion.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap