Device for automatically assembling vehicle lock torsion spring

An automatic assembly, torsion spring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to achieve mass production, low manual assembly efficiency, easy deformation of door lock torsion springs, etc., to meet automation requirements. The effect of running water production, saving labor costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

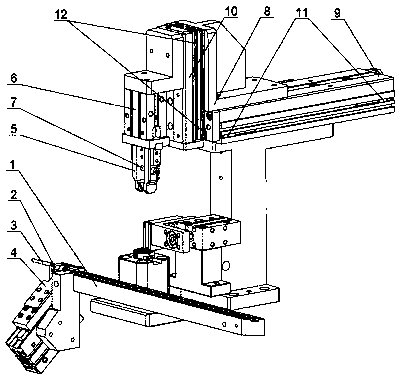

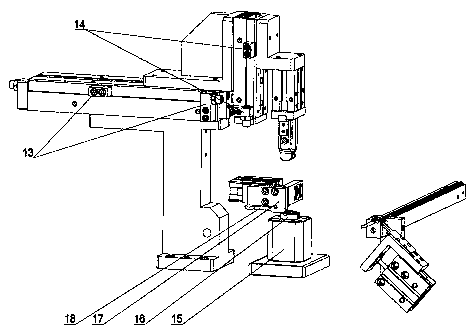

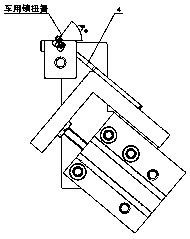

[0022] Example. A device for automatic assembly of a lock torsion spring for a vehicle, consisting of Figure 1-6 As shown, there is a door lock torsion spring direct vibration track 1, the end of the door lock torsion spring direct vibration track 1 is equipped with a torsion spring slideway end stopper 2, and a magnetic induction switch is arranged on the torsion spring slideway end stopper 2. 3. The torsion spring direct vibration track 1 on the side of the end block 2 of the torsion spring slideway is provided with a torsion spring turning block 4, and the upper side of the torsion spring turning block 4 is provided with a torsion spring clamp claw 5, and a torsion spring clamp claw 5 The top is connected with a jaw cylinder 6, and the jaw cylinder 6 is fixed on the moving device 8.

[0023] The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap