All-terrain chassis capable of freely switching crawler belts and Mecanum wheels

An all-terrain and crawler technology, applied to tracked vehicles, transportation and packaging, motor vehicles, etc., can solve the problem that the tracked chassis cannot move fast, achieve good frontal buffering effect, increase driving torque, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

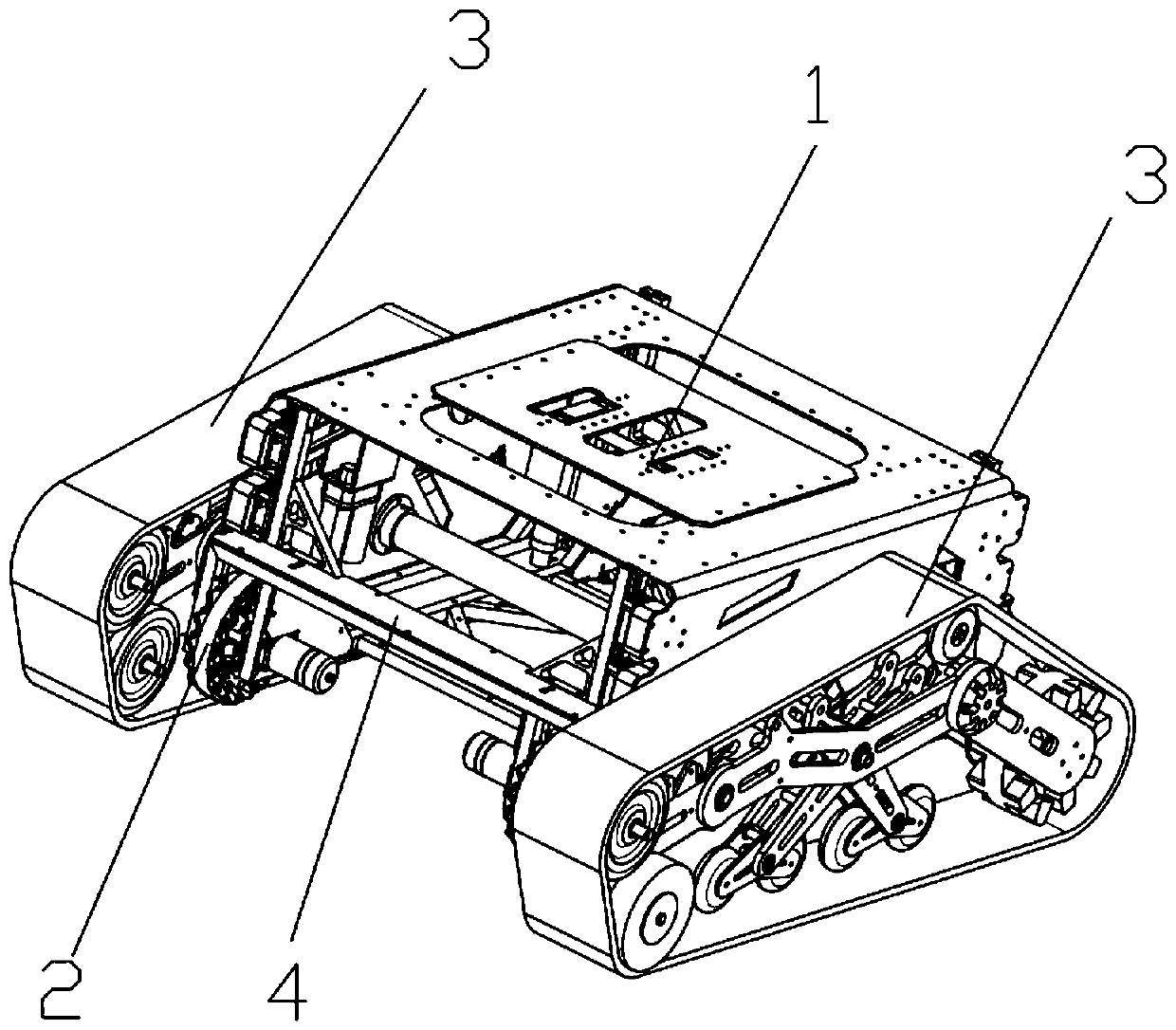

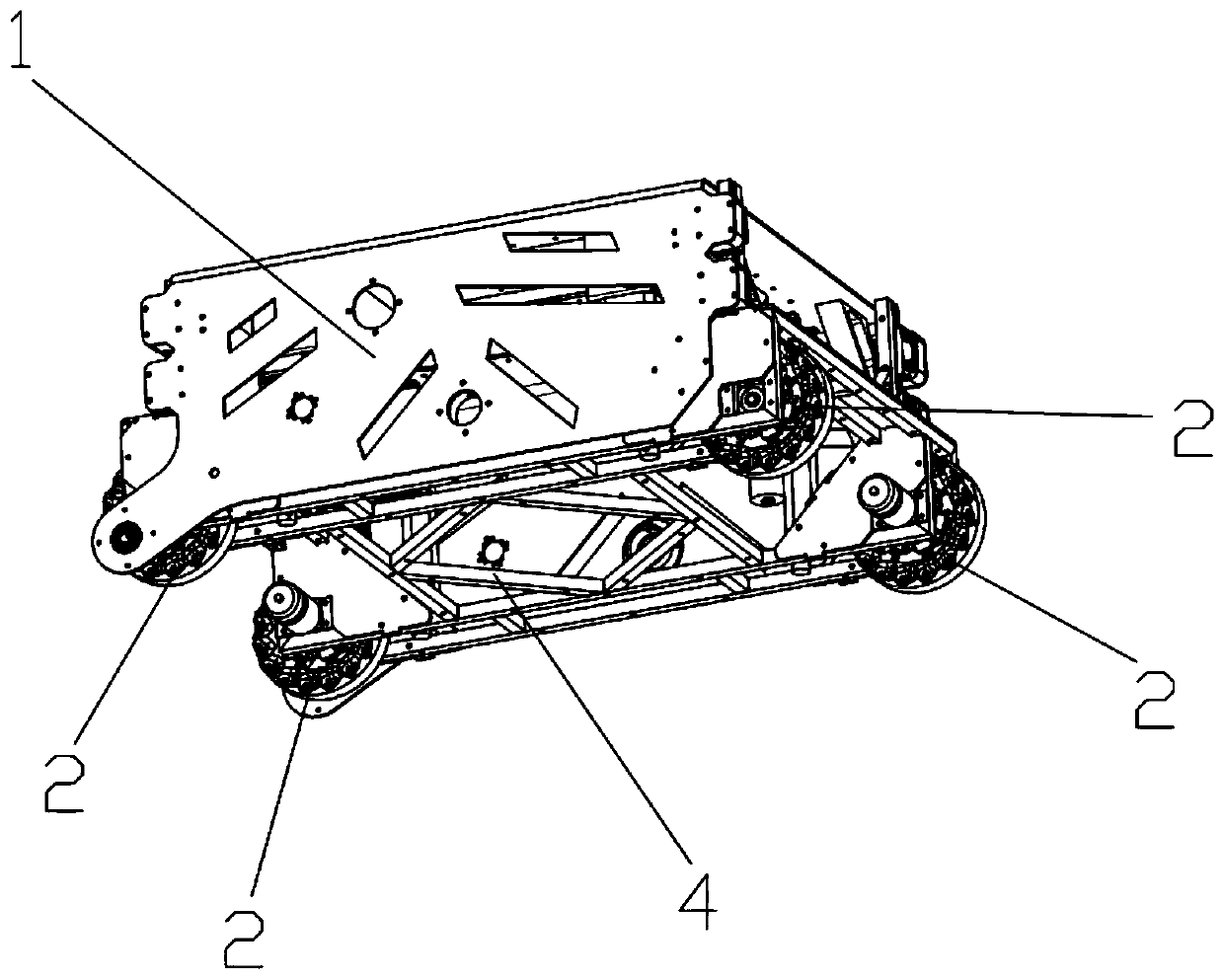

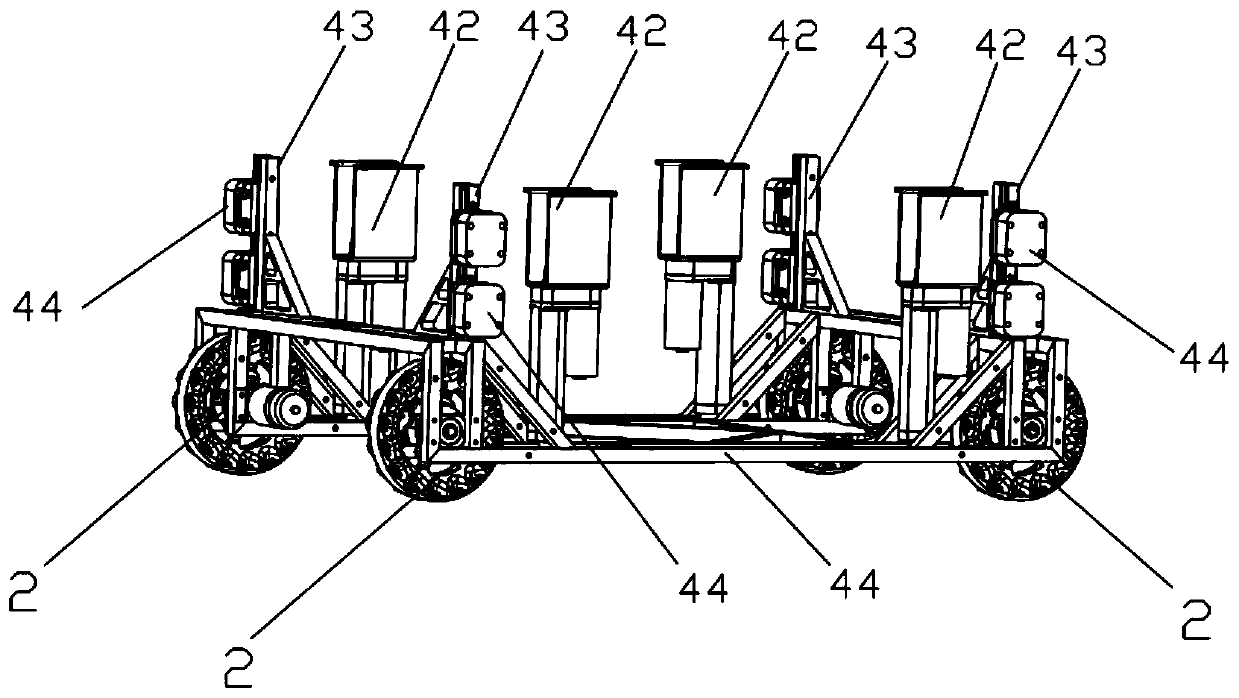

[0089] The structure of the all-terrain chassis that can freely switch between crawler tracks and mecanum wheels in this embodiment is as follows: Figures 1 to 22 Shown includes: car body 1, wheat wheel mechanism 2, crawler mechanism 3 and switching mechanism 4;

[0090] The crawler mechanism 3 is installed on both sides of the car body 1, and the crawler mechanism 3 can independently control the movement of the chassis in any direction;

[0091] The switching mechanism 4 is installed on the bottom of the car body 1, the wheat wheel mechanism 2 is installed on the switching mechanism 4, and the switching mechanism 4 can control the wheat wheel mechanism 2 to rise or fall, and the wheat wheel mechanism 2 can independently control the advancement of the chassis in any direction.

[0092] When the switching mechanism 4 drives the wheat wheel mechanism 2 to descend, the wheat wheel mechanism 2 supports the entire chassis upwards, so that the crawler mechanism 3 is lifted off the gro

Embodiment 2

[0134] Such as Figures 23 to 24 As shown, the all-terrain chassis that can freely switch between crawler tracks and mecanum wheels in this embodiment has the function of climbing stairs in addition to being able to freely switch through the wheat wheel mechanism 2 and the crawler mechanism 3 to adapt to all-terrain terrain;

[0135] The outer circle of crawler belt 31 is provided with the transverse bar 311 that is perpendicular to the circumferential direction of crawler belt 31, when crawler belt mechanism 3 advances to stair, because the outer circle common tangent of first anti-collision wheel 331 and second anti-collision wheel 332 and ground The horizontal line is at an angle of 60°, so the crawler belt 31 is also in a state of cutting and slanting relative to the steps. At this time, the crawler belt 31 will not slip parallel to the steps, and the horizontal bar 311 can hook the steps, so that the crawler belt mechanism 3 can complete the climbing of the steps. climb.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap