Anti-down-feather-fleeing production method for down quilt

A production method and a technology to be protected, which is applied in the production and application of household utensils and furniture covers, can solve the problems of three-dimensional down fleece and other problems, and achieve the effects of eliminating fleece, solving the phenomenon of fleece, and preventing fleeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

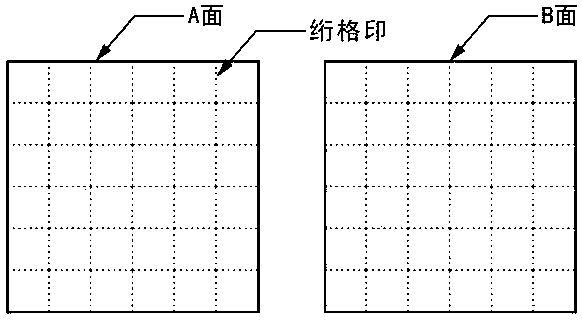

[0016] The technical scheme adopted by the present invention is as follows: Step 1 ironing the quilting grid: fabrics A and B are respectively the upper and lower layers of cut pieces, and the cut pieces are equally divided according to the size of the quilting grid, and the quilting line is ironed into a fold print with an iron;

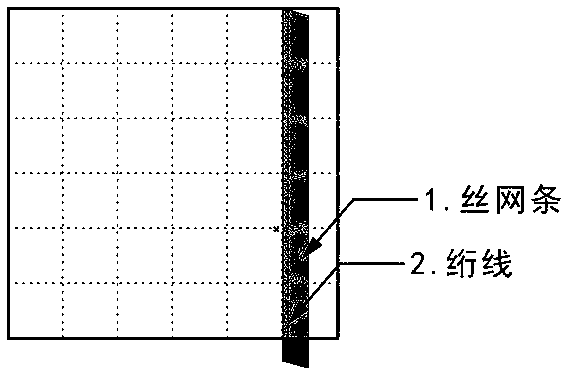

[0017] Step 2: Strips: Put the screen strip 1 under each crease of the cut piece, and the sewing machine will quilt the screen strip 1 with each grid of the cut surface to form a quilting line 2. Use the same method on both sides A and B. Quilted wire mesh strip 1;

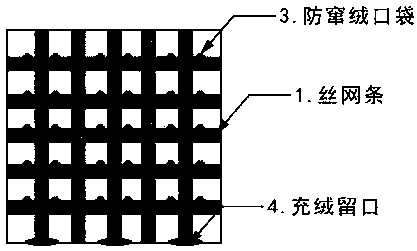

[0018] Step 3 Sewing and leaving the opening: Sewing the anti-fleece pocket cloth 3 at the intersection of the lining strip horizontally and longitudinally, sewing around A and B, leaving a filling opening 4 on the side corresponding to the down filling channel;

[0019] Step 4: Draw; draw the lining strips at the same position on both sides of A and B, draw the lining as shown in the figure, whe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap