Chemical water absorbent assisted sludge low-temperature drying box

A technology of water-absorbing agent and drying box, which is applied in dehydration/drying/concentrated sludge treatment, chemical instruments and methods, gas treatment, etc. It can solve the problems of uncontrollable moisture content of finished products, low energy consumption of solar drying, and odor generation and dust problems, to achieve the effects of wide applicability of sludge, improved heat exchange and dehumidification capacity, and less toxic problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

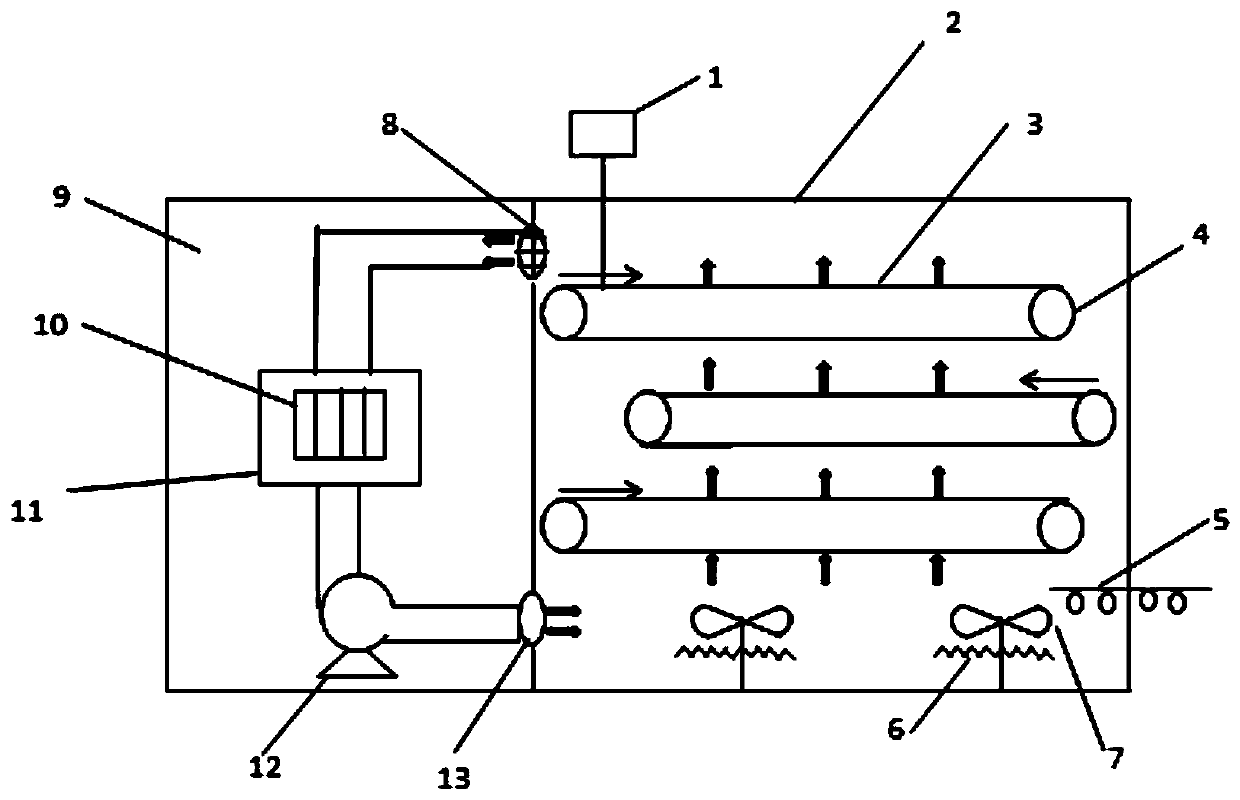

[0024] A chemical water-absorbing agent-assisted sludge low-temperature drying box, including a sludge film forming machine 1, an insulated box body 2, a three-layer mesh crawler belt 3, a dry sludge conveyor belt 5, a heater 6, a drying fan 7, and an air generator Heat pump 9, chemical water absorbent box 10 and ventilation pump 12.

[0025] Three layers of mesh crawlers 3 are layered inside the heat preservation box 2 from top

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap