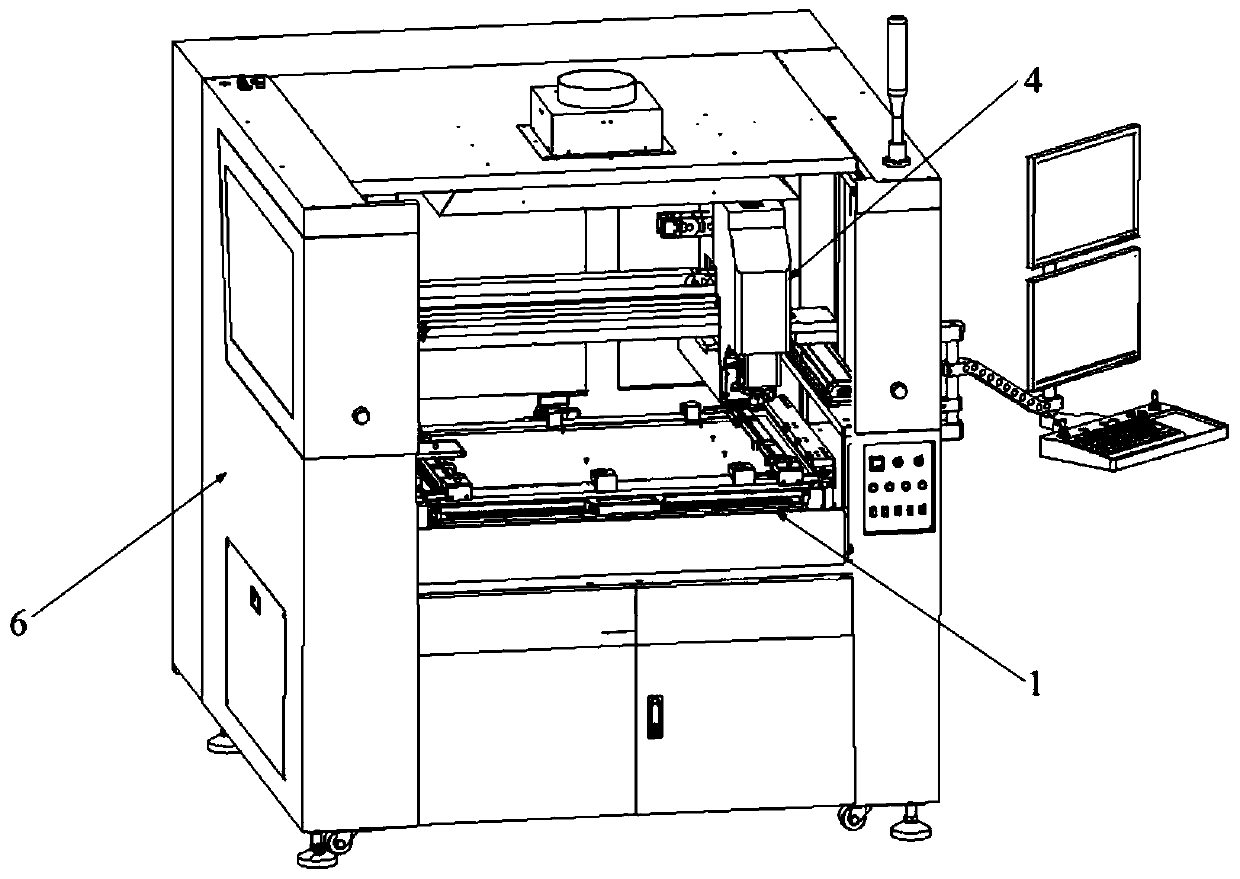

Large-temperature-zone multifunctional automatic BGA repair table

A multi-functional, rework station technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of inability to realize fixed-point heating, low degree of automation, and poor heating effect, and achieve compact structure, good heating effect, and improved safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below with reference to the drawings and specific embodiments.

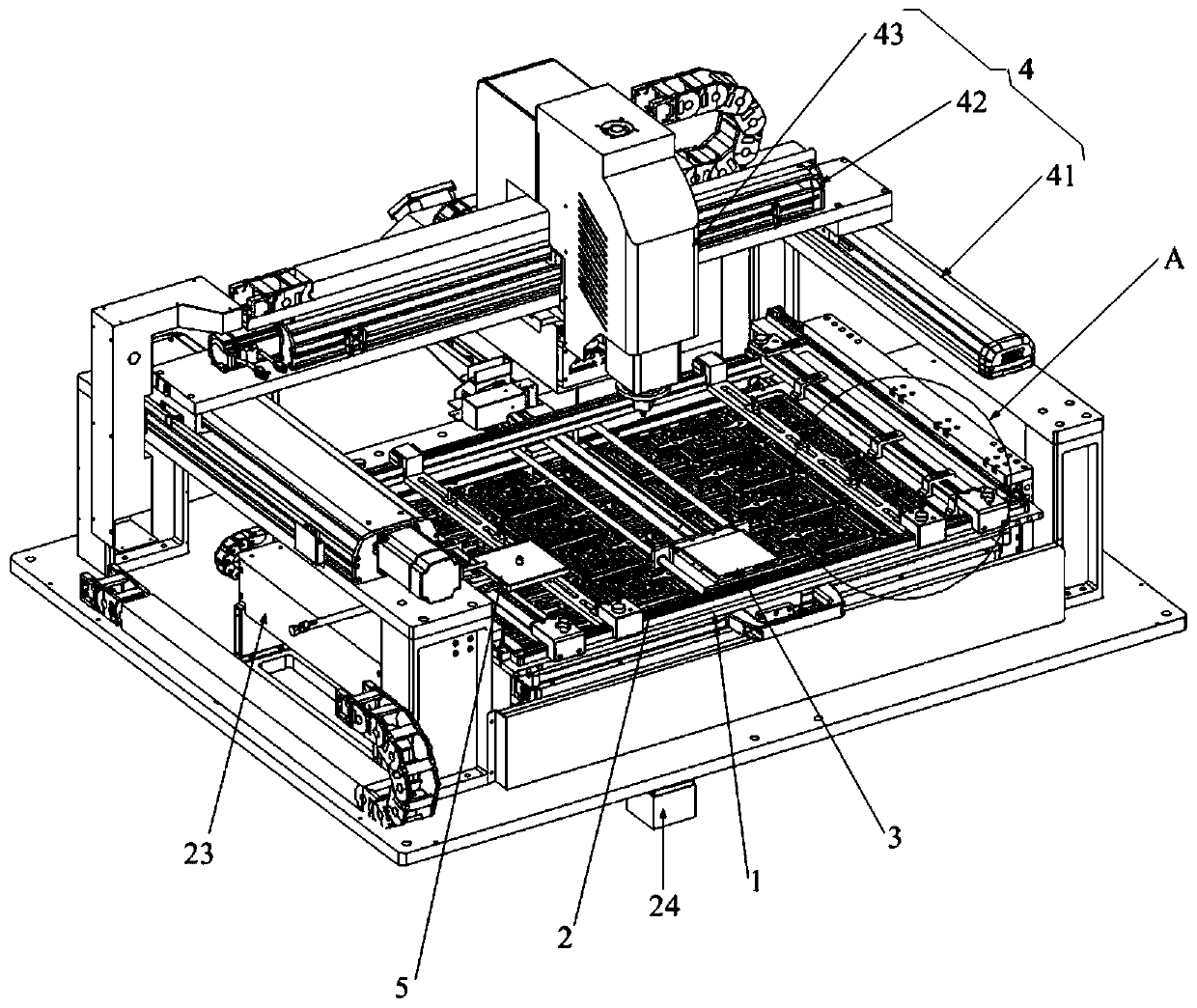

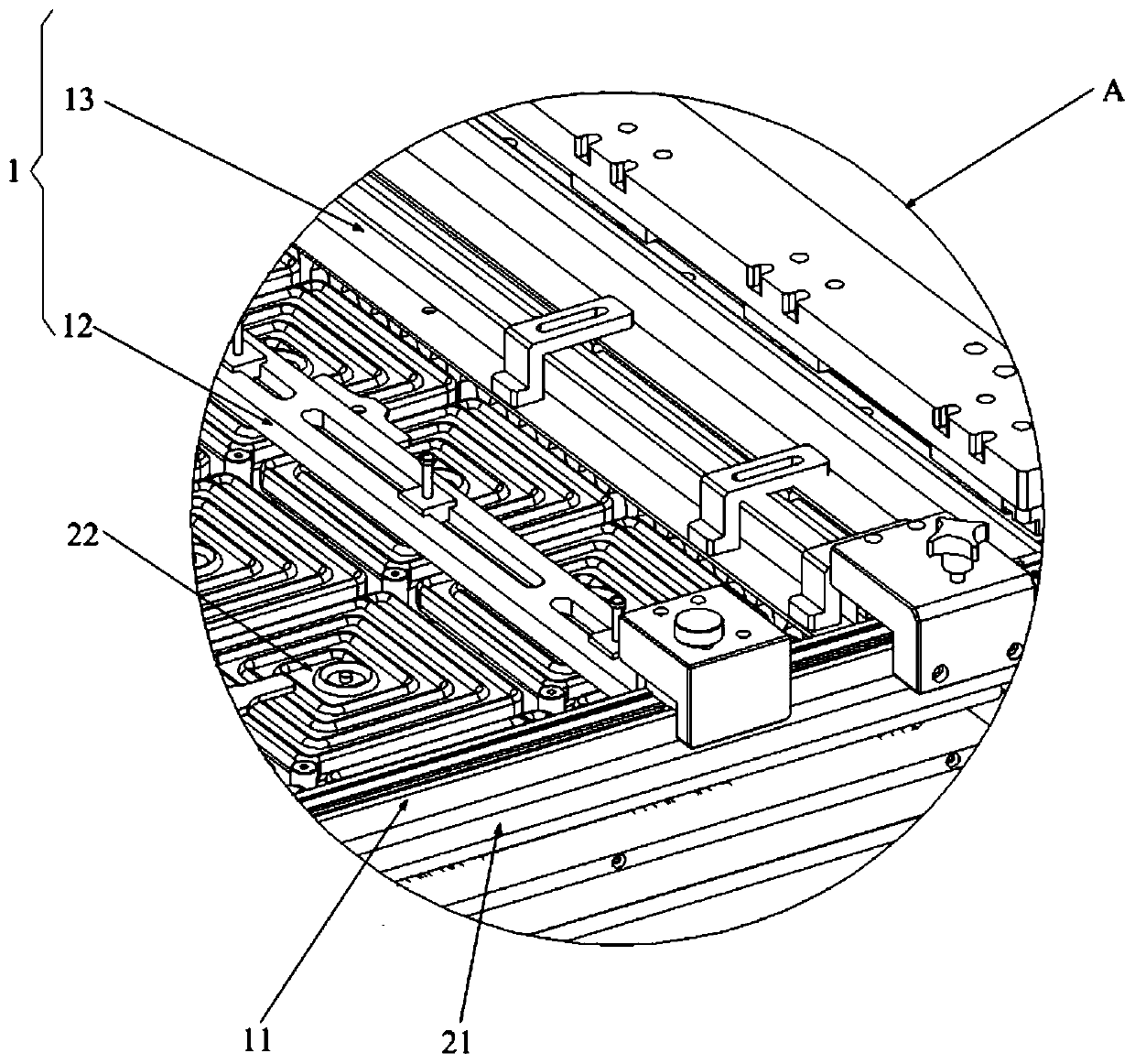

[0049] Reference Figure 1 to 6 As shown, the present invention provides a multi-functional automatic BGA rework station for large temperature zones, including a stage mechanism 1 for placing materials, a lower preheating mechanism arranged below the stage mechanism 1 for overall preheating of materials 2. The lower heating mechanism 3 arranged between the lower preheating mechanism 2 and the stage mechanism 1, the upper heating transfer mechanism 4 arranged above the stage mechanism 1, and the upper heating transfer mechanism arranged on the stage mechanism 1 4, the storage platform mechanism 5; the lower heating mechanism 3 and the upper heating transfer mechanism 4 are used to heat the bottom and top of the material at fixed points, and the upper heating transfer mechanism 4 is also used to repair the material. The components are transferred to the storage pla

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap