Virtual assembly method and device, equipment and medium

A virtual assembly and equipment technology, applied in the aerospace field, can solve problems such as inability to achieve registration effects, and achieve the effect of meeting assembly error requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

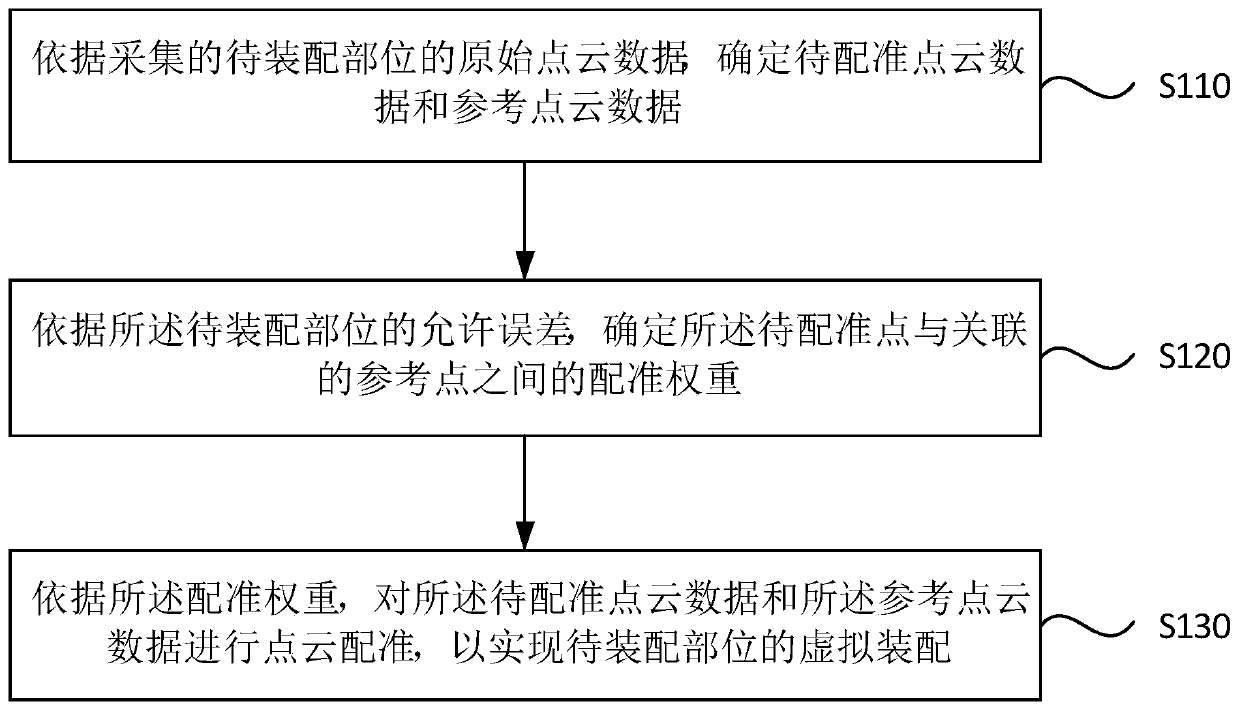

[0026] figure 1 It is a flow chart of a virtual assembly method provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of virtual assembly of equipment. Typically, this method can be applied to virtual assembly of equipment in the aerospace field. The method can be performed by a virtual assembly device.

[0027] see figure 1 , the method specifically includes the following steps:

[0028] Step 110, according to the collected original point cloud data of the part to be assembled, determine the point cloud data to be registered and the reference point cloud data.

[0029] Among them, point cloud data refers to a set of vectors in a three-dimensional coordinate system. These vectors are usually expressed in the form of X, Y, Z three-dimensional coordinates, and are generally mainly used to represent the outer surface shape of an object. Not only that, in addition to the geometric position information represented by (X, Y, Z), point clo

Embodiment 2

[0065] Figure 5 It is a schematic structural diagram of a virtual assembly device provided by an embodiment of the present invention. refer to Figure 5 , the device may specifically include: a point cloud data determination module 210 , a registration weight determination module 220 and a registration module 230 .

[0066] Wherein, the point cloud data determination module 210 is used to determine the point cloud data to be registered and the reference point cloud data according to the collected original point cloud data of the part to be assembled;

[0067] A registration weight determination module 220, configured to determine the registration weight between the to-be-registered point and the associated reference point according to the allowable error of the to-be-assembled part;

[0068] The registration module 230 is configured to perform point cloud registration on the point cloud data to be registered and the reference point cloud data according to the registration weig

Embodiment 3

[0077] Image 6 It is a schematic structural diagram of a device provided by Embodiment 3 of the present invention. Image 6 A block diagram of an exemplary device 12 suitable for use in implementing embodiments of the invention is shown. Image 6 The shown device 12 is only an example and should not impose any limitation on the functions and scope of use of the embodiments of the present invention.

[0078] Such as Image 6 As shown, device 12 takes the form of a general purpose computing device. Components of device 12 may include, but are not limited to: one or more processors or processing units 16, system memory 28, bus 18 connecting various system components including system memory 28 and processing unit 16.

[0079] Bus 18 represents one or more of several types of bus structures, including a memory bus or memory controller, a peripheral bus, an accelerated graphics port, a processor, or a local bus using any of a variety of bus structures. These architectures include,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap