Power-assisted turnover type sea salt collecting and scraping equipment

A flip-type, sea-salt technology, applied in loading/unloading, transportation and packaging, alkali metal chloride, etc., can solve the problems of laborious and troublesome pulling back wooden boards, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

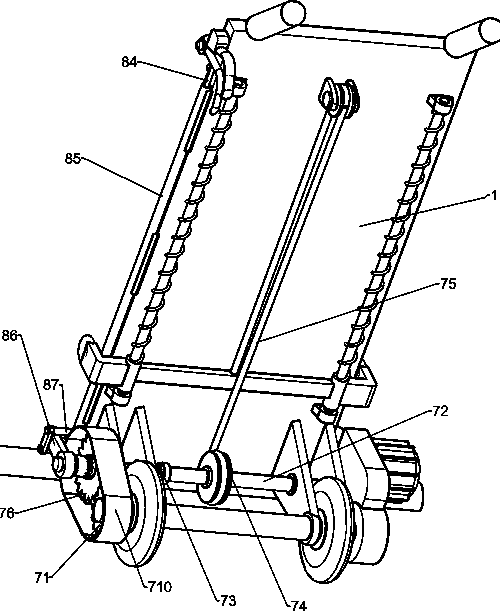

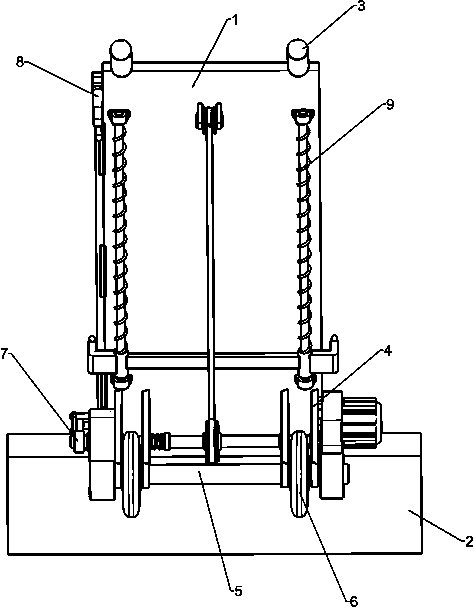

[0050] A power-assisted flip-type sea salt scraping device, such as Figure 1-6 As shown, it includes a push plate 1, a scraper 2, a handle 3, a leg 4, a rotating shaft 5, a roller 6, a guide mechanism 9, a salt collecting plate 12 and a tractor 121, and the rear side of the salt collecting plate 12 is provided with a tractor 121, Traction wire is wound on the tractor 121, push plate 1 is placed on the salt collecting plate 12, scraper 2 is arranged on the lower part of push plate 1, handle 3 is symmetrically arranged on the left and right sides of the upper part of push plate 1, and the left and right sides of the front side of push plate 1 are Both sides are symmetrically provided with support legs 4, and there are two support legs 4 on the left and right sides, and the rotating shaft 5 is connected between the supporting legs 4, the left and right sides of the rotating shaft 5 are provided with rollers 6, and the front part of the push plate 1 is provided with a guiding mechani

Embodiment 2

[0053] On the basis of Example 1, such as Figure 1-6 As shown, the guide mechanism 9 includes a guide rod 91, a guide sleeve 92, a connecting plate 93, a connecting buckle 94 and a second spring 95, and a pair of guide sleeves 92 are symmetrically arranged on the left and right sides of the front portion of the push plate 1, and every two guide sleeves 92 is connected with guide rod 91, and guide rod 91 is push plate 1 lengthwise installations, and guide rod 91 is slidably connected with connecting plate 93, and connecting plate 93 left and right sides are symmetrically provided with connecting buckle 94, and connecting buckle 94 and traction A second spring 95 is connected between the guide sleeve 92 on the upper side of the push plate 1 and the connecting plate 93, and the second spring 95 is sleeved on the guide rod 91.

[0054] When people need to scrape sea salt, they connect the traction line to the connecting buckle 94, and then they push the push plate 1 and turn on the

Embodiment 3

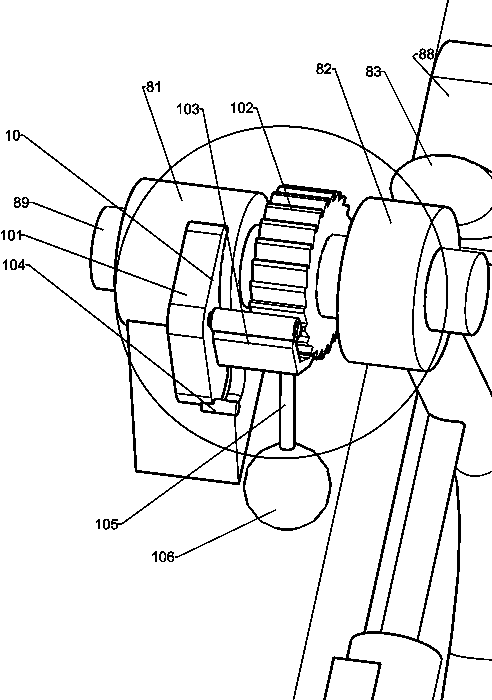

[0058] On the basis of Example 2, such as Figure 1-6 As shown, an automatic reset mechanism 10 is also included, and the automatic reset mechanism 10 includes a mounting plate 101, a ratchet 102, a pawl 103, a shrapnel 104, a pole 105 and a weight ball 106, and the rear part of the hinged seat 81 is provided with a mounting plate 101 , the left side of the mounting plate 101 is provided with a ratchet 103, the lower part of the left side of the mounting plate 101 is connected to the rear part of the ratchet 103 with a shrapnel 104, the lower part of the ratchet 103 is provided with a pole 105, and the bottom of the pole 105 is provided with a counterweight ball 106, A ratchet 102 is arranged in the middle of the connecting column 89 , and the ratchet 102 cooperates with the ratchet 103 .

[0059] When people firmly hold the rocker 82 and the arc rod 83, the rocker 82 will drive the connecting column 89 to rotate forward, and the forward rotation of the connecting column 89 will

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap