Lock cylinder steel ball press riveting equipment

A technology of steel balls and lock cylinders, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of beating on artificial hands, insufficient beating of steel balls, and low assembly efficiency, so as to reduce labor force, reduce manpower, and develop low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Embodiment 1:

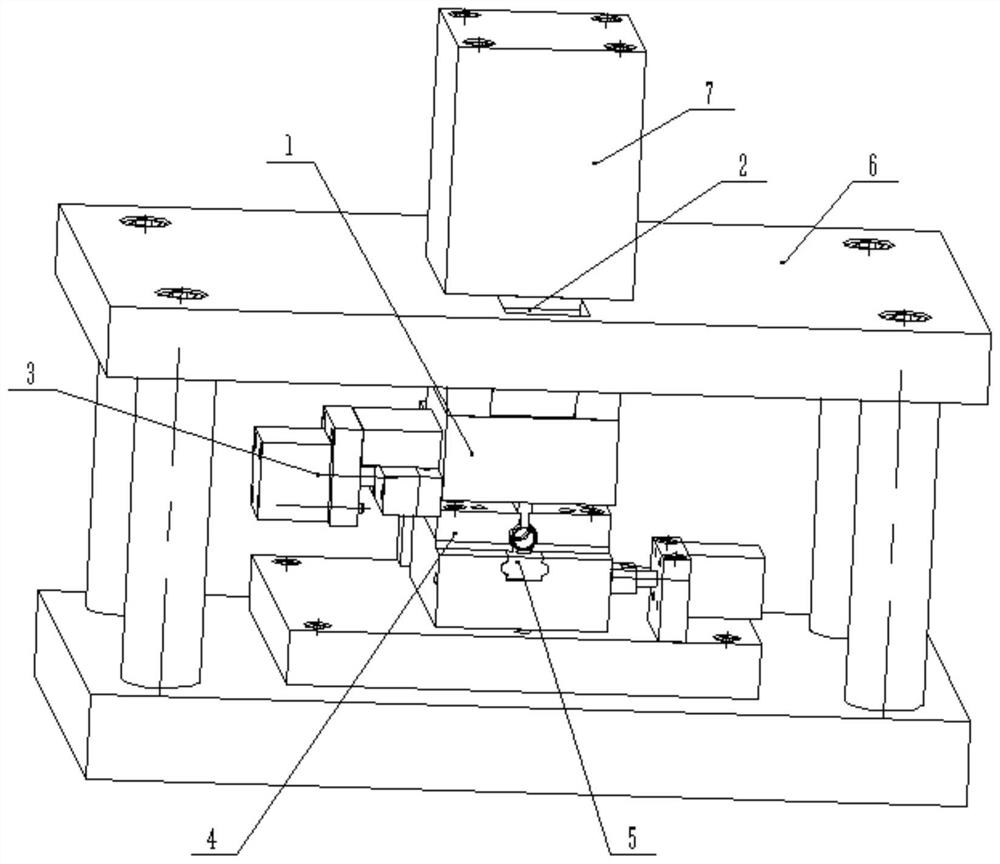

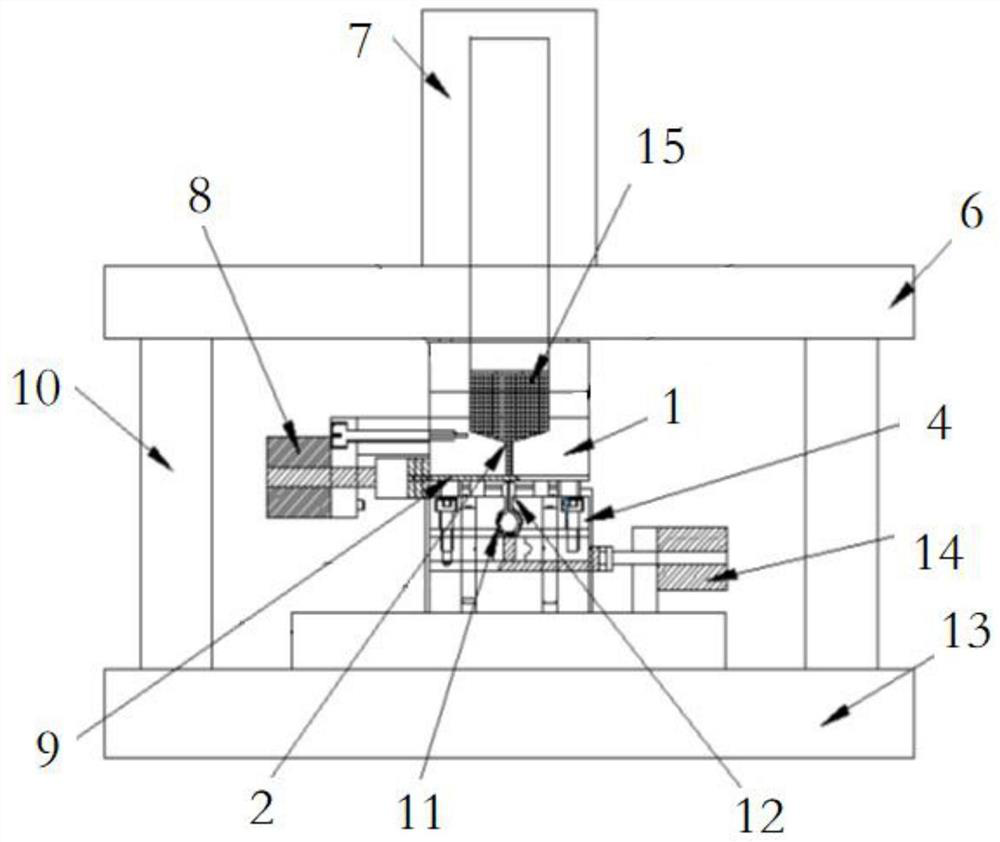

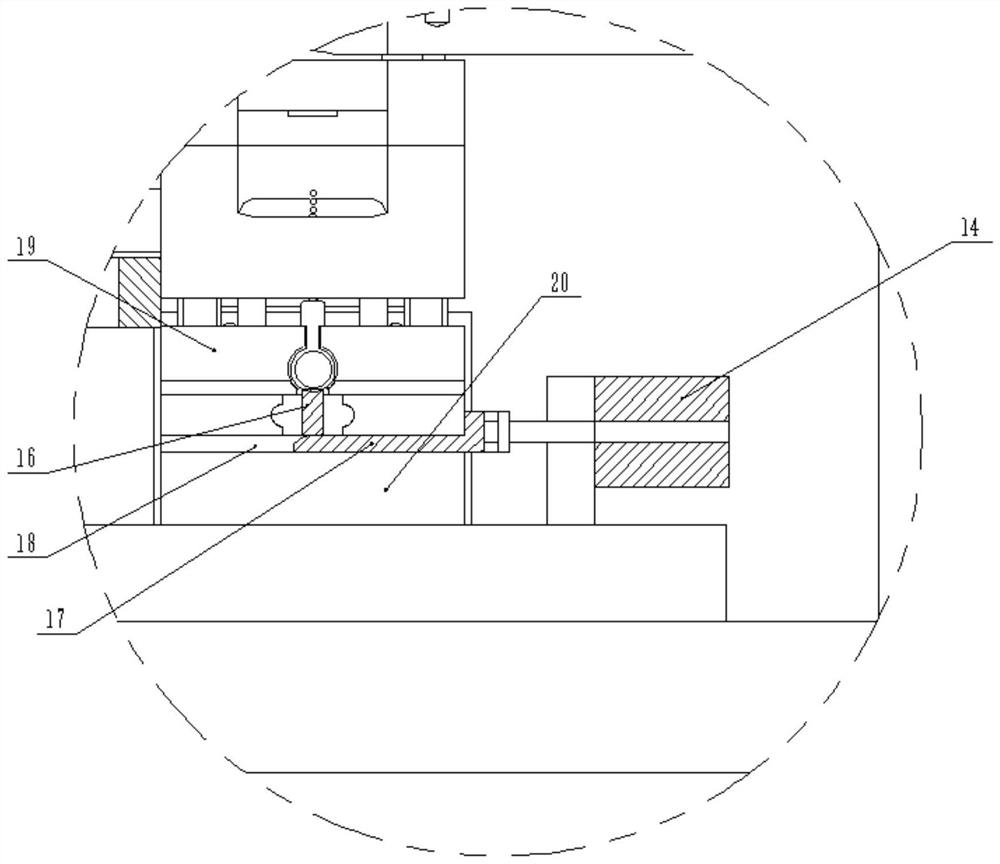

[0029] like Figure 1-7 As shown, a lock core steel ball pressure riveting equipment includes: an upper die assembly and a lower die assembly that cooperate with each other, the upper die assembly includes an upper die fixing seat 6 and an upper die head 7, the upper die head 7 is arranged on the upper side of the upper die fixing seat 6 , the upper template 1 is connected to the lower side of the upper die fixing seat 6 , and the inlet end of the hopper 2 is arranged through the upper die fixing seat 6 . When in use, the upper die head 7 is connected with the punch press to transmit the power of the punch press to the upper die assembly to complete the riveting.

[0030] The lower part of the upper die assembly is connected with an upper die plate 1 and a hopper 2, the hopper 2 is built in the upper die plate 1, and the inlet end of the hopper 2 is arranged through the upper die component, which is convenient for putting steel balls 15, and the hopper 2

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap