Handheld cutting equipment for processing willow artware

A kind of wood handicraft, the technique of using hands, applied in the field of willow wood handicraft, can solve the problems of manual scribing, height can not be adjusted, affect the use of cutting equipment, etc., to achieve the effect of simple adjustment and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

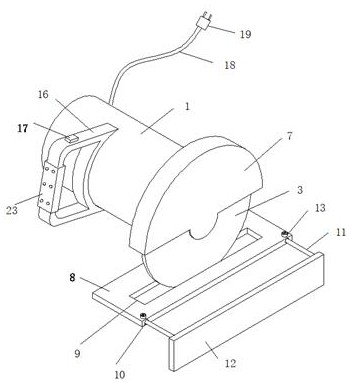

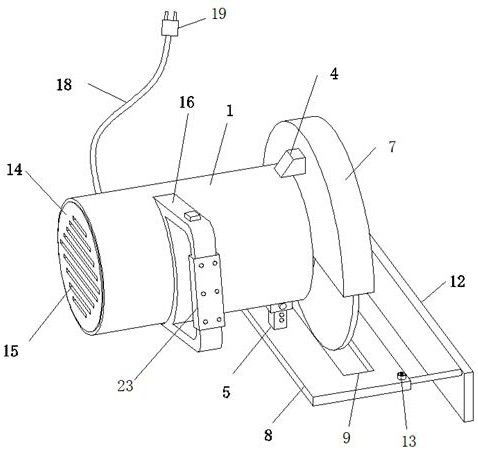

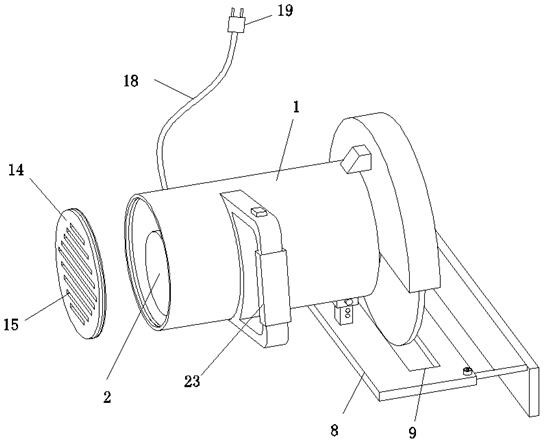

Image

Examples

Embodiment 2

[0041] Embodiment 2 is on the basis of embodiment 1, as Image 6 and Figure 7 As shown, the outer walls of the two guide posts 11 are provided with a scale line 20 , and the value of the starting point of the scale line 20 is the horizontal distance from the right edge of the translation plate 8 to the cutting piece 3 .

[0042] During the use of the present embodiment, the rightmost display of the guide post 11 is the starting point, and the cutting width is read at the circular hole 10 provided on the right side wall of the translation plate 8, so as to facilitate accurate adjustment and cutting of wood with different widths. piece.

Embodiment 3

[0044] Embodiment 3 is on the basis of embodiment 2, as Figure 8 As shown, the upper end surface of the protective cover 7 is provided with an arc-shaped hole 21, and the arc-shaped hole 21 communicates with the inside of the protective cover 7. One end of the arc-shaped hole 21 is also hinged with an arc-shaped cover plate 22, and the other end of the arc-shaped hole 21 One end is fixed to the arc-shaped cover plate 22 through a magnetic block.

[0045] In the present embodiment, the arc cover 22 can be closed during use, so that the top of the protective cover 7 is in a sealed state, which can effectively prevent wood chips from flying out; after use, the arc cover 22 can be opened and the fan can be used to The sawdust inside the protective cover 7 is cleaned, and the inside of the protective cover 7 can be cleaned without dismantling the entire protective cover 7, which is easy to operate and strong in practicability.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap