Mold closing device and mold closing method for three-post insulator mold

A mold clamping device and insulator technology, which is applied in the field of mold clamping device for three-pillar insulator molds, can solve problems such as residual metal foreign matter and bad insulators, and achieve the effects of preventing movement, stable support, and convenient hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

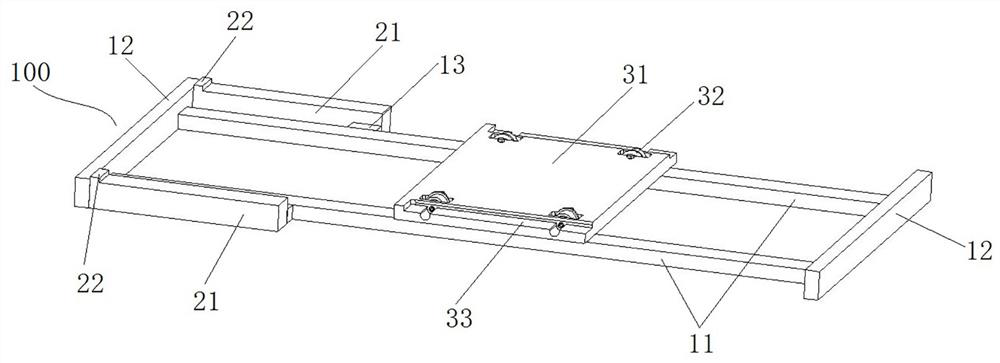

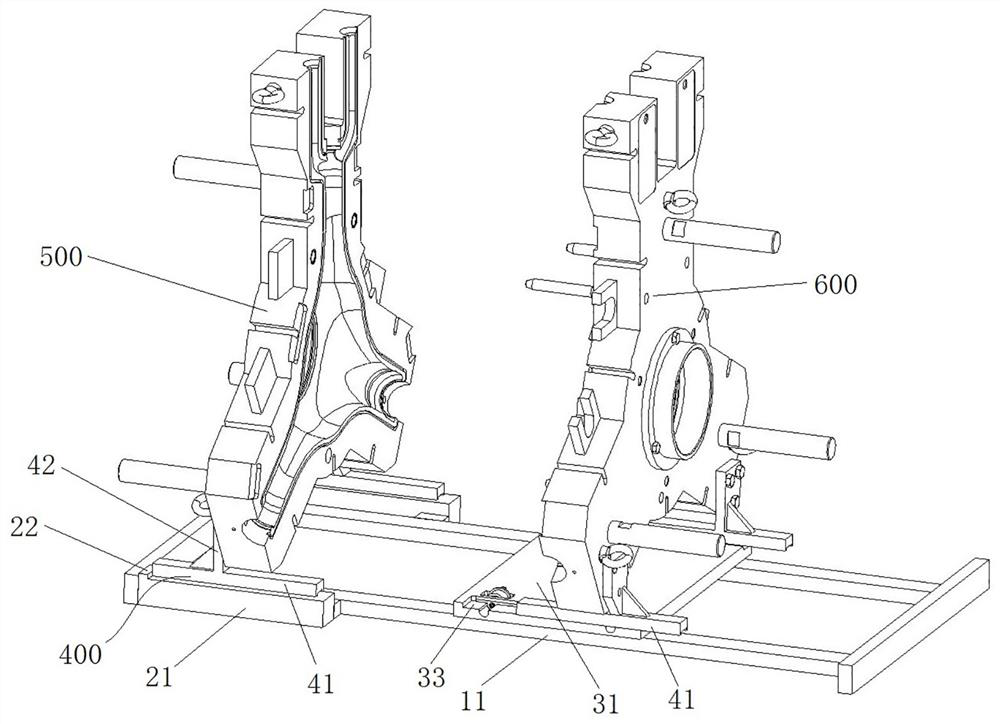

[0040] Such as figure 1 and figure 2 As shown, the clamping device includes a support frame 100, on which the positioning end half-mold support table 21 is fixedly installed, and the movable end half-mold support table 31 is equipped with a movable end half-mold support table 31 for guiding and moving along the left and right directions, and the movable end half-mold support table 31 The movement realizes the splitting and closing of the half-mold 500 at the positioning end and the half-mold 600 at the movable end.

[0041] The support frame 100 includes two guide rails 11 extending in parallel. The guide rails 11 extend left and right. The support frame 100 also includes an end connection 12 connecting the left end and the right end of the two guide rails 11. The end connection 12 is a column or a plate to strengthen the support. The overall strength of the frame 100.

[0042] Such as figure 1 As shown, there are two half-mold support platforms 21 at the positioning end, and

Embodiment 1

[0058] In Embodiment 1, the support frame includes two guide rails extending in parallel, and the half-mold support platform at the movable end realizes guiding cooperation with the guide rails through track wheels. In this embodiment, a dovetail groove extending in the left and right direction is provided at the bottom of the mold half support platform at the movable end, and the guide rail is used in conjunction with the dovetail groove to guide the mold support platform half at the movable end. Or, the supporting frame can be a plate body, a dovetail groove is provided on the plate body, and guide rails are fixedly installed at the bottom of the half-mould supporting platform at the movable end.

specific Embodiment 3

[0060] In Embodiment 1, the mold clamping device includes legs, and the legs are fixedly installed on the mold half when in use. In this embodiment, when the lower end of the half-mold has a certain width and can be placed stably, the supporting legs can be canceled and the half-mold can be directly placed on the support platform. After the support leg is cancelled, the stop boss and the positioning part directly cooperate with the half mold. It should be noted that regardless of whether there are legs or not, it is necessary to ensure that the two mold halves are kept at the same level to achieve a centered arrangement.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap