Sewage pump and sewage discharge system for sewage treatment at shield of tunnel boring machine

A technology for tunnel boring machines and sewage treatment, which is applied to the components of pumping devices for elastic fluids, pumps for special fluids, pumps, etc. , insufficient sewage discharge capacity, etc., to achieve the effect of reducing the initial procurement cost, strong power, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

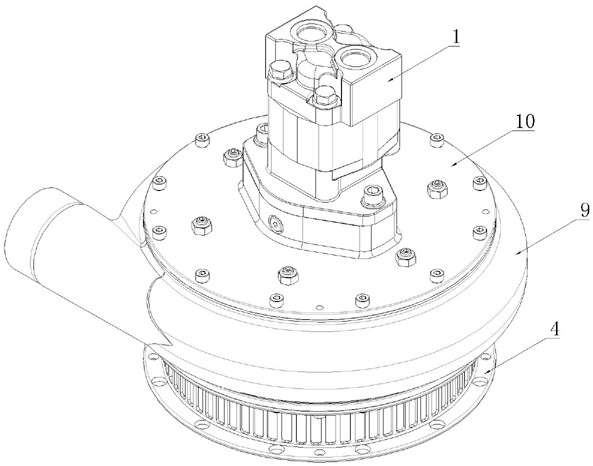

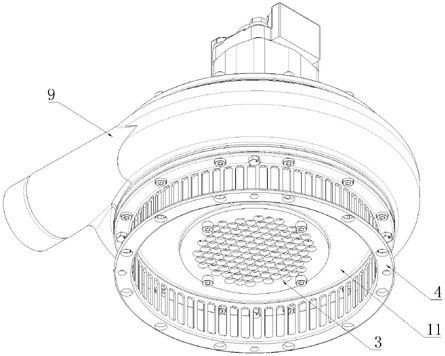

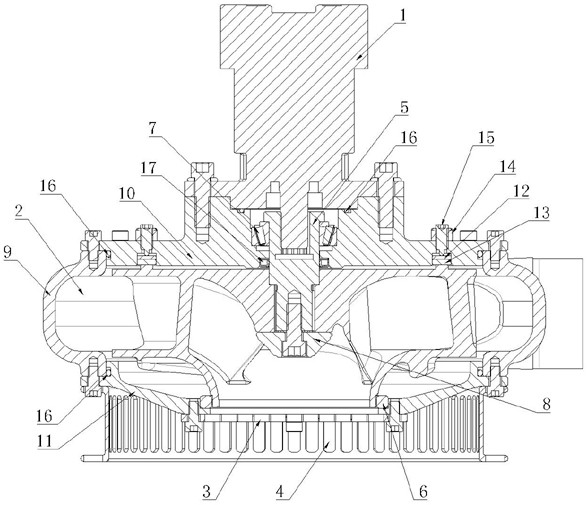

[0032] This embodiment provides a sewage pump for sewage treatment at the shield of the tunnel boring machine, including a hydraulic motor 1, a casing, an impeller 2, a filter screen 3 and a filter screen support 4; the casing is a volute structure, and the bottom surface is provided with a suction pump The liquid port is provided with a liquid discharge port on the side; the impeller 2 is installed in the casing, and the center is provided with an inner spline hole 2.1; the hydraulic motor 1 is fixed on the top surface of the casing, and the output shaft is fixed with a spline shaft 5 and a spline shaft 5 The outer spline section of the impeller 2 cooperates with the inner spline hole 2.1 of the impeller 2; the filter screen 3 is arranged on the liquid suction port; the filter screen support 4 is an annular support provided with filter holes on the side wall, and is fixed around the liquid suction port.

[0033] The sewage pump adopts hydraulic drive, which can provide stronger p

Embodiment 2

[0042] This embodiment provides a sewage system for sewage treatment at the shield of the tunnel boring machine, including a hydraulic pump station and the above-mentioned sewage pump for sewage treatment at the shield of the tunnel boring machine; the hydraulic pump station includes an oil tank 18, an oil pump 19, Motor 20, speed regulating valve 21 and sequence valve 22; Oil pump 19 is driven by motor 20, and oil inlet is connected with fuel tank 18, and oil outlet is connected with the oil inlet of speed regulating valve 21; The working oil port of speed regulating valve 21 is connected with The oil inlet of the hydraulic motor 1 is connected; the working oil port of the hydraulic motor 1 is connected with the oil inlet of the sequence valve 22, and the oil return port is connected with the oil tank 18; the oil outlet of the sequence valve 22 is connected with the oil tank 18. The speed regulating valve 21 has two modes of manual and electric control, and the electric control m

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap