Spiral welded pipe forming position pipe diameter perimeter monitoring system

A spiral welded pipe and monitoring system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as the inability to adjust the position of the high-speed laser rangefinder and the imperfect monitoring system of the pipe diameter and perimeter, and achieve fast and accurate measurement , The effect of fast and accurate positioning and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

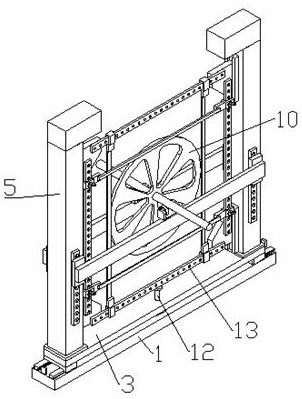

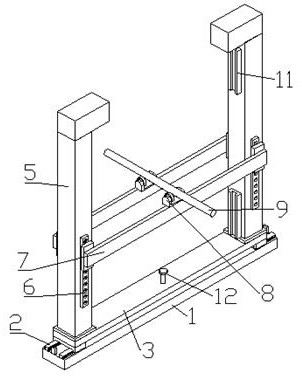

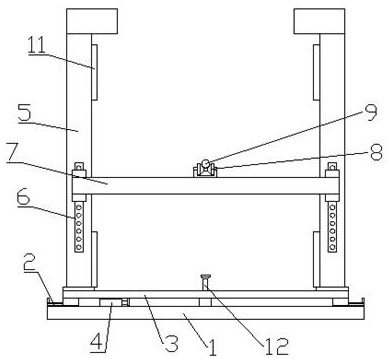

[0015] Such as Figure 1-4 As shown, a spiral welded pipe forming position pipe diameter circumference monitoring system, including base plate 1, horizontal slide rail 2, sliding base plate 3, horizontal adjustment electric cylinder 4, column 5, mounting frame slide rail 6, mounting frame 7, supporting wheels 8. Central axis 9, calibration plate 10, inner frame chute 11, up and down adjustment electric cylinder 12, inner frame 13, slide rails 2 are fixed on the top and bottom of the bottom plate 1, and the sliding bottom plate 3 adjusts the electric cylinder 4 horizontally through the bottom Sliding along the left and right directions of the slide rail 2, the left and right sides of the top of the sliding base plate 3 are vertically fixed with columns 5, and the vertical mounting frame slide rails 6 are respectively fixed on the front and rear...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap