Machine vision-based automatic workpiece sorting method and system

A machine vision and automatic sorting technology, applied in sorting, instruments, image analysis, etc., can solve problems such as inability to accurately reflect the conversion relationship between the camera coordinate system and the robot coordinate system, sorting failure, etc., and improve the sorting accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

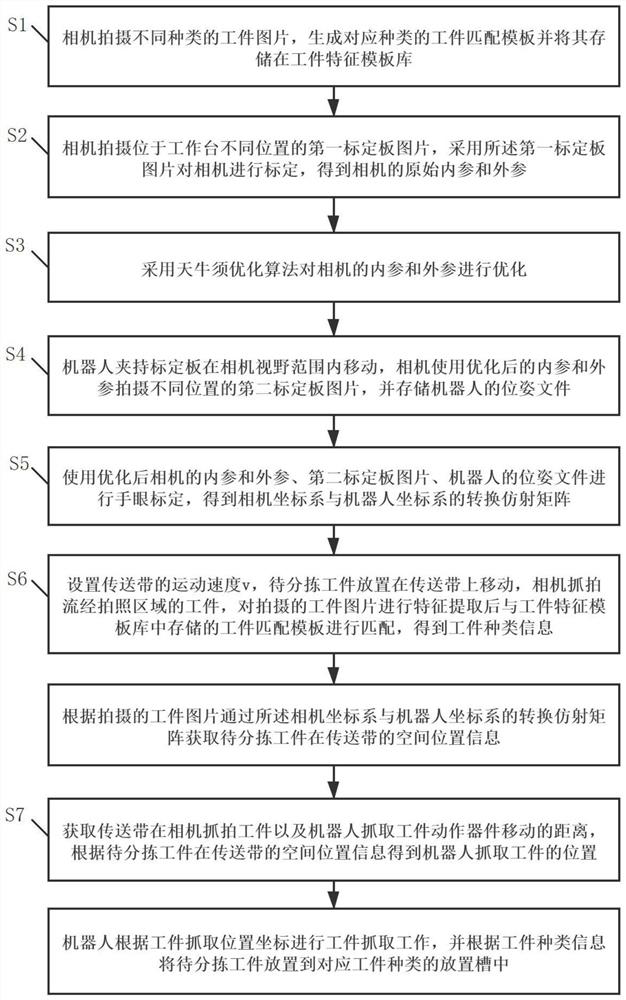

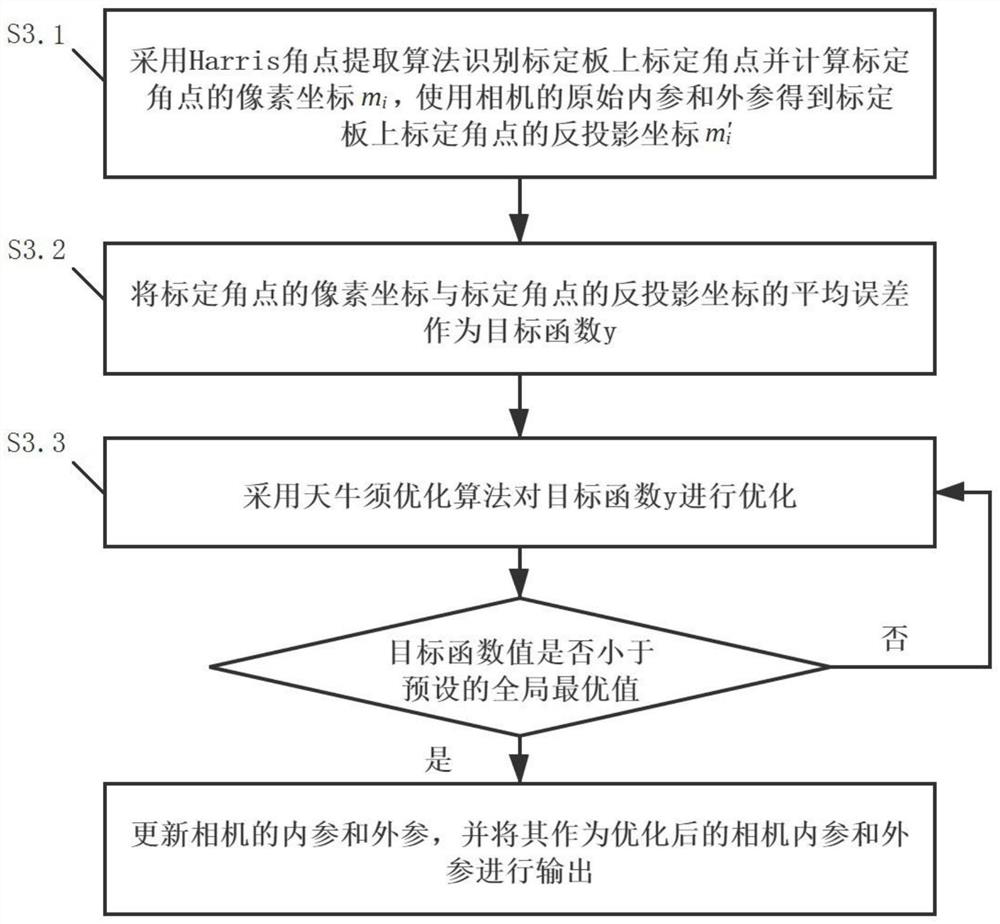

[0063] This embodiment proposes a method for automatic sorting of workpieces based on machine vision, comprising the following steps:

[0064] S1: The camera takes pictures of different types of workpieces, generates corresponding types of workpiece matching templates and stores them in the workpiece feature template library.

[0065] In this step, the weighted average filtering algorithm is used to preprocess the captured workpiece pictures to improve the quality of the workpiece pictures, and then extract the edge contour shape information of the workpieces in the pictures, and generate different types of workpiece matching templates, and the workpieces Matching templates are stored in the workpiece feature template library.

[0066] Among them, the weight in the weighted average filtering algorithm is the reciprocal of the gray gradient, and its expression formula is as follows:

[0067]

[0068]

[0069] d(i+k,j+l)=(|f(i+k,j+l)-f(i,j)|+1) -1 ,(k,l)≠(0,0)

[0070] In

Embodiment 2

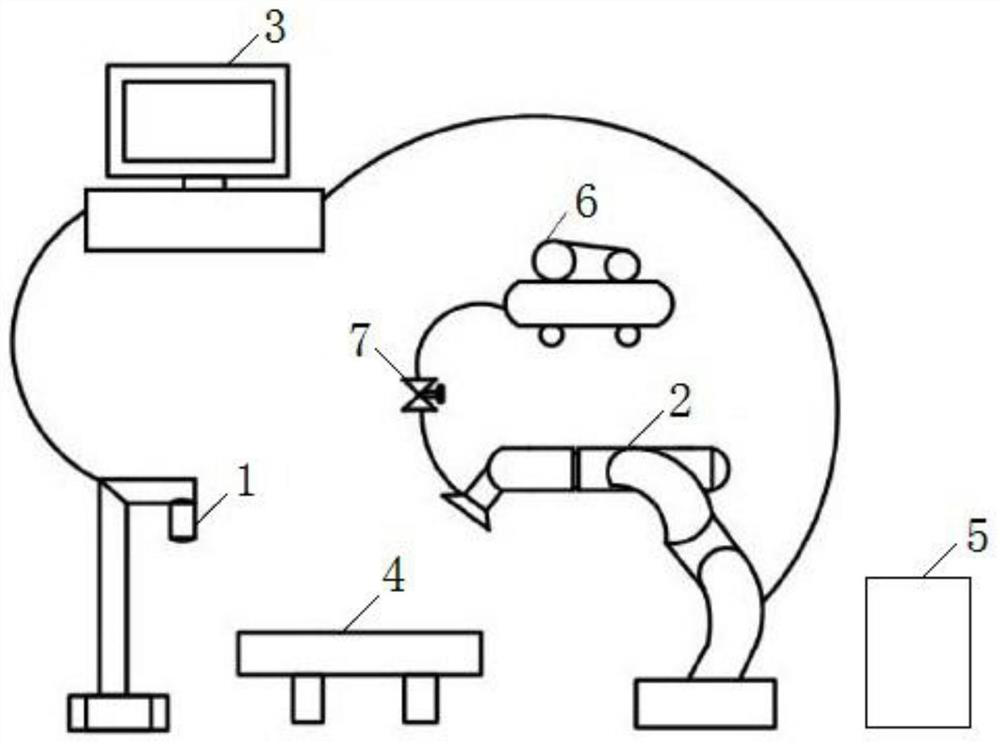

[0121] This embodiment proposes an automatic workpiece sorting system based on machine vision, and applies the automatic workpiece sorting method based on machine vision proposed in Embodiment 1. Such as image 3 Shown is a schematic structural view of the automatic workpiece sorting system based on machine vision in this embodiment.

[0122] The automatic workpiece sorting system based on machine vision proposed in this embodiment includes a camera 1, a sorting robot 2, a host computer 3, a workbench 4 and a placement slot 5, wherein:

[0123] The camera 1 is placed in the shooting area on one side of the workbench 4, and the sorting robot 2 is placed in the grabbing area on the other side of the workbench 4;

[0124] A conveyor belt is arranged on the workbench 4, and the conveyor belt is used to transmit different types of workpieces to the shooting area and the grabbing area;

[0125] The upper computer 3 classifies the workpiece types according to the workpiece photos take

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap