Statistical analysis method for determining sampling points of batch copper anode slime materials

A technology of statistical analysis and copper anode slime, which is applied in the field of statistical analysis to determine the number of sampling points for batches of copper anode slime materials, which can solve the problems of uncertain matrix composition, complex copper anode slime composition, and large quality fluctuation range, and achieve guaranteed representativeness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

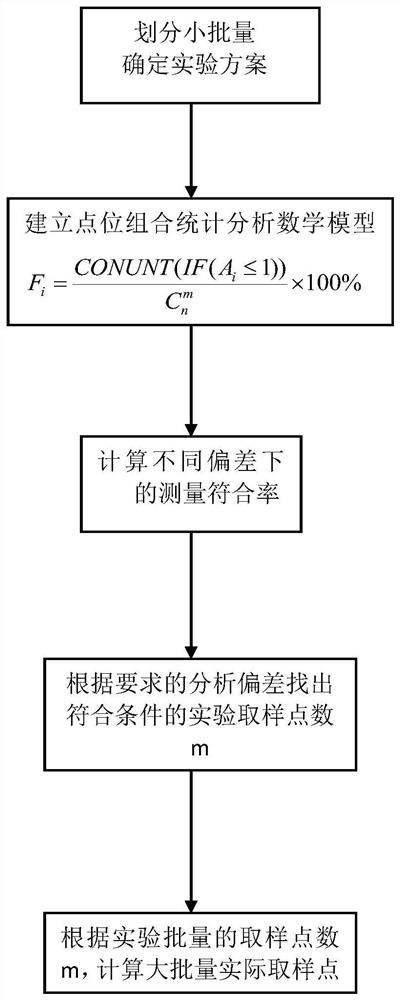

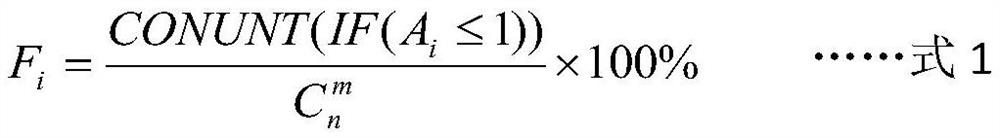

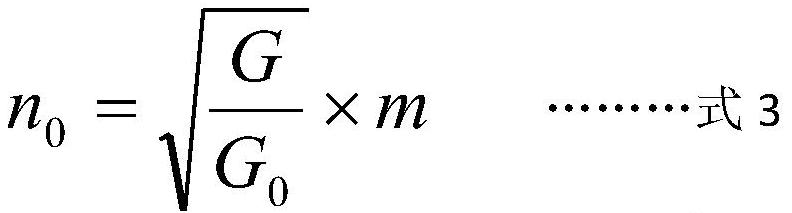

[0036] The statistical analysis method for determining the number of sampling points for batches of copper anode slime materials is based on the expensive value of copper anode slime materials, taking into account the inspection needs of material handover and trade settlement, and establishing corresponding levels according to different analysis deviation requirements and general measurement deviation requirements The statistical analysis technology method of the number of sampling points, designed the mathematical model that the measurement relative deviation determined by the combination of points is less than the analysis allowable difference to calculate the overall acceptability rate, in practice, the measurement results of each point and the statistical analysis point are obtained according to the specific test method Combining the results,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap