Locking assembly and ground anchor with same

A component and locking technology, applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., can solve the problem of time-consuming and labor-intensive fixing of pipelines, and achieve the effect of saving installation time, simple structure and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

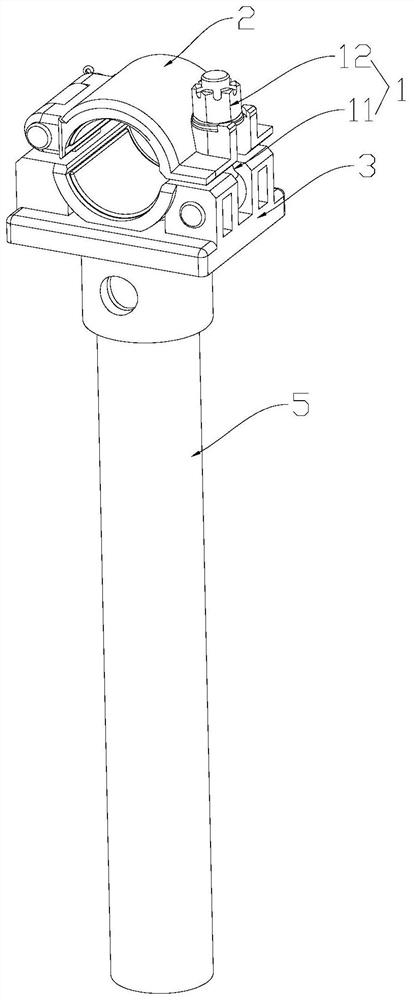

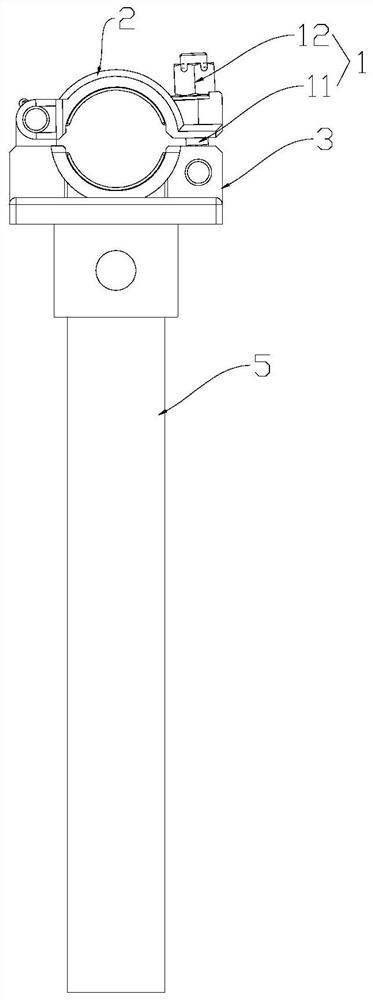

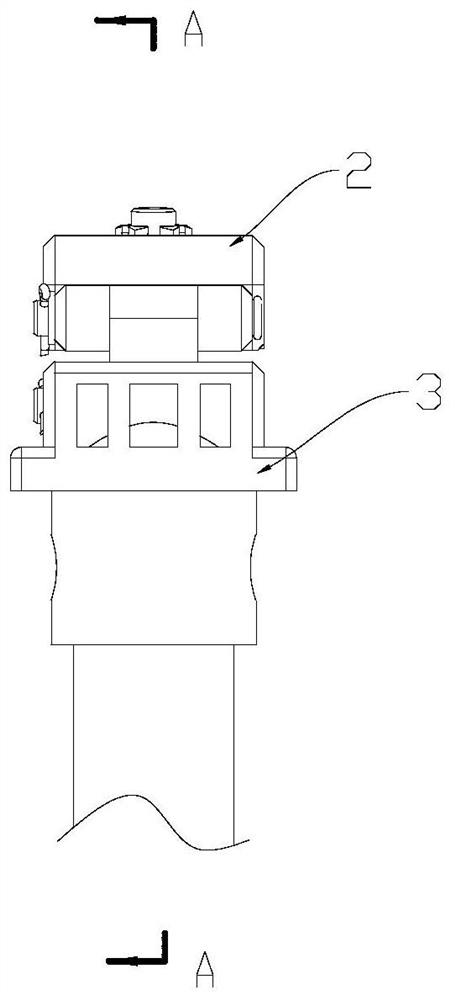

[0033] Such as Figure 1-Figure 7 , this embodiment provides a locking assembly 1, including a rotating body 11 and a locking member 12 located on the rotating body 11, wherein: the rotating body 11 is connected to any one of the ground anchor body 3 and the gland 2 and the other of the two is provided with a receiving part; the rotating body 11 can be rotated into the receiving part, and the position of the locking part 12 on the rotating body 11 can be adjusted until the locking part 12 abuts against the receiving part to push the pressure The cover 2 is fastened to the ground anchor body 3; at the same time, the pipeline between the gland 2 and the ground anchor body 3 can be fixed.

[0034] Further, the rotating body 11 can extend into the receiving part from the side of the receiving part by turning, and the locking part 12 located above the receiving part can adjust the position on the rotating body 11 until the locking part 12 abuts against the receiving part .

[0035]

Embodiment 2

[0055] This embodiment provides a ground anchor, see Figure 1-Figure 4 As shown, the above-mentioned ground anchor includes a ground anchor body 3, a gland 2 and the above-mentioned locking assembly 1. The first side of the ground anchor body 3 and the gland 2 is fastened by the locking assembly 1, and the second side of the two is hinged.

[0056] In the ground anchor in this embodiment, the first side of the ground anchor body 3 and the gland 2 are fastened by the locking assembly 1, and the second side of the two is hinged; the ground anchor body 3 and the gland 2 are hinged together, and the fixed After the pipeline is finished, it is only necessary to rotate the rotating body 11 on one side and tighten a locking piece 12 to complete the assembly of the gland 2 and the ground anchor body 3. Compared with the prior art and the ground anchor body 3 and the gland 2 In terms of the structure in which the above-mentioned locking assembly 1 is used to fix both sides of the structu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap