Continuous dry-method ball mill with ultrahigh filling rate

A technology of dry ball milling and filling rate, which is applied in grain processing, etc., can solve problems such as insufficient filling rate, unsatisfactory quality and efficiency of ball milling operations, and achieve the effect of improving filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020]Example one

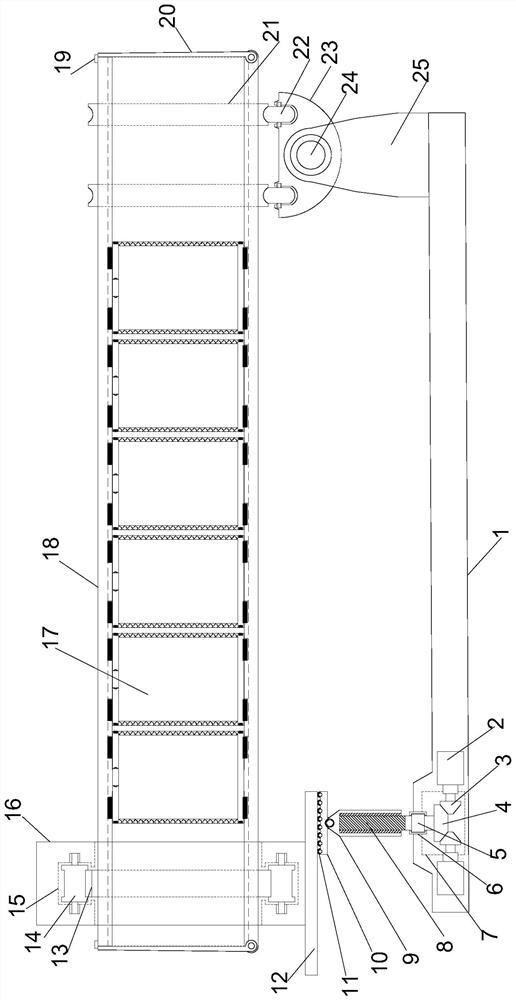

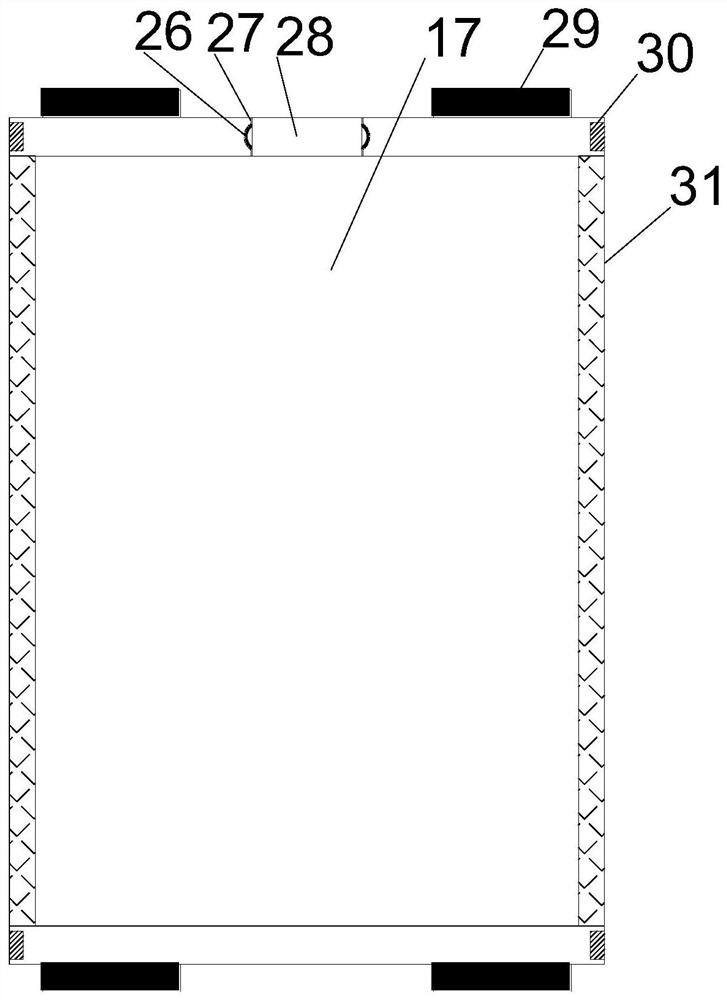

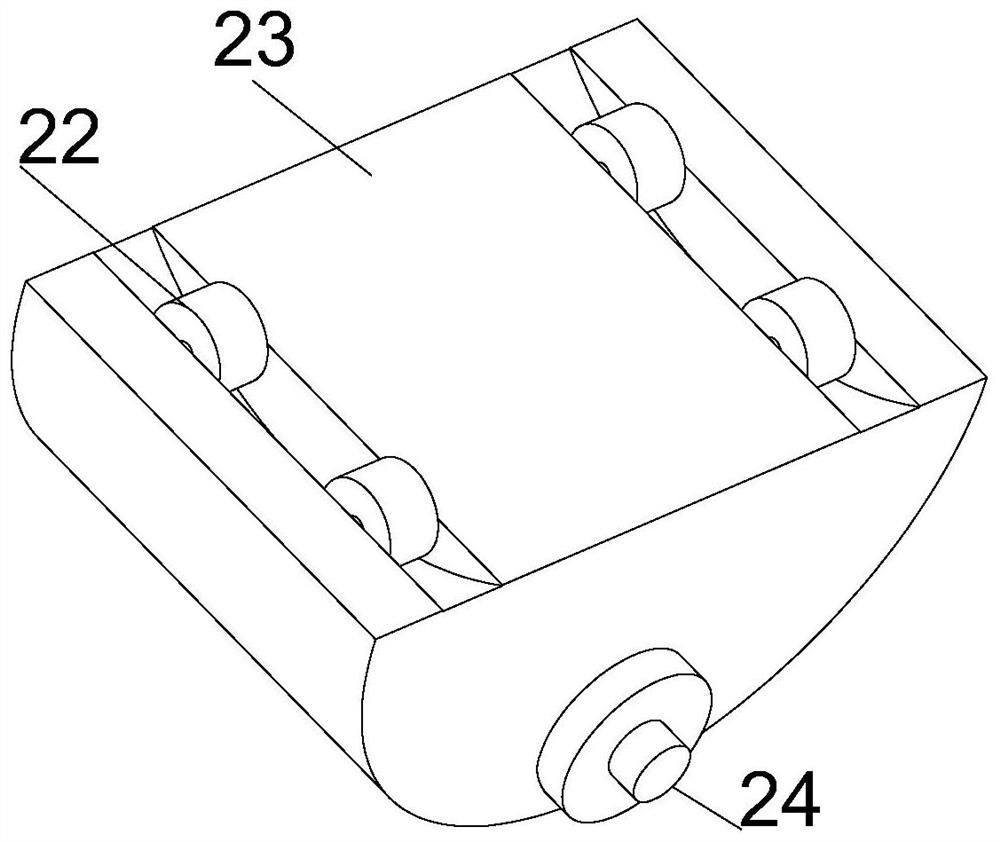

[0021]SeeFigure 1 ~ 3In the embodiment of the present invention, an ultra-high filling rate continuous dry ball mill, including a horizontally disposed support mounting plate 1, and the upper right upper end of the support mounting plate 1 is vertically provided with support mounting frame 25, support the upper end of the mounting frame 25. The rotating mounting plate 23 is provided by the support shaft 24, and the support mounting plate 1 is disposed laterally, and the two ends of the rotating mounting cylinder 18 are configured to rotate the shutter 20, and the outer end of the rotation gate 20 is connected. The buckle 19 is fixed to the rotating mounting cartridge 18, and the upper tethanum of the rotating mounting plate 23 is provided by the rotating shaft to set the finite bonding wheel 22, and the left and rear sides are located outside the outer side of the rotating mounting cartridge 18. The rotating ring 21, the left end of the support mounting plate 1 is vert

Example Embodiment

[0023]Example 2

[0024]On the basis of the first example, the drive motor 2 is activated such that the driving cone gear 3 mates engagement transmission, realizing the restricted rotation shaft 5 and the lifting stud 8 synchronously, the lifting screw 9 cooperates with the elevator The column 8 achieves lifting adjustment, at which time the rotating support plate 10 and its support guide wheel 11 mitigate the inclination of the positioning support plate 12, it is finally achieved the inclination of the rotating mounting tube 18, and the introduction and export of the ball milling feedstock, rotate mounting When the barrel 18 is rotated, the support rotating shaft 24 and the rotating mounting plate 23 make the rotation process continuously stabilize and does not affect the progression of the ball mill.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap