Telescopic roadway gangue filling machine for underground coal mine

A telescopic and filling machine technology, which is applied to filling materials, mining devices, mining equipment, etc., can solve the problems of frequent dismantling of the intermediate frame of the belt conveyor and the number of unit motors, and achieve long travel distance, improve sliding efficiency, and stabilize the machine. body effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

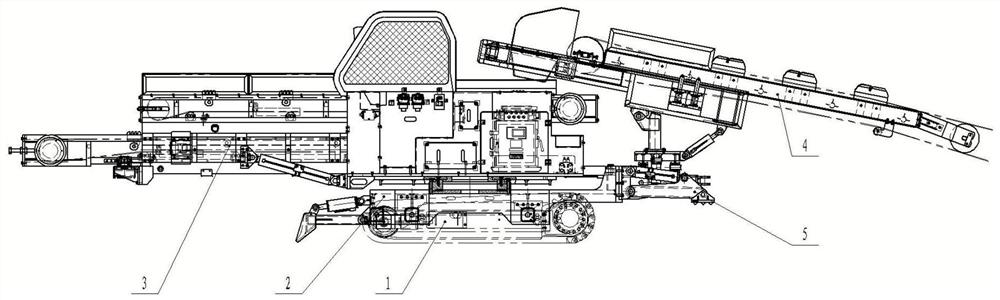

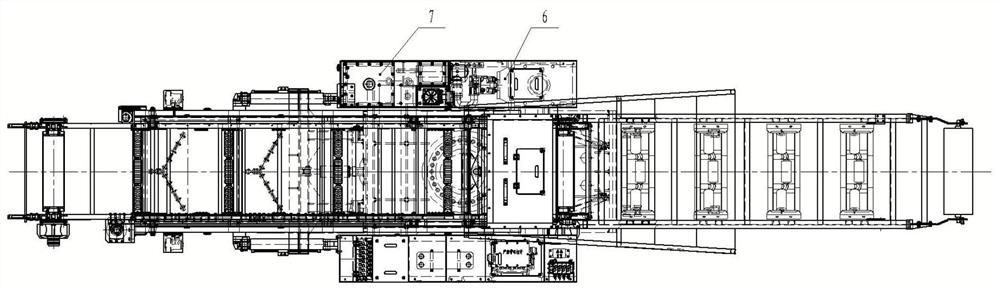

[0035]Such asFigure 1 to Figure 2 As shown, the retractable tunnel gangue filling machine for underground coal mines in this embodiment includes a walking part 1, a body part 2, a gangue throwing device 3, a discharge device 4, a rear support part 5, and an electrical system 6. And hydraulic system 7; the walking part 1 is arranged on the left and right sides below the body part 2, the gangue throwing device 3 is arranged in the middle of the body part 2, the unloading device 4 is arranged at the rear end of the body part 2, and the rear support part 5 The electric system 6 is arranged on the right rear side of the machine body 2 and the hydraulic system 7 is arranged on the right front side of the machine body 2.

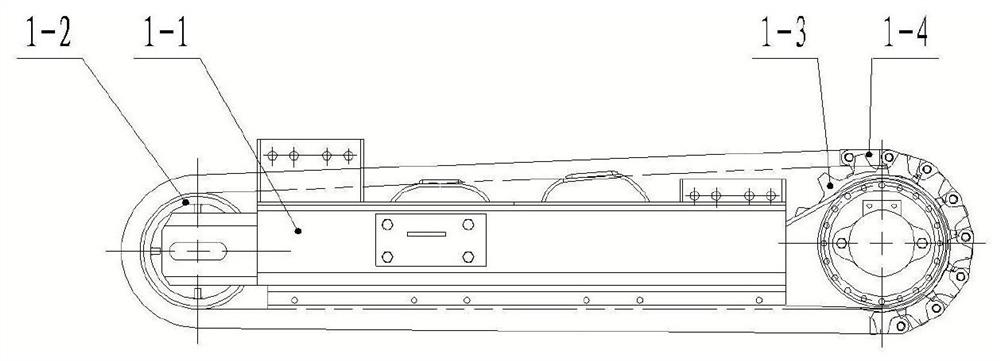

[0036]Such asFigure 3 to Figure 4 As shown, the walking part 1 consists of a crawler frame 1-1, two reversing sprockets 1-2, two drive sprockets 1-3, two pairs of crawler belts 1-4, and two tensioning devices 1-5, The reducer 1-6 and the walking hydraulic motor 1-7 are compose

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap