Tractor, track transfer device and track transfer method of the tractor

A technology of iron bulls and rails, applied in the field of road construction, can solve the problems of easy derailment of outer wheels, unfavorable movement of iron bulls, and acceleration of outer rails, etc., to achieve the effect of reducing time, reducing friction, and slowing down the wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-7 The application is described in further detail.

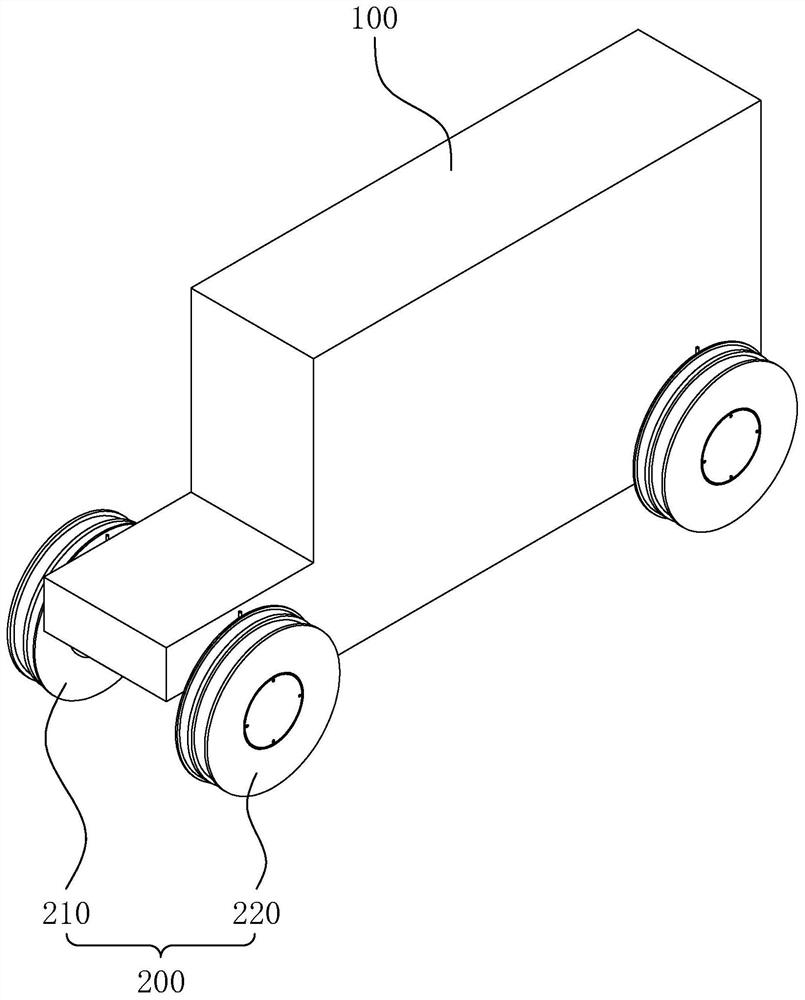

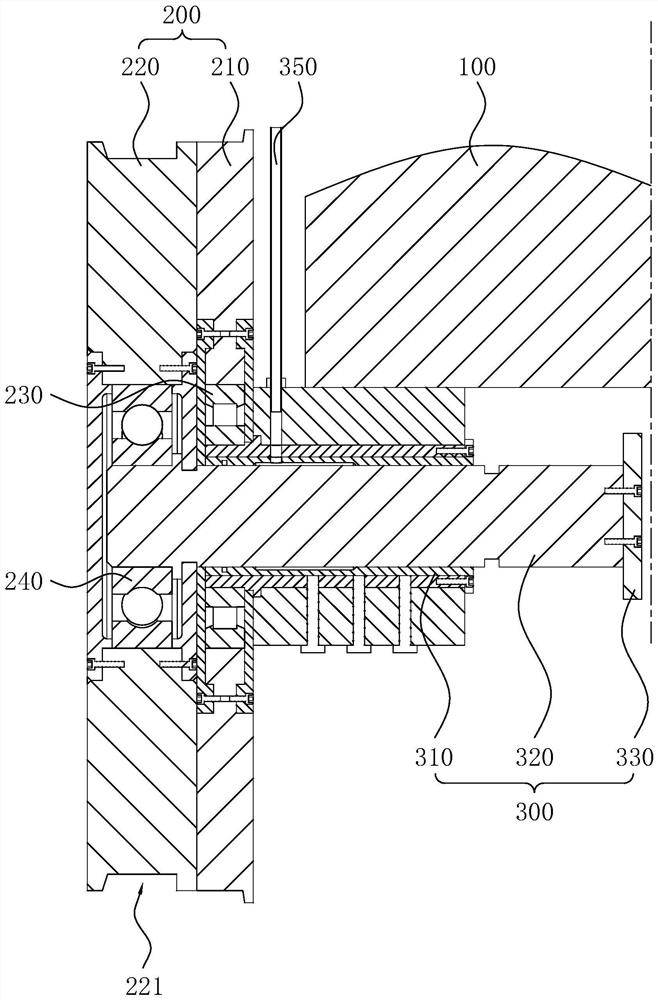

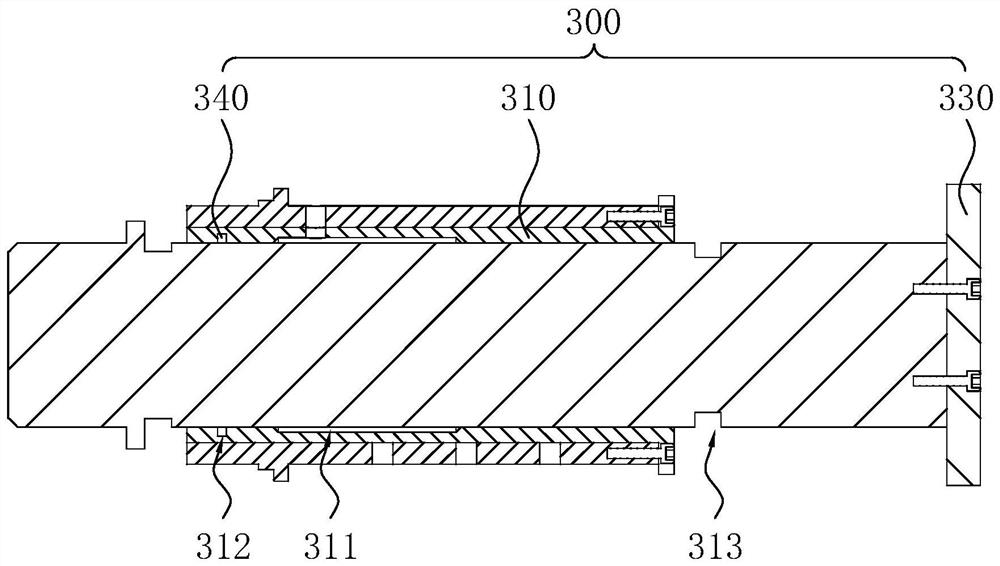

[0046] The embodiment of the present application discloses an iron cow. refer to figure 1 and figure 2 , the iron cow includes a vehicle frame 100, and the vehicle frame 100 is provided with a running device 200 for the vehicle frame 100 to walk on the track. The walking device 200 includes at least four inner wheels 210 and at least four outer wheels 220 . In the embodiment of the present application, there are four inner wheels 210 and four outer wheels 220 , and one inner wheel 210 corresponds to one outer wheel 220 . The inner wheel 210 rolls on the inner track 420 and the outer wheel 220 can roll on the outer track 410 . The traveling device 200 also includes a telescopic mechanism 300 for adjusting the relative position of the outer wheel 220 and the vehicle frame 100 , so as to make the outer wheel 220 roll on the outer track 410 or suspend the outer wheel 220 .

[0047] re

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap