Direct current signal adapter with feedback and intelligent electromagnetic pulse valve comprising same

An electromagnetic pulse valve and DC signal technology, applied in the field of pulse valves, can solve problems such as affecting the control accuracy, unable to clearly know the working state and damage state of the electromagnetic pulse valve, unable to directly collect control signals, etc., so as to improve the control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] Example one

[0047] Figure 4 It is a schematic structural diagram of a DC signal adapter with feedback in accordance with an embodiment of the present application, such as Figure 4 As shown, the direct current signal adapter 800 of the feedback includes a pulse valve control circuit 810, a control signal terminal 830, a collector terminal 840, and a pulse valve signal feedback circuit 860.

[0048] The pulse valve control circuit 810 is configured to connect to the coil of the electromagnetic pulse valve A.

[0049] The input end of the control signal terminal 830 is configured to connect the control device 910 of the electromagnetic pulse valve A, which is connected to the pulse valve control circuit 810 with the pulse valve control circuit 810.

[0050] The input end of the collector terminal 840 is connected to the wire, and the output of the collector terminal 840 is used to connect to the data collector 920.

[0051] The input end of the pulse valve signal feedback circ

Example Embodiment

[0062] Example 2

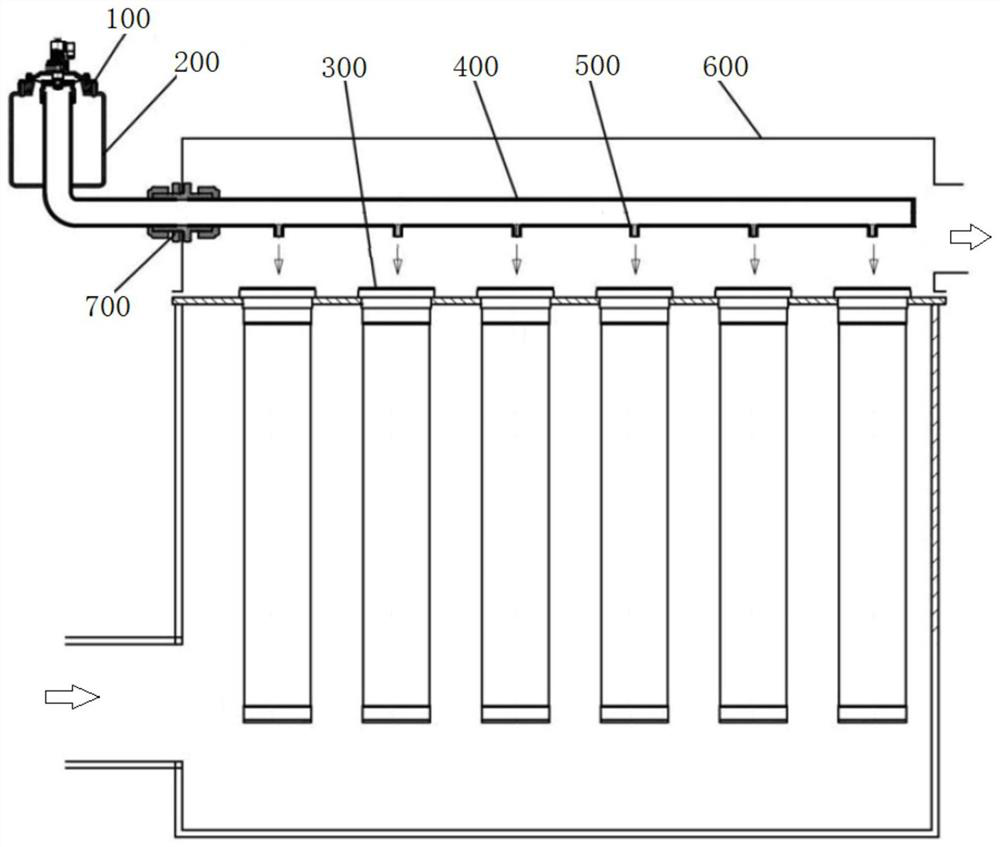

[0063] Based on the inventive concept of a DC signal adapter with feedback in the foregoing embodiment, the present invention also provides an intelligent electromagnetic pulse valve containing the DC signal adapter, the intelligent electromagnetic pulse valve including an electromagnetic pulse valve. A and the feedback of DC signal adapter 800.

[0064] The electromagnetic pulse valve A may be a right angle electromagnetic pulse valve, a submerged electromagnetic pulse valve 100 or a straight-through electromagnetic pulse valve.

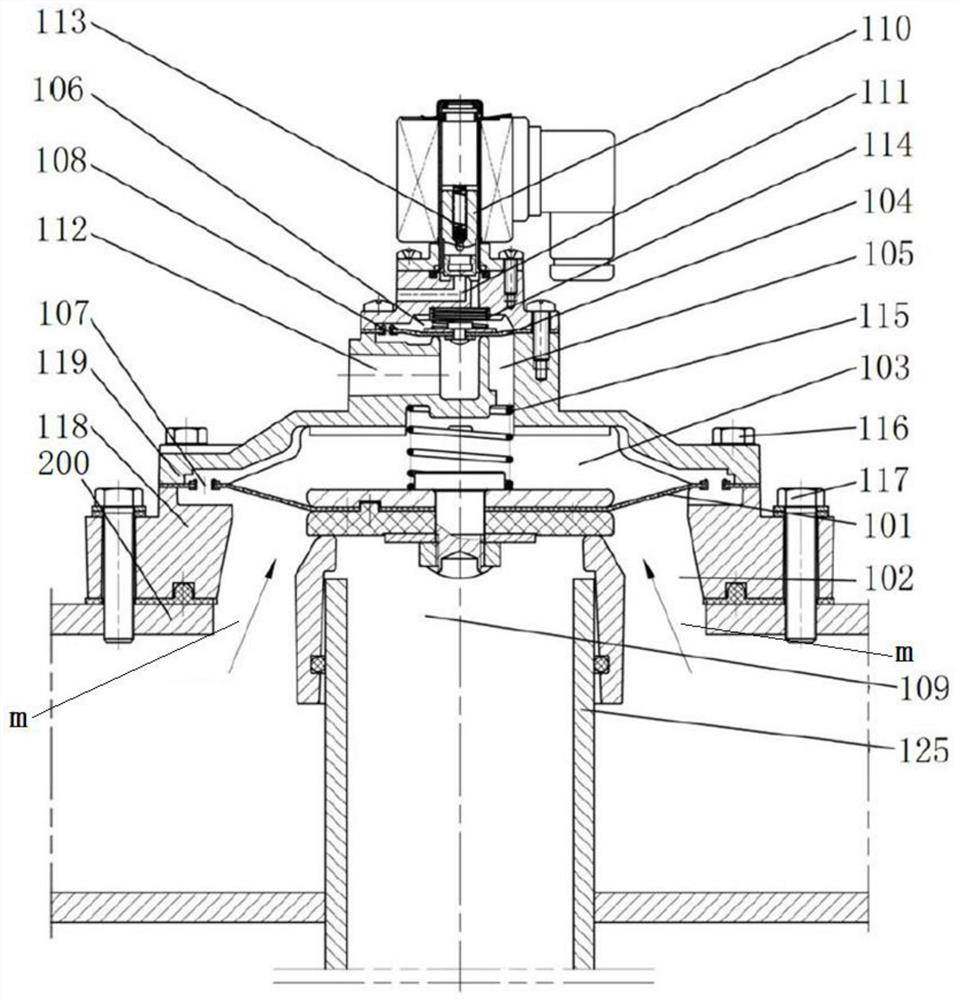

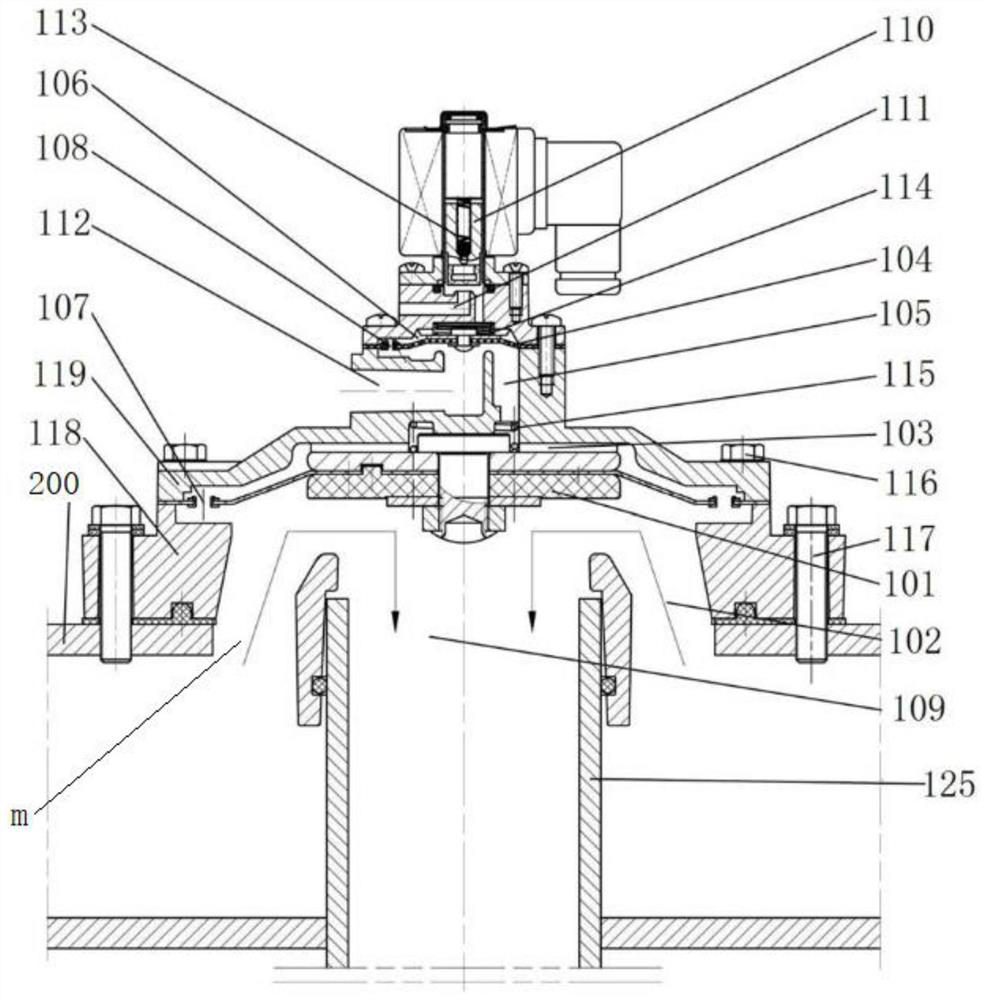

[0065] In the present embodiment, the electromagnetic pulse valve A is the submerged electromagnetic pulse valve 100, the submerged electromagnetic pulse valve 100 includes a valve body 118, an intake port M, an output port 109 for closing or opening. The driving electrical component of the output port 109 includes the coil and a main film 101 for covering the outlet, the main film 101 and the valve body 118. The compression spring 115 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap