Closed precise flow control mechanism

A flow control, airtight technology, applied in the direction of mechanical equipment, engine components, valve details, etc., can solve problems such as the environment where oxygen or hydrogen cannot be used, the structure of the solenoid valve is not reasonable, the structure of the intake air is not stable enough, etc., to facilitate processing , Improve control accuracy and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

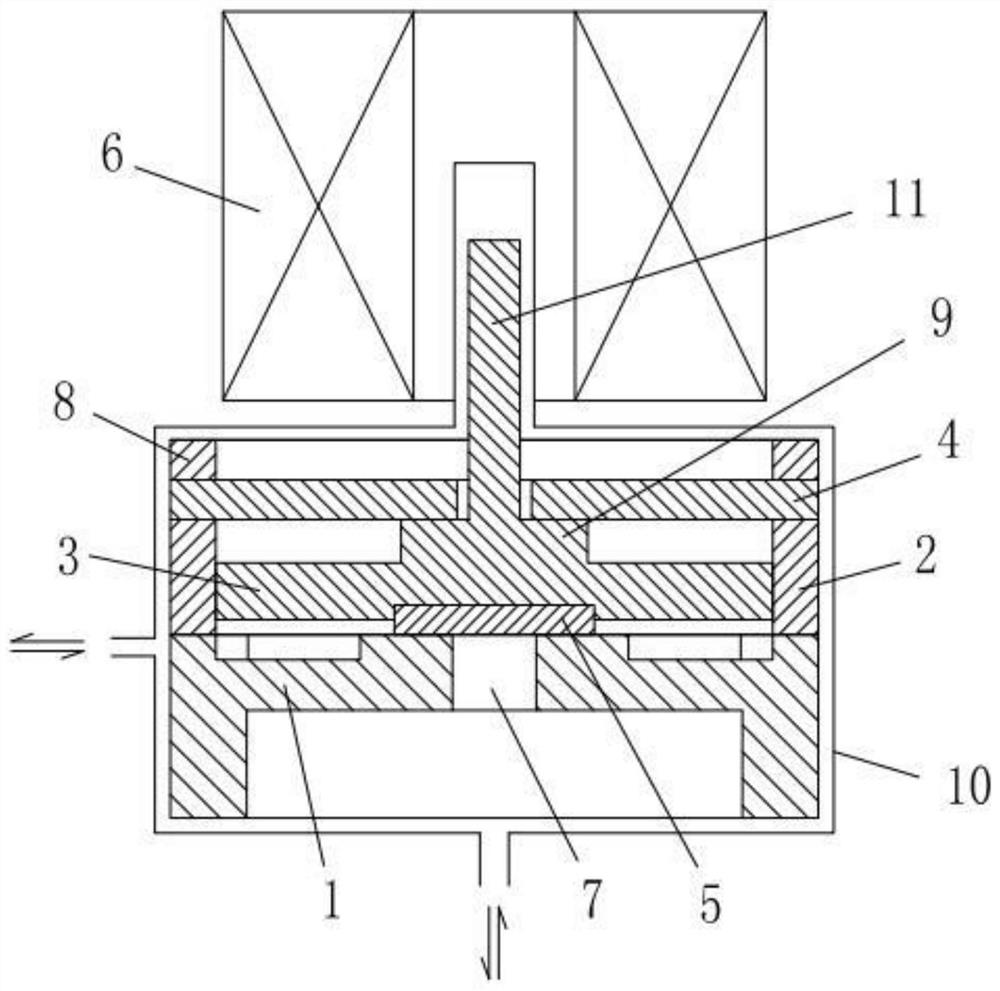

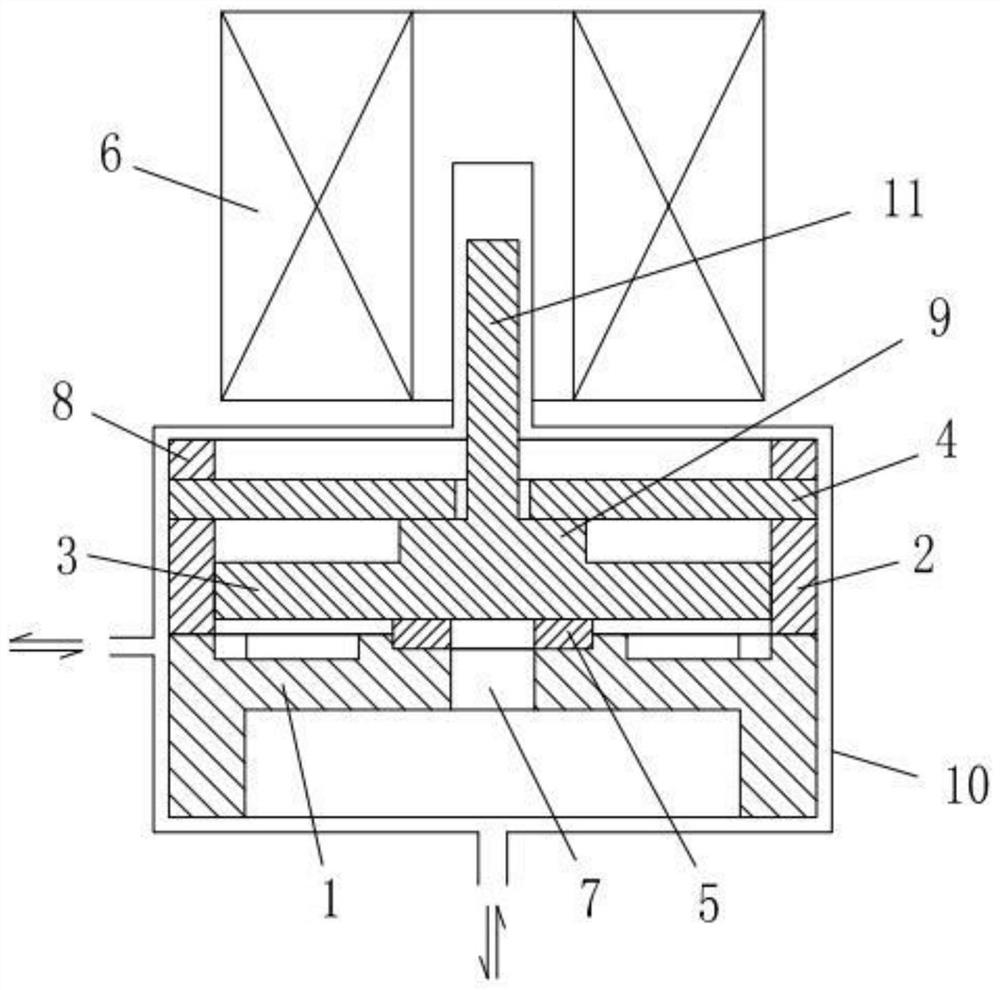

[0016] like Figure 1-2 As shown in the figure, a closed precision flow control mechanism according to the present invention includes a closed space 10 and an electromagnetic coil 6. The closed space 10 can be a shell structure made of materials such as plastic or metal. The closed space 10 is provided with a base 1, Ring base 2 , floating part 3 , elastic sheet 4 , gasket 5 and backing ring 8 .

[0017] The center of the base 1 is provided with a flow channel hole 7, the outer circumference of the upper side of the base 1 is provided with a plurality of arc-shaped baffle walls, the upper surfaces of the multiple arc-shaped baffle walls are flush, and the ring seat 2 is located on the outer circumference of the base 1. On the arc-shaped baffle walls, a fluid circulation opening structure is formed between adjacent arc-shaped baffle walls;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap