Spin welding system

A technology of rotary welding and welding mechanism, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor cost and low efficiency, and achieve the effect of overcoming high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

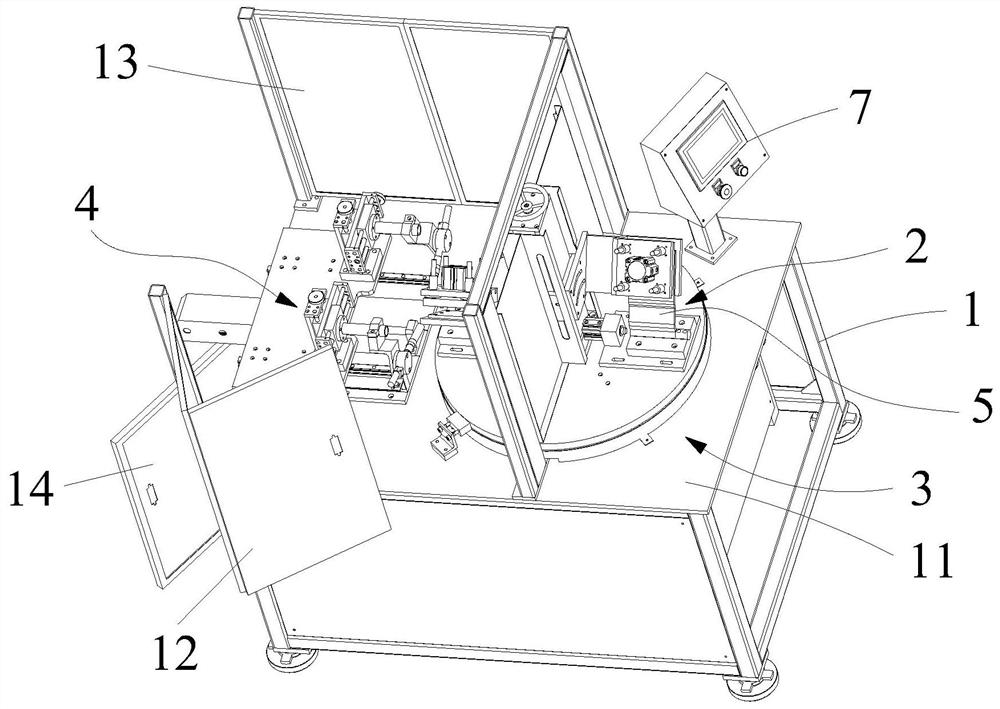

[0039] figure 1 It is a structural diagram of the spin welding system of the present invention.

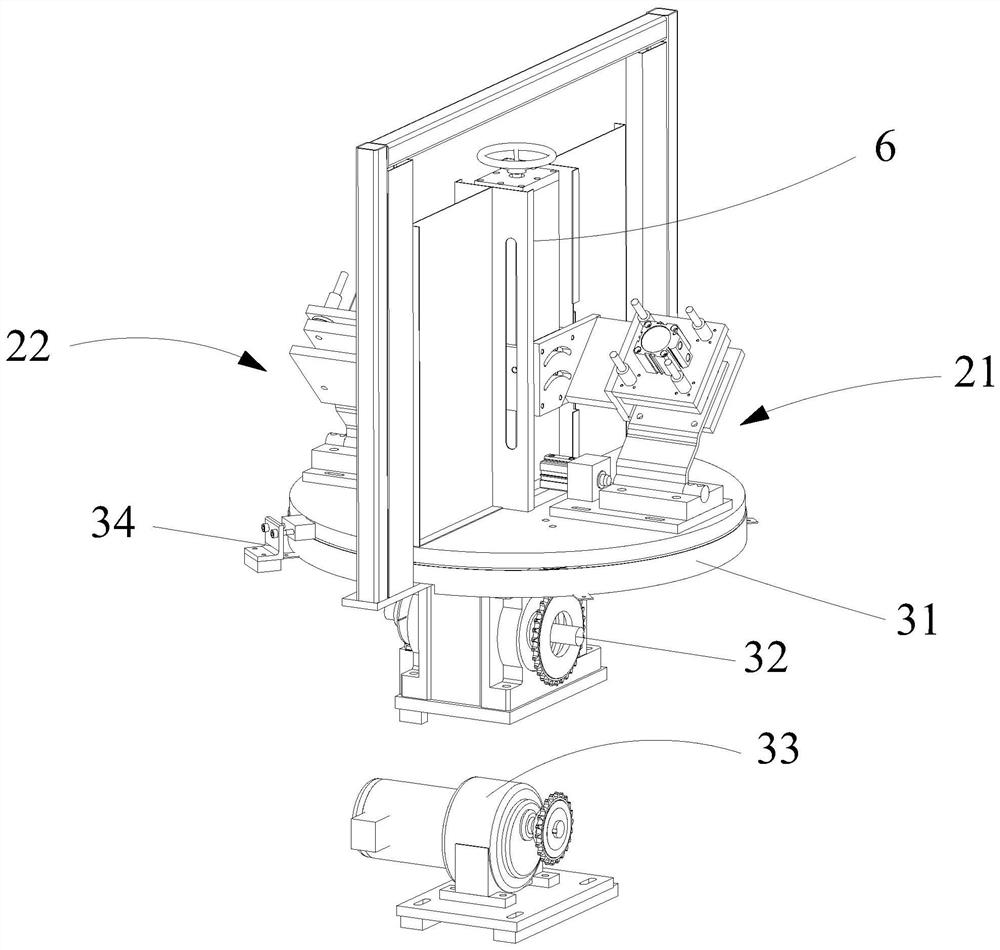

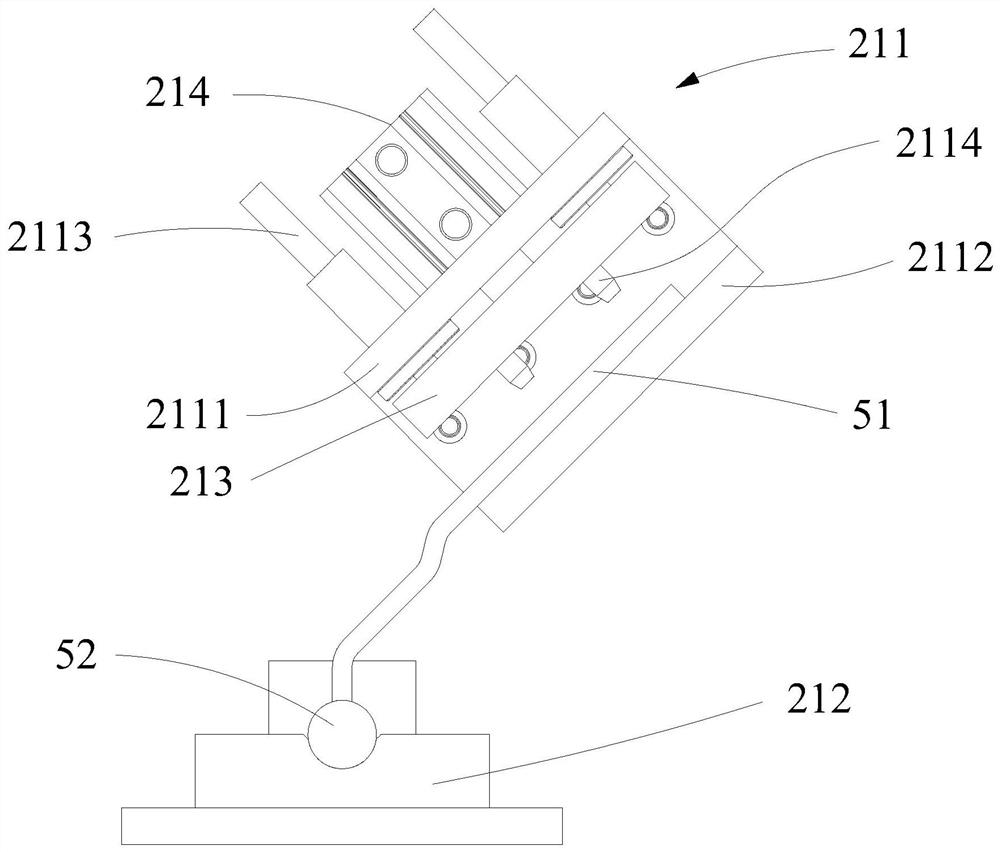

[0040] In this example, if figure 1As shown, the present embodiment provides a rotary welding system, which includes: a control module, a mounting bracket 1, a workpiece fixing mechanism 2, a turntable mechanism 3 and a welding mechanism 4; wherein the turntable mechanism 3 and the welding mechanism 4 are horizontally arranged on On the mounting bracket 1, the workpiece fixing mechanism 2 is located on the turntable mechanism 3, and the workpiece fixing mechanism 2, the turntable mechanism 3 and the welding mechanism 4 are all electrically connected to the control module; the workpiece fixing mechanism 2 is suitable for placing Welding the workpiece 5, the control module is suitable for controlling the workpiece fixing mechanism 2 to lock the workpiece 5 to be welded; the control module is suitable for driving the turntable mechanism 3 to drive the workpiece fixing mechanism 2 to ro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap