Cutting device for machining of mechanical parts

A technology for cutting devices and mechanical accessories, applied in shearing devices, metal processing equipment, accessories of shearing machines, etc., can solve the problems of inconvenient access to accessories, inability to maintain a stable position of accessories, and affecting the accuracy of cutting dimensions of accessories, etc. Achieve the effect of solving the unstable position, convenient and quick access, and efficient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

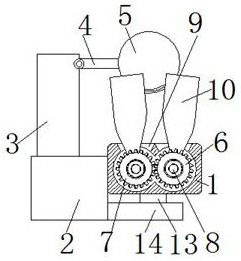

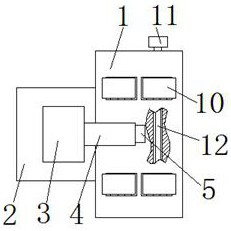

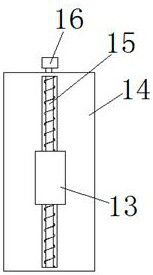

[0020] In this embodiment one, refer to Figure 1-4 , a cutting device for processing mechanical parts, comprising a base 14, the upper surface of the base 14 is provided with a straight groove along its length direction, and a lead screw 15 is installed in the straight groove through the screw bearing to rotate, and the lead screw 15 is screwed with a moving Seat 13, the top of mobile seat 13 is provided with console 1, and the inside of console 1 is respectively provided with driving wheel 6 and driven wheel 7 that keep mutually meshing relationship near its two ends, the driving wheel 6 and driven wheel 7 The center is respectively provided with a rotating shaft 8, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap