Large-temperature-rise two-stage second-class lithium bromide absorption heat pump water heater

A lithium bromide absorption and heat pump hot water technology, which is applied to adsorption machines, machines using waste heat, refrigerators, etc., can solve problems such as poor parameter conditions, inability to achieve large temperature rise of heat sources, and large cooling range of waste heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

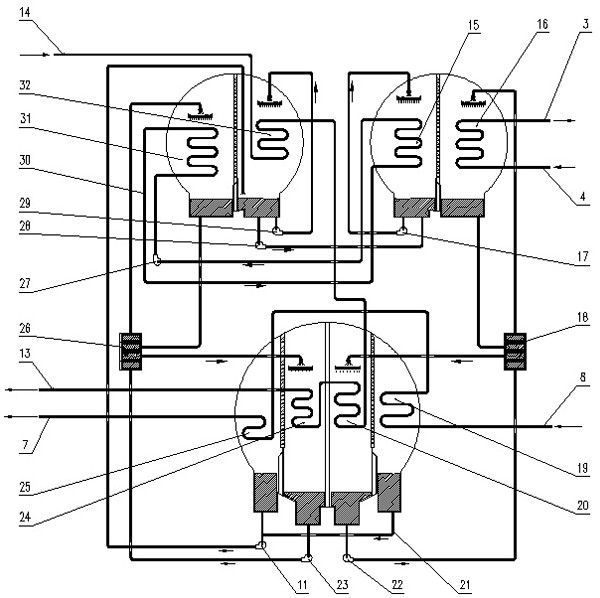

[0014] see figure 2 , the present invention relates to a large temperature rise two-stage type II lithium bromide absorption heat pump hot water unit, including a high temperature evaporator 15, a high temperature absorber 16, a high temperature generator 20, a high temperature condenser 19, and a high temperature solution heat exchanger 18 , low temperature evaporator 32, low temperature absorber 31, low temperature generator 24, low temperature condenser 25, low temperature solution heat exchanger 26, high temperature solution pump 22, high temperature refrigerant circulation pump 17, low temperature solution pump 23, low temperature refrigerant circulation pump 29. Condenser refrigerant pump 11, refrigerant lifting pump 28, internal circulation hot water pump 27, and pipelines, valves and control systems connecting the various components. The solution circulation on the high temperature side of a single-effect type II heat pump is composed of a high temperature evaporator 15,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap